Preparation method of rubber/mesoporous molecular sieve nanocomposite

A nanocomposite material and mesoporous molecular sieve technology, applied in the field of nanocomposite materials, can solve problems such as the difficulty of combining inorganic nanoparticles, achieve simplified organic modification and nanocomposite processes, reduce the pressure of shortages and price increases, and provide excellent reinforcement effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

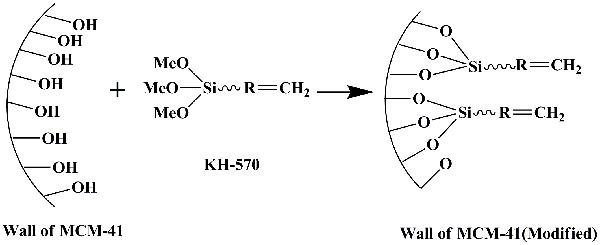

[0023] The preparation method of the rubber / mesoporous molecular sieve nanocomposite of the present invention comprises the following preparation steps and process conditions:

[0024] (1) Add mesoporous molecular sieve powder and modifier, and various conventional rubber compounding agents during the rubber mixing process, and mix evenly to obtain the mixed rubber.

[0025] (2) Vulcanize the above compounded rubber by a conventional rubber vulcanization method to obtain a rubber / mesoporous molecular sieve nanocomposite material.

[0026] The mass ratio of various raw materials in the present invention is: 100 parts of rubber, 0.5-20 parts of mesoporous molecular sieve powder, 0.5-10 parts of modifier, and other rubber compounding ingredients are determined according to the usual rubber formula. Among them: rubber includes one or more blends of natural rubber, various synthetic rubbers, and elastomers; modifiers include one or more of the following substances:

[0027] M...

Embodiment 1

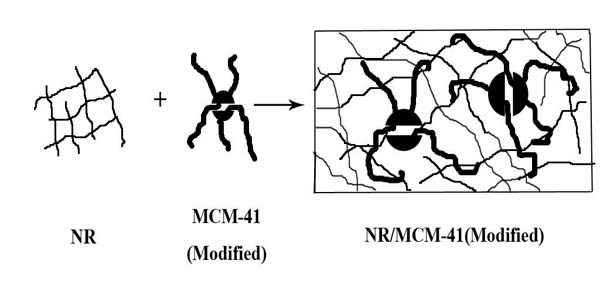

[0041] Choose natural rubber (NR), use molecular sieve MCM-41 (with holes) as filler, and use coupling agents KH-570, KH-550, Si-69, and NDZ-01 as modifiers. The formula is shown in Table 1. Mixing on the open mill, first add molecular sieve MCM-41 (with holes) and coupling agent KH-570, KH-550, Si-69, NDZ-01 four different modifiers, and then add other compounds agent, and finally add sulfur to obtain a rubber compound. The mixed rubber is vulcanized on a flat vulcanizer, the vulcanization temperature is 150°C, and the vulcanization time is determined according to the positive vulcanization time measured by the vulcanization meter.

[0042] Table 1

[0043]

[0044] The mechanical properties of NR / MCM-41 nanocomposite vulcanizates modified with different coupling agents are shown in Table 2. As can be seen from the table, the modulus, tensile strength and hardness of NR / MCM-41 modified with different coupling agents all show different degrees of improvement, among whi...

Embodiment 2

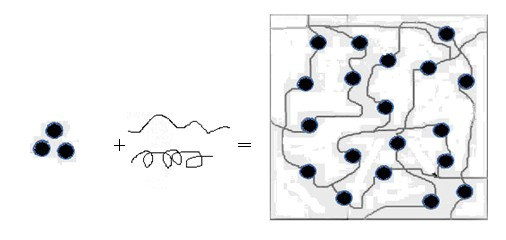

[0052] Select styrene-butadiene rubber and molecular sieve (with holes) (SBR / MCM-41, SBR / MCM-48, SBR / SBA-15), choose molecular sieves MCM-41 (with holes), MCM-48 (with holes), SBA- 15 (porous) was used as filler, and sodium dodecyl sulfate (SDS) was used as modifier. Formula (mass ratio): SBR 100, molecular sieve variable, stearic acid 2, zinc oxide 5, accelerator CZ 1.5, antioxidant 4010A 1.5, sulfur 1.5. After SBR is masticated, three different molecular sieves and modifier SDS are added respectively, and then other compounding agents are added, and finally sulfur is added to obtain a rubber compound. The mixed rubber is vulcanized on a flat vulcanizer at a vulcanization temperature of 160°C, and the vulcanization time is determined according to the positive vulcanization time measured by the vulcanizer.

[0053] Table 4 lists the mechanical properties of SBR filled with three different molecular sieves (MCM-41, MCM-48, SBA-15) without SDS modification and SDS modificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com