Stirring type sample mixing device

A stirring and sample preparation technology, which is applied to mixer accessories, mixers with rotary stirring devices, chemical instruments and methods, etc., can solve problems such as the inability to truly reflect the oil displacement effect of the composite system, and ensure uniformity and stability. , the effect of accuracy assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

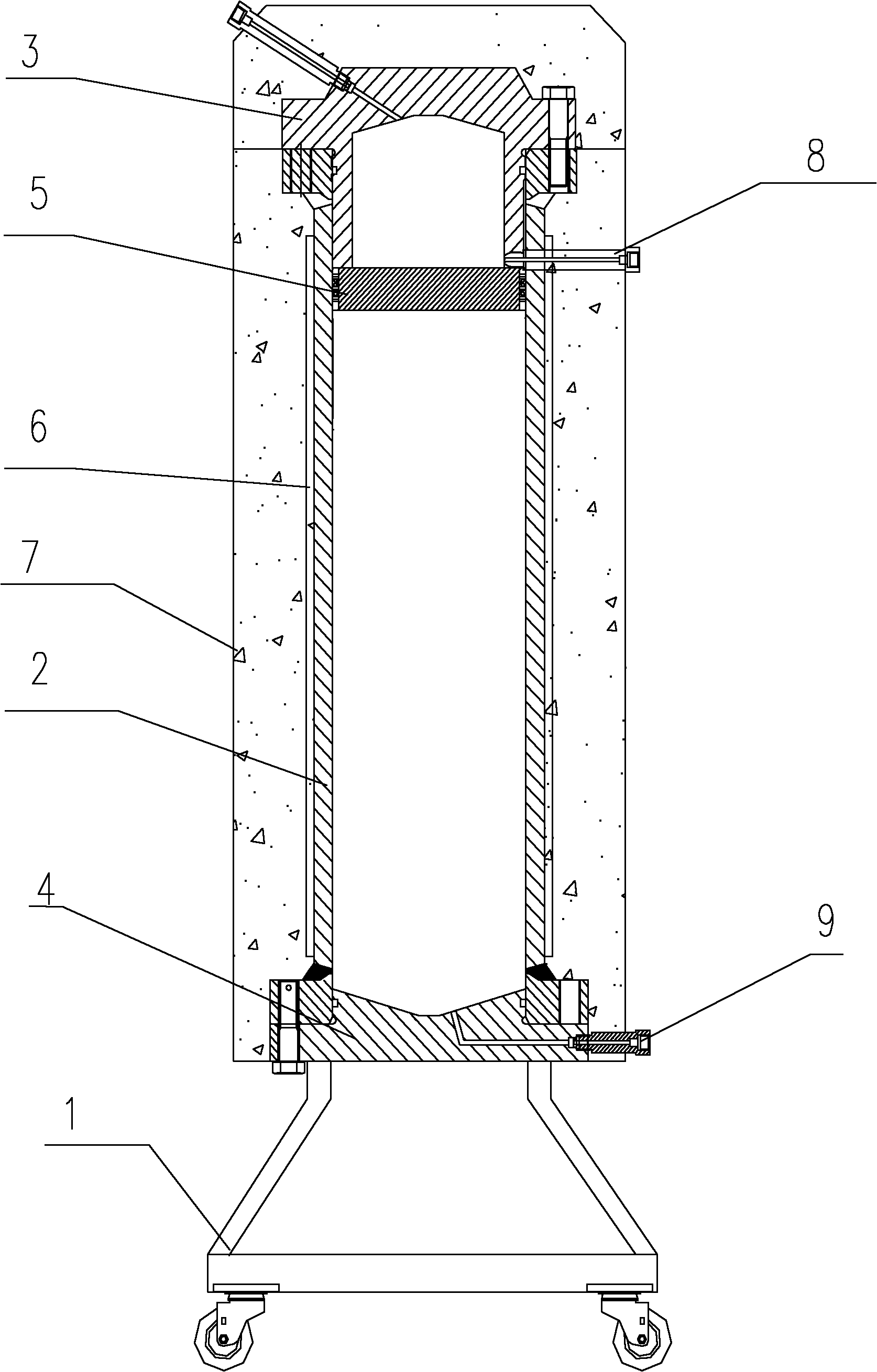

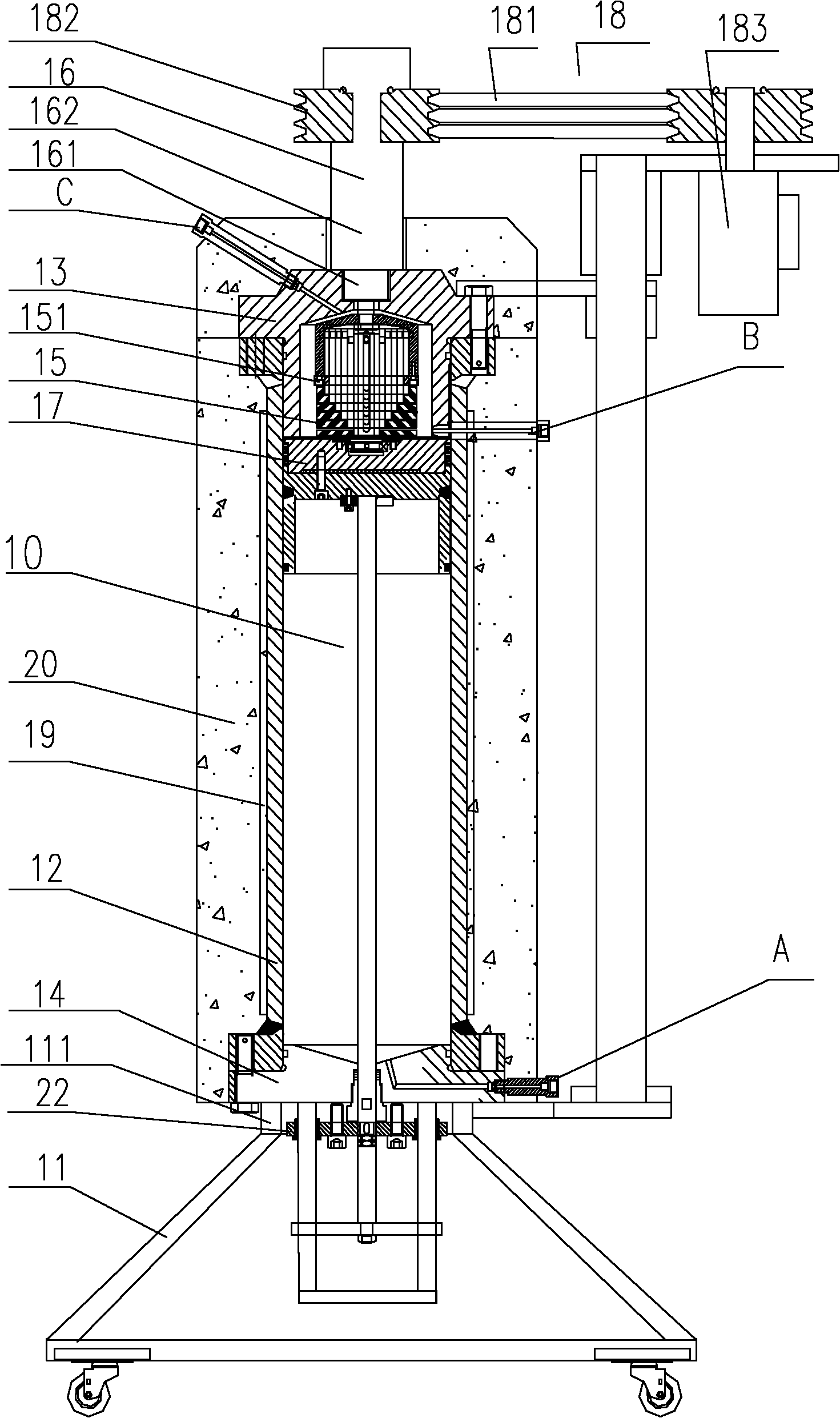

