Method for synthesizing composite polycrystalline jadeite

A synthetic method and polycrystalline technology, which is applied in the field of compound polycrystalline jadeite jadeite synthesis, can solve the problems of harsh synthesis conditions, low conversion rate, and poor solid fluidity, and achieve simple reaction equipment, simple operation, and high transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

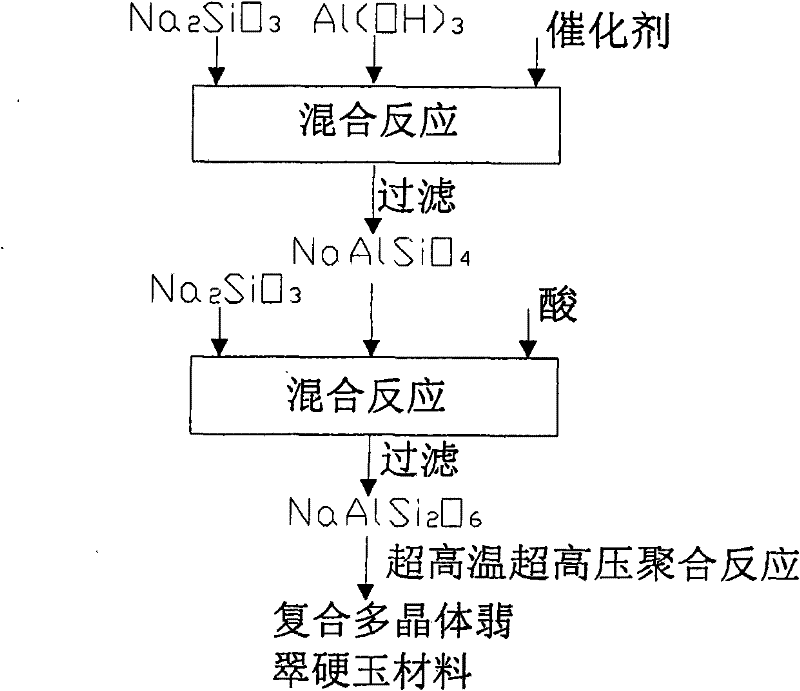

Method used

Image

Examples

Embodiment 1

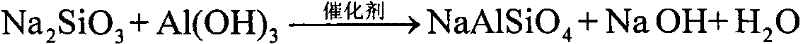

[0031] 1. Synthesis of sodium aluminum monosilicate solid powder

[0032] In the reactor, first add 120-300 mesh Al(OH) 3 Powder, sodium silicate aqueous solution and a small amount of NaOH catalyst, the molar ratio of aluminum hydroxide to sodium silicate is 0.5; the molar ratio of sodium hydroxide to aluminum hydroxide is 2.0. Heating to a temperature of 120° C. and maintaining the reaction for 2 hours, a solid precipitate of sodium aluminum monosilicate is produced, which is filtered to obtain a solid precipitate of sodium aluminum monosilicate.

[0033] (2) Synthesis of sodium aluminum disilicate solid powder

[0034] Disperse sodium sodium monosilicate solid in water, add inorganic acid solution to adjust the pH, pH = 3, then add sodium silicate solution in an equimolar amount to sodium aluminum silicate, maintain 10°C for 72 hours, stop the reaction, Sodium aluminum disilicate solid powder was obtained by filtration.

[0035] (3) Ultra-high temperature and ultra-high ...

Embodiment 2

[0038] 1. Synthesis of sodium aluminum monosilicate solid powder

[0039] In the reactor, first add 120-300 mesh Al(OH) 3Powder, sodium silicate aqueous solution and a small amount of NaOH catalyst, the molar ratio of aluminum hydroxide to sodium silicate is 0.6; the molar ratio of sodium hydroxide to aluminum hydroxide is 1.0. Heating to 60°C, and maintaining the reaction for 24 hours, a solid precipitate of sodium aluminum monosilicate is produced, which is filtered to obtain a solid precipitate of sodium aluminum monosilicate.

[0040] 2. Synthesis of sodium aluminum disilicate solid powder

[0041] Disperse sodium sodium monosilicate solid in water, add inorganic acid solution to adjust the pH, pH = 5, then add sodium silicate solution in an equimolar amount to sodium aluminum silicate, maintain 40°C for 48 hours, stop the reaction, Sodium aluminum disilicate solid powder was obtained by filtration.

[0042] 3. Ultra-high temperature and ultra-high pressure polymerizati...

Embodiment 3

[0045] 1. Synthesis of sodium aluminum monosilicate solid powder

[0046] In the reactor, first add 120-300 mesh Al(OH) 3 Powder, sodium silicate aqueous solution and a small amount of NaOH catalyst, the molar ratio of aluminum hydroxide to sodium silicate is 1.0; the molar ratio of sodium hydroxide to aluminum hydroxide is 0.2. Maintain the temperature of 10°C for 48 hours to produce sodium aluminum monosilicate solid precipitation, filter to obtain sodium aluminum monosilicate solid precipitation.

[0047] 2. Synthesis of sodium aluminum disilicate solid powder

[0048] Disperse sodium sodium monosilicate solid in water, add inorganic acid solution to adjust the pH, pH = 8, then add sodium silicate solution in an equimolar amount to sodium aluminum silicate, maintain 100°C for 12 hours, stop the reaction, Sodium aluminum disilicate solid powder was obtained by filtration.

[0049] 3. Ultra-high temperature and ultra-high pressure polymerization molding of sodium aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com