Activated metal salt flocculant and process for producing same

A technology of active metals and manufacturing methods, applied in separation methods, chemical instruments and methods, metallurgical wastewater treatment, etc., can solve the problems of anaerobic bacteria death, poor ability to remove dissolved organic matter, and inability to use anaerobic bacteria treatment, etc. , to achieve strong cohesion and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The following apparatus was used as an electrolysis apparatus.

[0085] An electrolytic cell was used in which platinum wires were installed as electrodes (diameter 0.3 mm, length 12.5 mm (effective length 40 mm), distance between electrodes 13 mm) in a cylindrical glass container with an inner diameter of 18 mm and a height of 50 mm.

[0086] The electrolytic treatment conditions are as follows:

[0087] Applied voltage DC 45V (below)

[0088] Current value 30mA (constant current control)

[0089] Water temperature 23°C

[0090] Processing time 90 minutes

[0091] Electricity 16 coulomb / g

[0092] Add 10mL polyaluminum chloride (PAC: [Al 2 (OH) n Cl 16-n ] m ) (n=1 to 5, m≦10) (manufactured by Hokkaido Soda Co., Ltd.) was energized and electrolytically treated to obtain activated PAC as an activated metal salt flocculant.

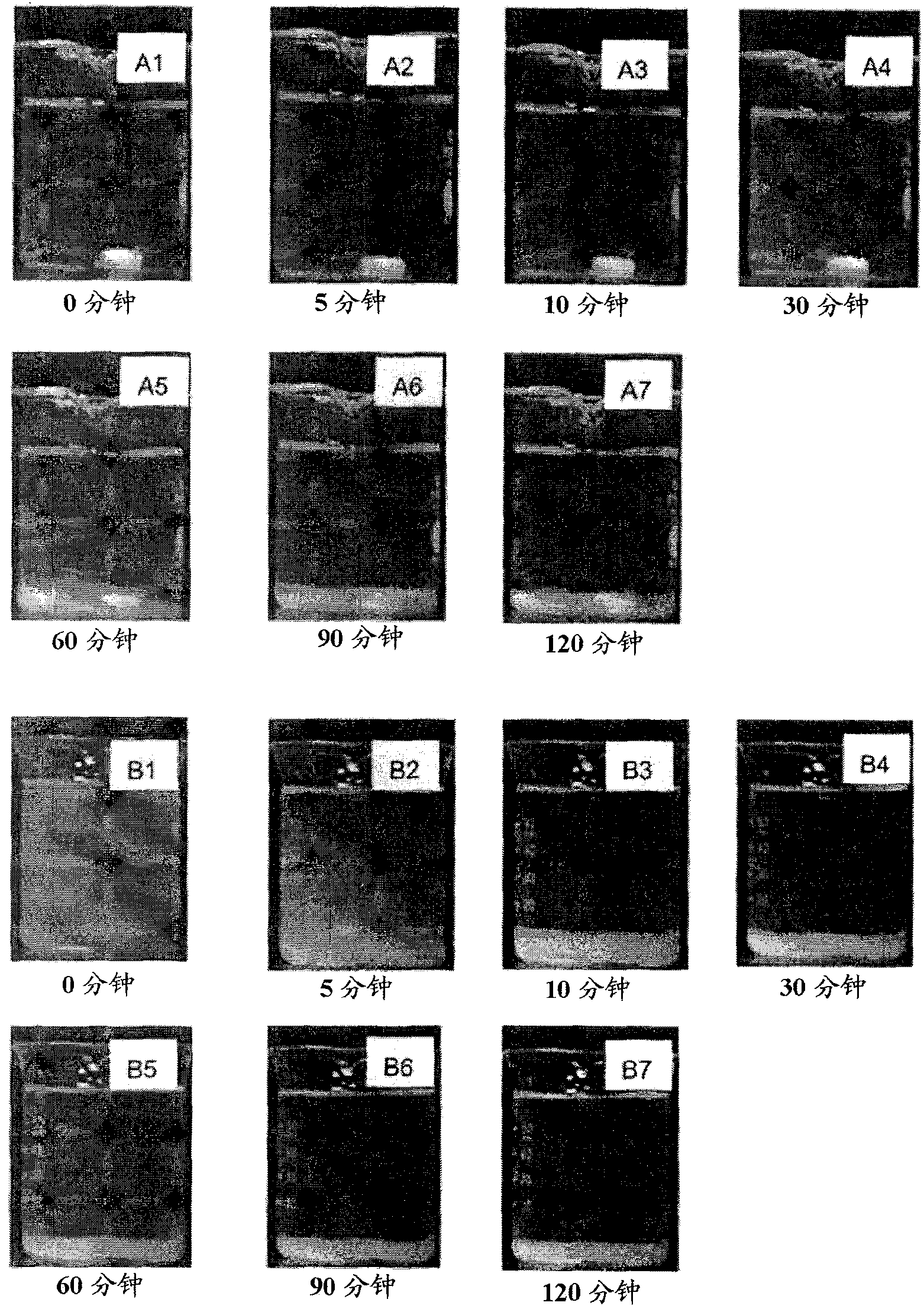

[0093] 1 mL of the above-obtained activated PAC was mixed with 1 mL of water as a sample. In addition, the PAC which was not electrolyzed...

