Polarization-preserving type fiber integrated Michelson interferometer

An interferometer and polarization-maintaining fiber technology, applied in the field of fiber-optic interferometers, can solve the problems of low-noise, high-sensitivity, large polarization fluctuation and noise of the interferometer without considering the polarization state of the fiber, and achieve stable polarization state, high resistance to Strong interference ability and good temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

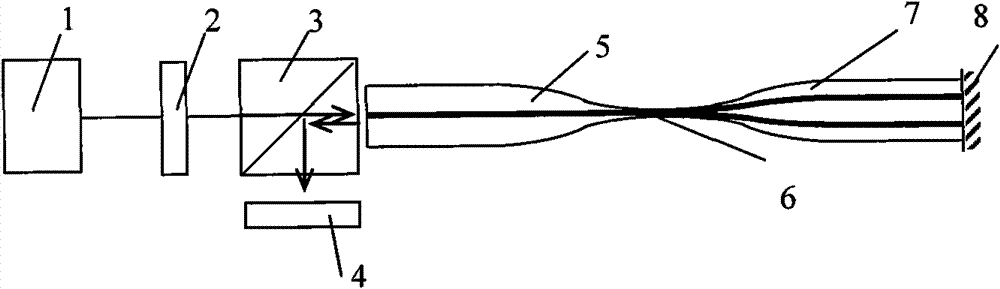

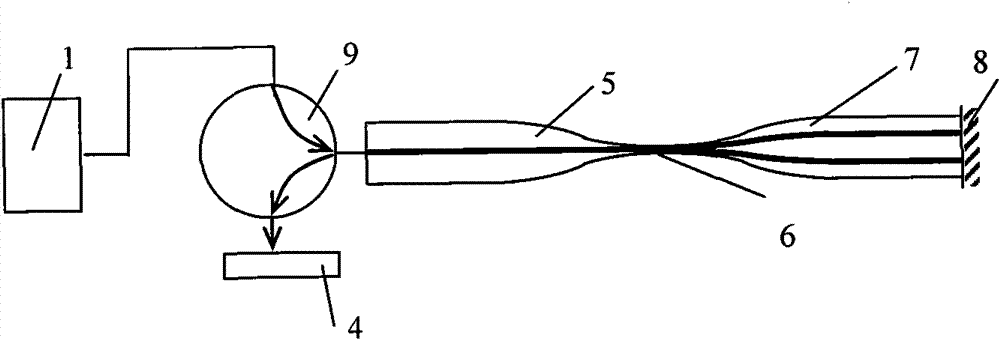

[0025] combine figure 2 , The second embodiment of the present invention is a polarization-maintaining fiber-integrated Michelson interferometer with a polarization circulator. On the basis of the first embodiment, the polarization circulator 9 is used to replace the optical isolator 2 and the micro beam splitter 3 .

specific Embodiment approach 3

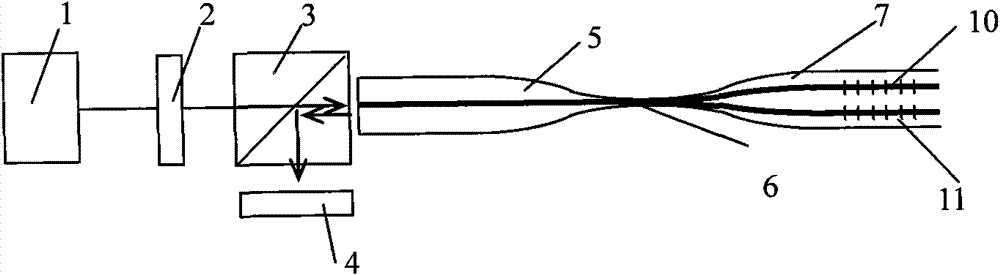

[0026] combine image 3 , the third embodiment of the present invention, compared with the first embodiment, is to replace the mirror 8 with a pair of fiber grating I 10 and fiber grating II 11 with the same reflection spectrum, and can also realize two coherent The optical arm is integrated into a single optical fiber with a polarization-maintaining fiber-integrated Michelson interferometer, and the fiber grating is written using phase mask technology. This structure can use broadband light as a light source due to the wavelength selectivity of the fiber grating.

specific Embodiment approach 4

[0027] combine Figure 4 , the fourth specific embodiment of the present invention, compared with the first specific embodiment, the light source and photodetector adopt separate light source 1 and photodetector 4, through the pigtail fiber 13 of light source pigtail 12 and photodetector and coupling device 14 connection. Both the light source pigtail 12 and the photodetector pigtail 13 are polarization maintaining fibers, and the coupler 14 is a polarization coupler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com