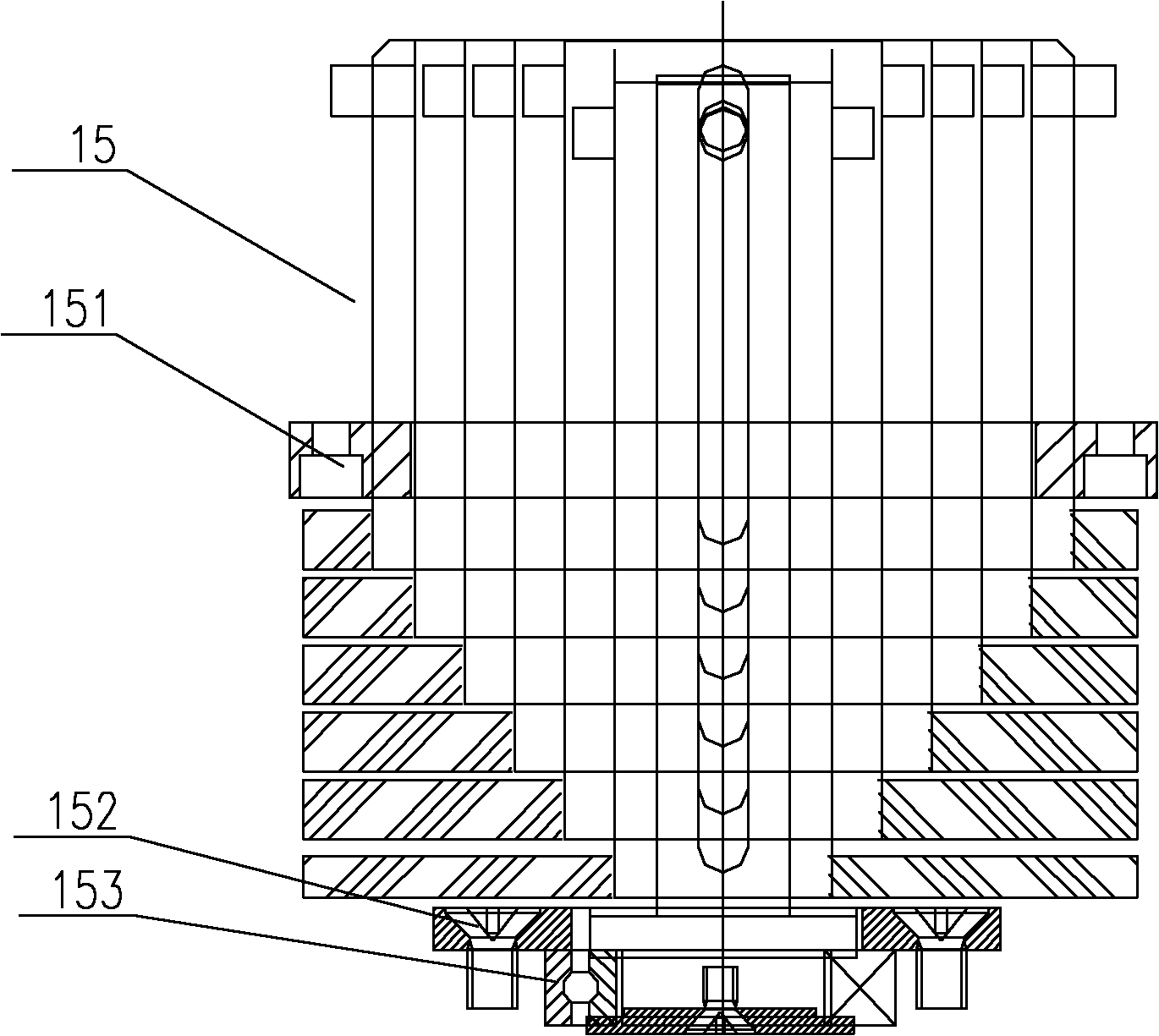

[0019] Depend on figure 2 As shown, the stirrable sampler includes a cylinder 10, a bracket 11, a stirring paddle 15, a magnetic coupling rotating mechanism 16, a floating piston 17, a power transmission mechanism 18, a heating ring 19, and a heat preservation cover 20. The bracket 11 includes an upper supporting plate 111 and supporting legs, the upper supporting plate 111 is fixed on the bottom of the cylinder, and the bottom of the supporting legs can be provided with a pulley for the convenience of operation; the outer wall of the cylinder 10 is sequentially covered with a heating ring 19 and a heat preservation cover 20; wherein the cylinder 10 Including the cylinder body 12, the upper head 13 and the lower head 14, the upper and lower edges of the cylinder body 12 are respectively threaded and sealed with the upper head 13 and the lower head 14, so as to ensure that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com