Crude benzene hydrofining method

A technology for hydrorefining and crude benzene, applied in chemical instruments and methods, hydrocarbons, organic chemistry, etc., can solve the problems of long process flow, low production efficiency, high energy consumption, etc., to simplify the refining process and reduce costs. , the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

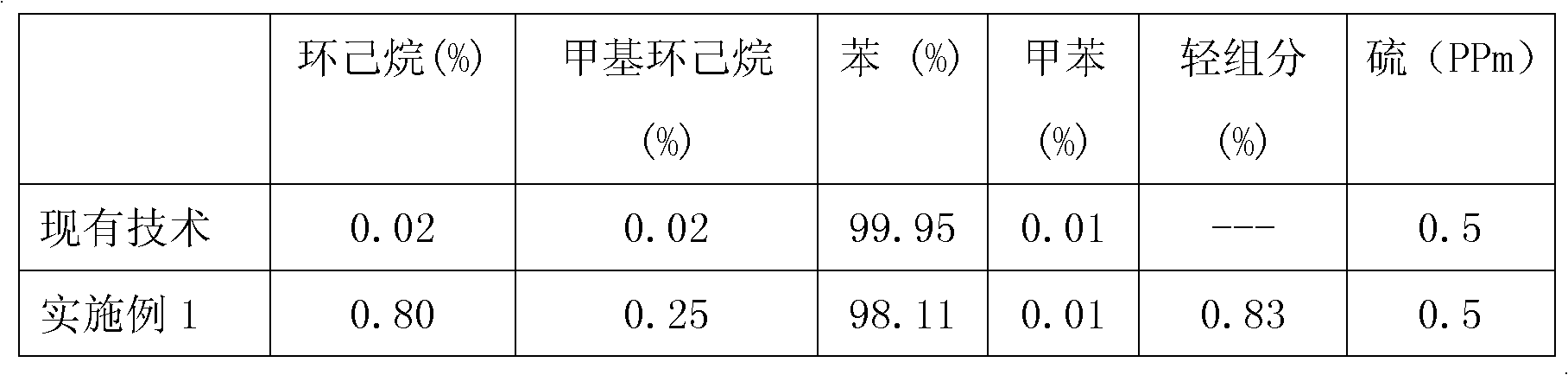

Embodiment 1

[0042] A crude benzene hydrogenation refining method, the raw material of this embodiment is 1 ton of crude benzene, the mass percentage of its components is benzene: 80.57% toluene: 12.49% xylene: 2.24% light component: 0.66% heavy component: 4.04%, including the following steps in order:

[0043] A. Crude benzene pretreatment: Coking crude benzene enters the tower from the middle of the pretreatment tower for distillation and separation. The pressure at the top of the tower is normal pressure, the temperature at the top of the tower is 80°C, and the temperature at the bottom of the tower is 165°C to remove heavy aromatics;

[0044] B. Crude benzene hydrogenation and stabilization part: the material after step A has a hydrogen-oil ratio of 400:1 and a volume space velocity of 0.5h -1 , temperature 195°C, pressure 2.0MPa, Ni-Mo catalyst, convert unsaturated compounds into saturated compounds; hydrogen oil ratio 400:1, volume space velocity 0.5h -1 , temperature 280°C, pressur...

