Catalysis system and method for preparing diolefin copolymer elastomer

A catalytic system and elastomer technology, applied in the field of catalytic systems, can solve the problems of difficult separation and removal of solvents, low cis content, etc., and achieve the effects of good stability, high orientation and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Under the protection of nitrogen, add 0.031mmol of neodymium isooctanoate, 0.77mmol of triisobutylaluminum, 0.023mmol of dibutylaluminum hydride, 0.93mmol of chloroform, and 0.025mmol of ethyl trichloroacetate into the dry catalyst preparation device , 0.009 mmol of octanoic acid and 0.09 mmol of ethanol were evenly mixed and then aged at 30° C. for 50 min to prepare a homogeneous catalyst system for future use.

[0026] Add 23 mL of butadiene / isoprene hexane solution (wherein [Bd]=3.1mol / L, [Ip]=1.3mol / L) into the dry polymerization reactor under the protection of nitrogen, and then add the above-prepared Catalyst solution, the molar ratio of catalyst component A (neodymium isooctanoate) to total monomer is 3.0×10 -4 . After polymerization for 3 hours at 50°C, add 1 wt% of 2,6-di-tert-butyl-p-methylphenol in ethanol solution to terminate the reaction, wash it and place it in a vacuum oven at 45°C to dry to constant weight. The yield of the copolymerization product is ...

Embodiment 2

[0028] Under the protection of nitrogen, add 0.16mmol neodymium octanoate, 0.082mmol ethanol, 1.52mmol triisobutylaluminum, 2.74mmol chloroform, 0.10mmol ethyl chloroacetate, 0.048mmol isooctanoic acid and 0.005mmol Mmol capric acid was mixed uniformly and then aged at 50°C for 1 h to prepare a homogeneous catalyst system for future use.

[0029] Under the protection of nitrogen, add 42 mL of butadiene / isoprene hexane solution (where [Bd]=2.3mol / L, [Ip]=0.5mol / L) into the dry polymerization reactor, and then add the above A good catalyst solution, the molar ratio of catalyst component A (neodymium octanoate) to monomer is 1.4×10 -3 . The polymerization was terminated after 1 hour at 50° C., and the termination and post-treatment methods were the same as in Example 1. The copolymerization product yield is 41%, M w 1.5×10 6 ,M w / M n is 2.4, [η] is 4.3dL / g, the cis-1 and 4 contents of butadiene and isoprene chain members are 99.0% and 99.6%, respectively, and the butadiene...

Embodiment 3

[0031] Add 0.028mmol neodymium naphthenate, 0.003mmol ethanol, 0.92mmol triisobutylaluminum, 0.032mmol dibutylaluminum hydride, 0.08mmol chloroform and 0.008mmol isooctanoic acid to the dry catalyst preparation device under nitrogen protection , mixed evenly and aged at 10°C for 115h to prepare a homogeneous catalyst system for future use.

[0032] Add 42 mL of butadiene / isoprene hexane solution (wherein [Bd]=1.8mol / L, [Ip]=0.4mol / L) into the dry polymerization reactor under the protection of nitrogen, and then add the above prepared Catalyst solution, the molar ratio of catalyst component A (neodymium naphthenate) and monomer is 3.5 * 10 -4 . Polymerization was terminated at 50°C for 25 hours, and the termination and post-treatment methods were the same as in Example 1. Copolymerization product yield is 27%, M w 3.9×10 5 ,M w / M n is 2.9, [η] is 2.1dL / g, the cis-1 and 4 contents of butadiene and isoprene chain members are 98.0% and 98.8%, respectively, and the butadiene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