Embodiment 2

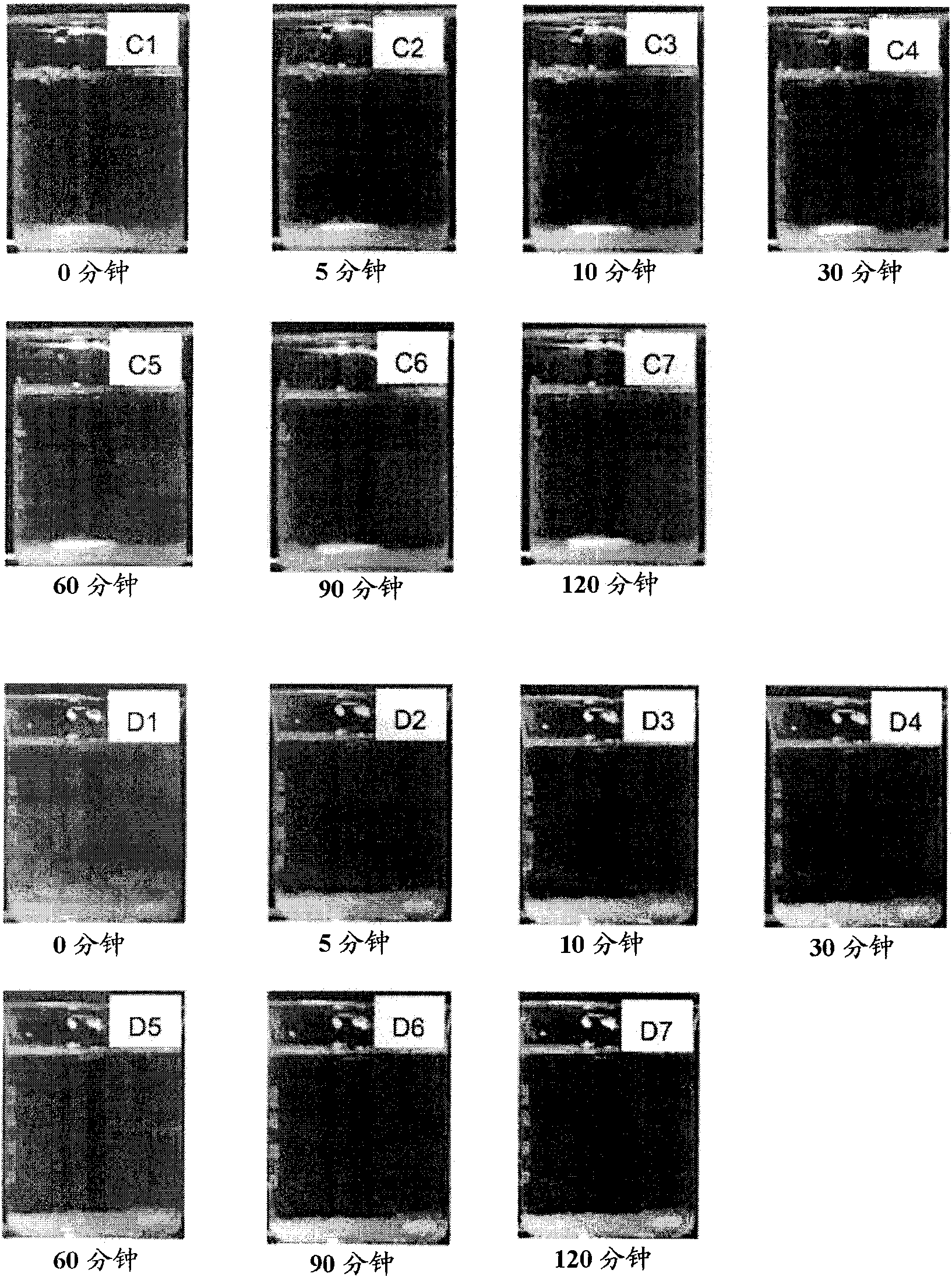

[0099] The same test as in Example 1 was carried out using an aqueous solution of albumin (concentration: 50 μM) instead of the aqueous solution of globulin. In addition, the same experiment was performed on PAC which was not electrolytically treated, and this was defined as Comparative Example 2. The result is as figure 2 shown. exist figure 2 Among them, C1~C7 are the results of Comparative Example 2, and D1~D7 are the results of Example 2, respectively showing the results after standing for 0 minutes, 5 minutes, 10 minutes, 30 minutes, 60 minutes, 90 minutes and 120 minutes. result.