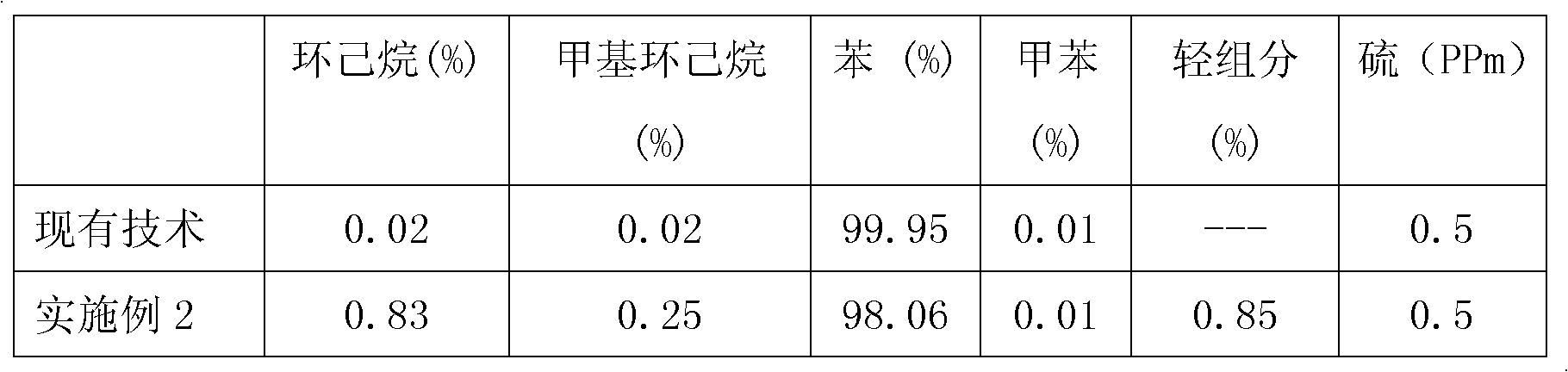

Embodiment 2

[0056] A method for preparing cyclohexanone by hydrogenating crude benzene. The raw material of this embodiment is 1.2 tons of crude benzene, and its component mass percentage is benzene: 80.57% toluene: 12.49% xylene: 2.24% light component: 0.66 % heavy component: 4.04%, including the following steps in turn:

[0057] A. Crude benzene pretreatment: Coking crude benzene enters the tower from the middle of the pretreatment tower for distillation and separation. The pressure at the top of the tower is normal pressure, the temperature at the top of the tower is 95°C, and the temperature at the bottom of the tower is 195°C to remove heavy aromatics;

[0058] B. Crude benzene hydrogenation and stabilization part: the material after step A has a hydrogen-oil ratio of 800:1 and a volume space velocity of 1.50h -1 , temperature 220°C, pressure 3.0MPa, Ni-Mo catalyst, convert unsaturated compounds into saturated compounds; hydrogen oil ratio 800:1, volume space velocity 1.5h -1 , temp...

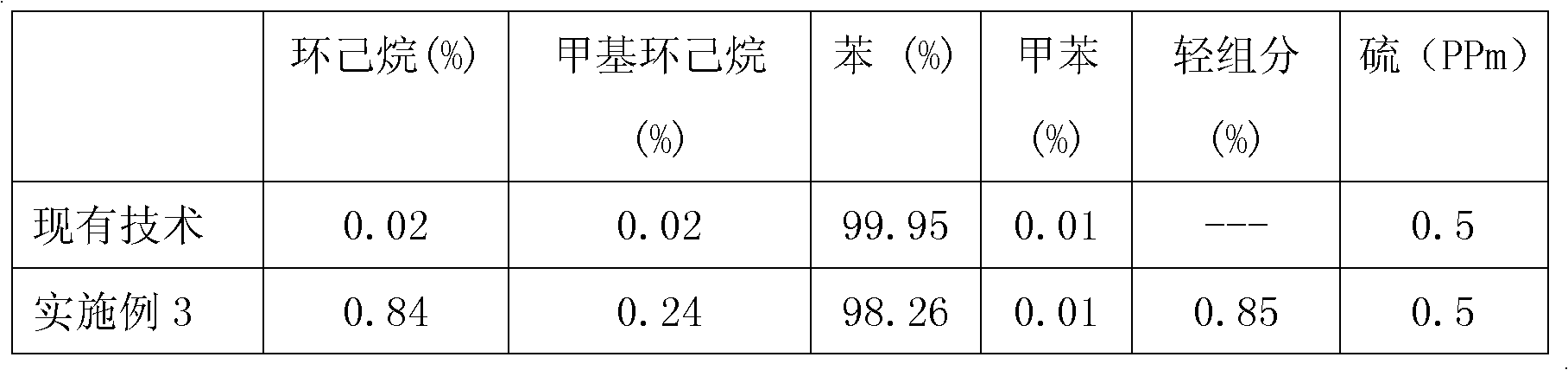

Embodiment 3

[0070] A method for preparing cyclohexanone by hydrogenation of crude benzene, the raw material of this embodiment is 1.5 tons of crude benzene, the mass percentage of its components is benzene: 80.57% toluene: 12.49% xylene: 2.24% light component: 0.66 % heavy component: 4.04%, including the following steps in turn:

[0071] A. Crude benzene pretreatment: Coking crude benzene enters the tower from the middle of the pretreatment tower for distillation and separation. The pressure at the top of the tower is normal pressure, the temperature at the top of the tower is 95°C, and the temperature at the bottom of the tower is 175°C to remove heavy aromatics;

[0072] B. Crude benzene hydrogenation and stabilization part: the material after step A has a hydrogen-oil ratio of 600:1 and a volume space velocity of 0.90h -1 , temperature 200°C, pressure 2.5MPa, Ni-Mo catalyst, convert unsaturated compounds into saturated compounds; hydrogen oil ratio 600:1, volume space velocity 0.9h -1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com