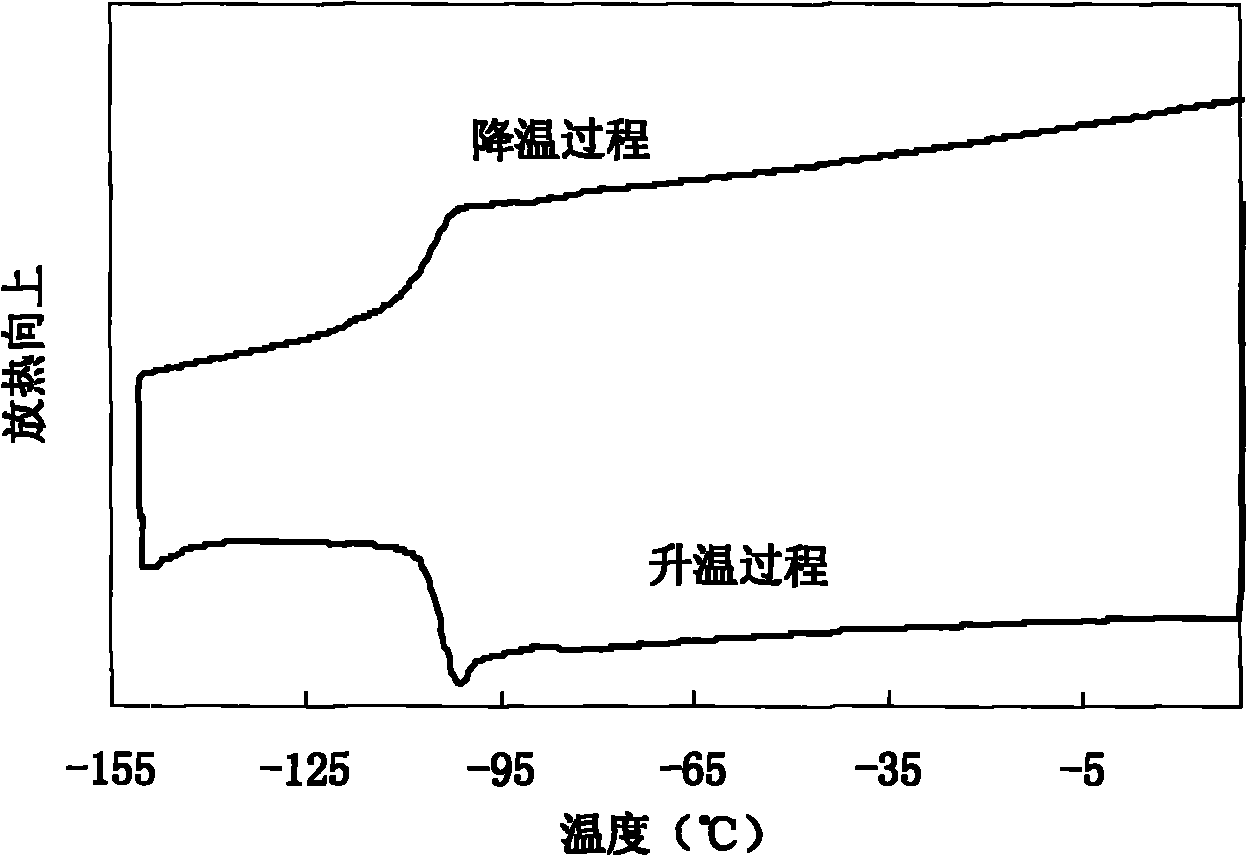

| glass transition temperature | aaaaa | aaaaa |

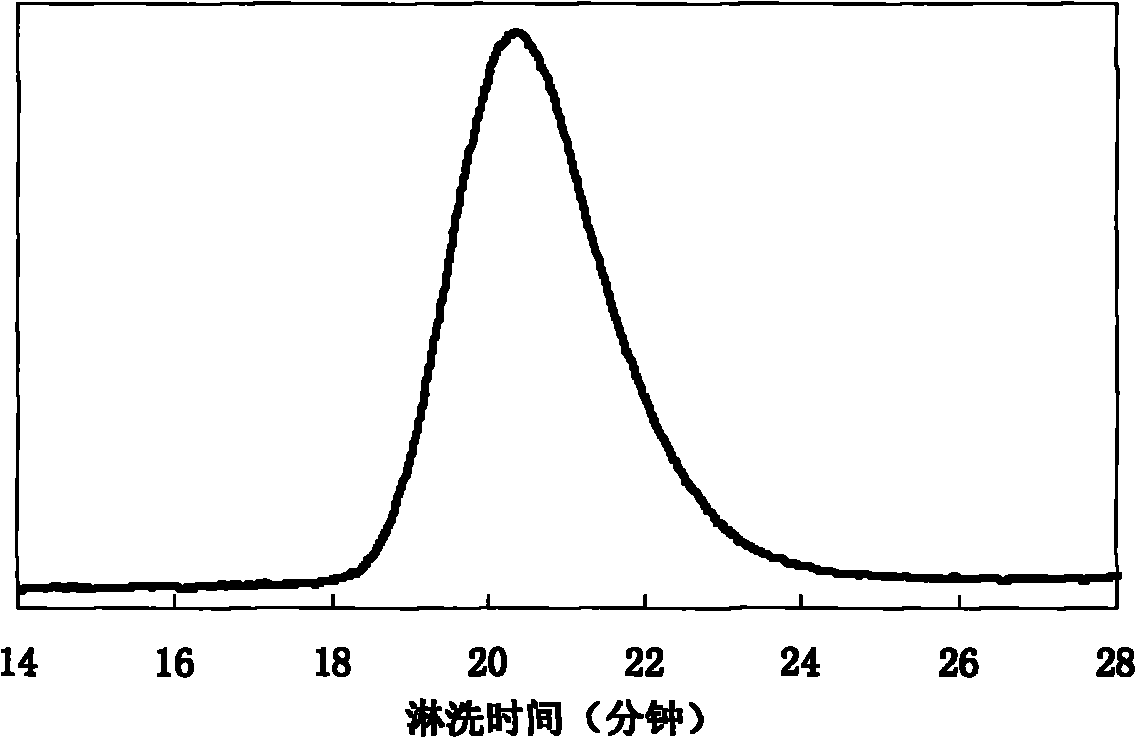

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com