[0100] In Comparative Example 2, the PSI sample was added to the albumin aqueous solution in the beaker and stirred, and immediately became cloudy, but precipitates aggregated immediately after standing, and the solution became transparent (C1). Thereafter, no change in the aggregates at the bottom of the beaker was observed, but 30 minutes later, aggregates floated on the water surface....

Embodiment 3

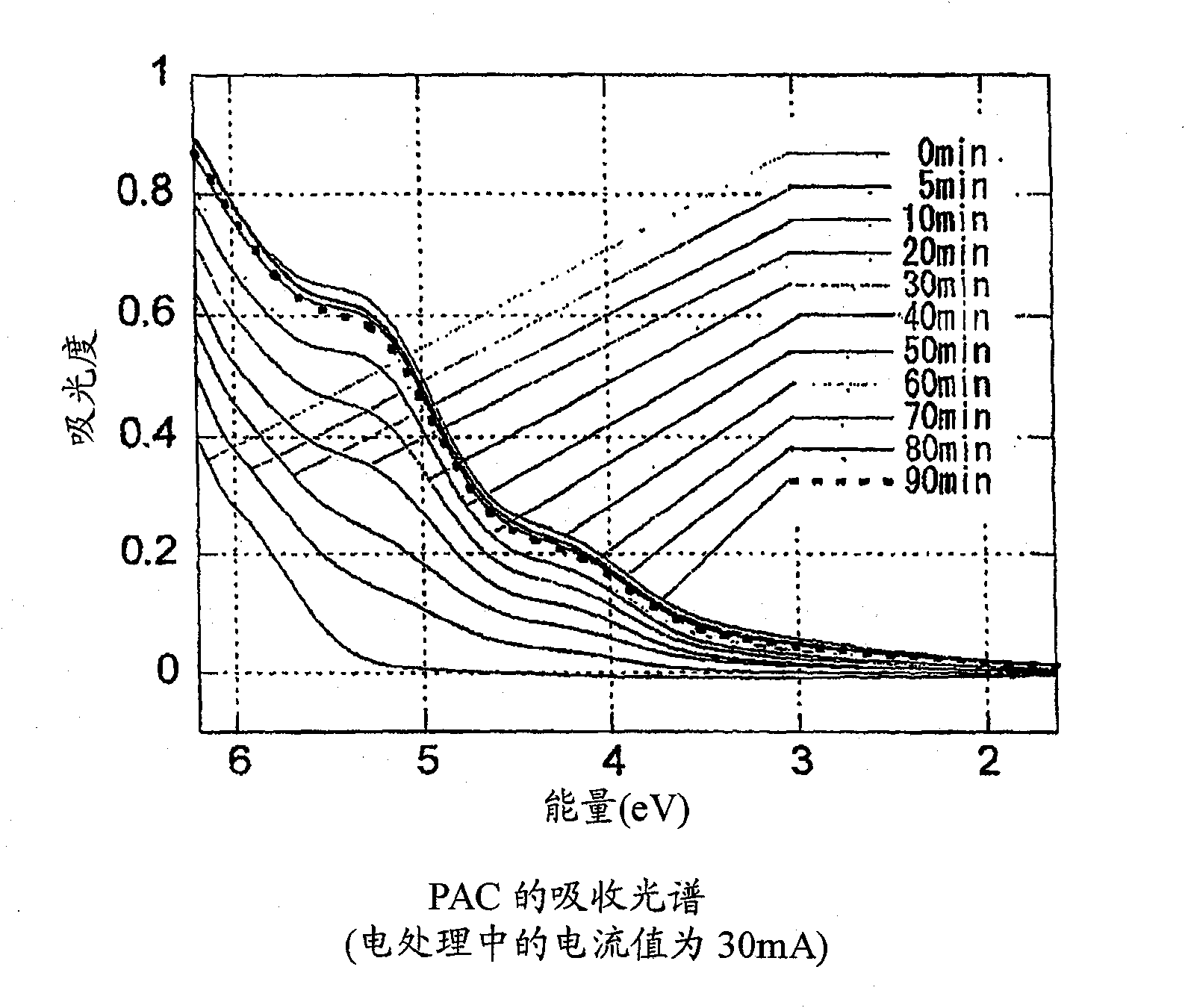

[0108] Investigate the relationship between electrolytic processing and absorption spectra.

[0109]Same as Example 1, carry out electrolytic treatment to polyaluminum chloride, before electrolytic treatment starts, after electrolytic treatment starts 5 minutes, after electrolytic treatment starts 10 minutes, and afterwards every 10 minutes take sample, until 90 minutes, with automatic The absorption spectrum was measured with a recording spectrophotometer (manufactured by Hitachi, Ltd.: U-3500). The result is as image 3 shown.

[0110] like image 3 It can be seen that, if electrolytic treatment is performed, the absorbance increases in the entire ultraviolet-visible light region, but as the electrolytic treatment time increases, light absorption bands appear around 5.2-5.4eV and 4.0-4.2eV.

[0111] Subtract the initial absorption spectrum from the absorption spectrum of PAC treated at each treatment time above to obtain the light absorption increase component changed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com