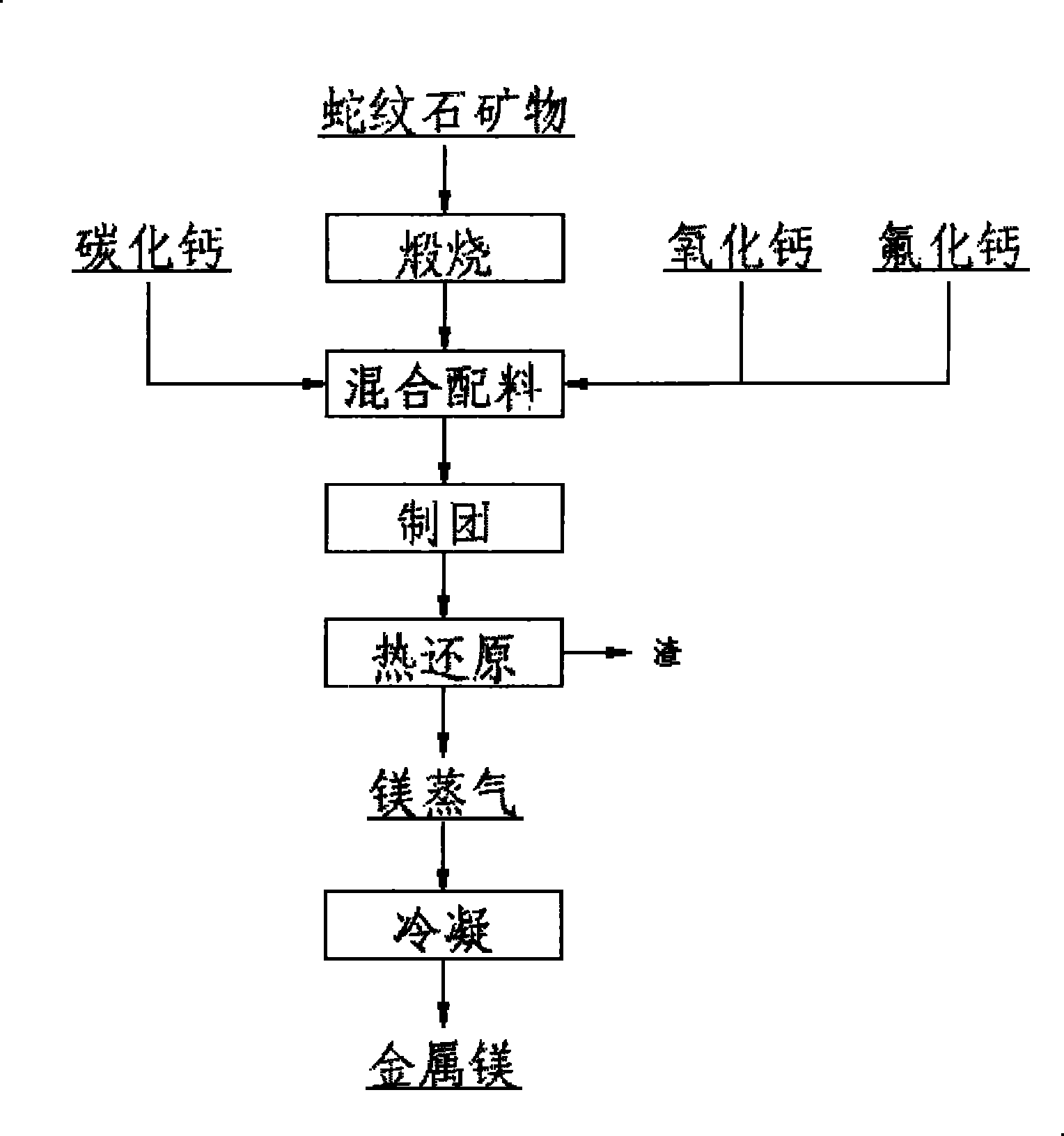

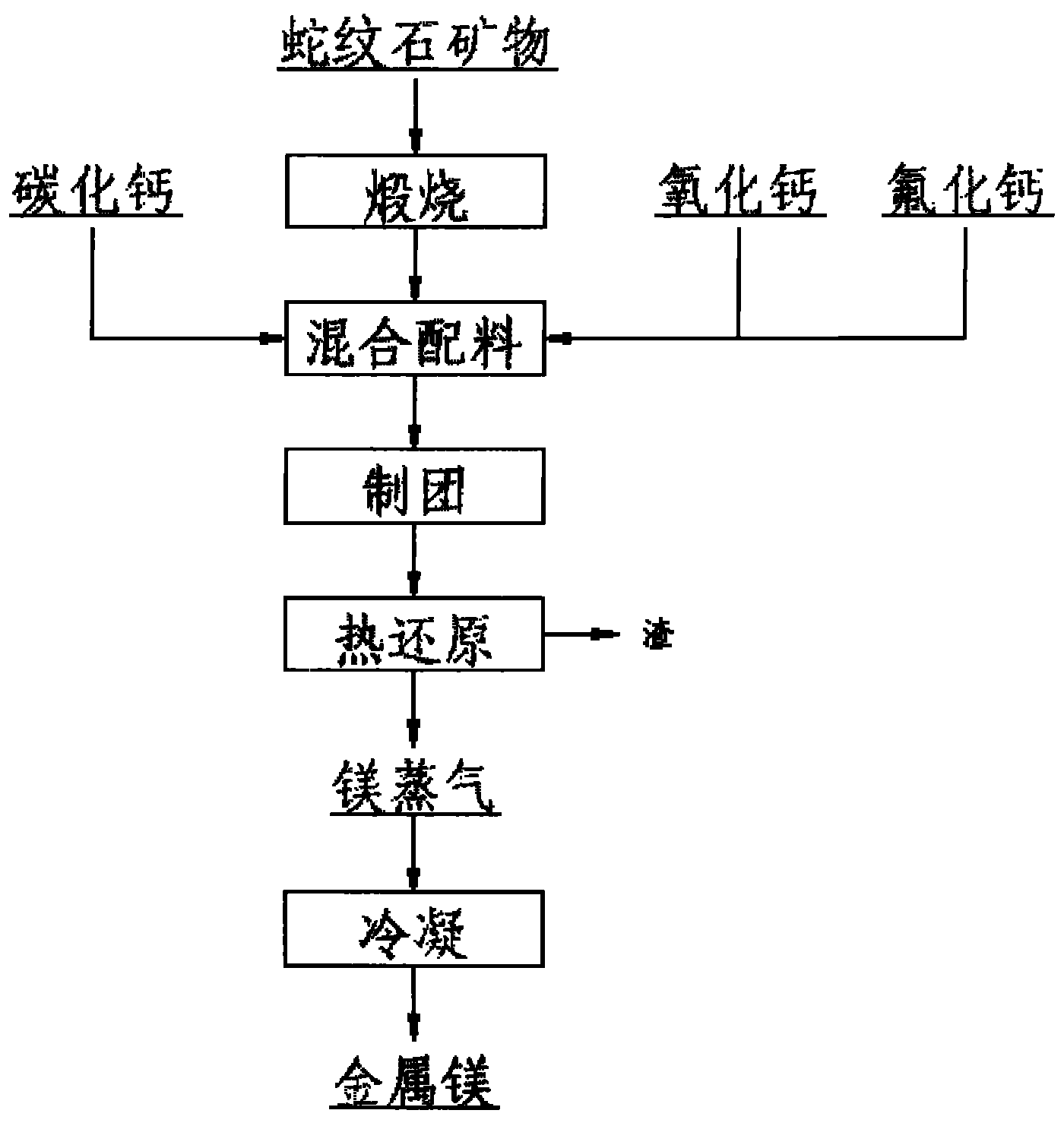

Process for preparing metal magnesium by normal pressure thermal reduction method

A reduction method and metal magnesium technology, applied in the field of non-ferrous metal smelting, can solve problems such as unsatisfactory, small production scale of magnesium plants, short service life of reduction tanks, etc., and achieve the effects of improving production efficiency, expanding production scale, and high utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Serpentine minerals with an MgO content of 43.6% were used as raw materials, which were added into a furnace, and the temperature was raised to 500° C. to remove crystal water to obtain a calcined product. According to the weight ratio of calcined product, reducing agent and auxiliary agent 30:24:7, add 5wt% calcium fluoride, mix evenly, and press under 50Mpa to form pellets with a particle size of about 30mm. Put the pellets into the furnace, raise the temperature to 1100°C, and reduce to obtain magnesium vapor. The magnesium vapor is condensed on the magnesium condenser at 200°C and collected to obtain metallic magnesium.

Embodiment 2

[0022] Example 2: Serpentine minerals with an MgO content of 43.6% were used as raw materials, put into a furnace, heated to 600° C. to remove crystal water, and calcined products were obtained. According to the weight ratio of calcined product, reducing agent and auxiliary agent 30:35:15, add 8wt% calcium fluoride, mix evenly, and press under 50Mpa to form pellets with a particle size of about 30mm. Put the pellets into the furnace, raise the temperature to 1150°C, and reduce to obtain magnesium vapor. The magnesium vapor is condensed on the magnesium condenser at 300°C and collected to obtain metallic magnesium.

Embodiment 3

[0023] Example 3: Serpentine minerals with an MgO content of 43.6% were used as raw materials, put into a furnace, heated to 750° C. to remove crystal water, and calcined products were obtained. According to the weight ratio of calcined product, reducing agent and auxiliary agent 30:50:20, add 10wt% calcium fluoride, mix evenly, and press under 50Mpa to form pellets with a particle size of about 30mm. Put the pellets into the furnace, raise the temperature to 1200°C, and reduce to obtain magnesium vapor. The magnesium vapor is condensed on the magnesium condenser at 500°C and collected to obtain metallic magnesium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com