Method for preparing sustained-release carbon material by using low molecular weight polylactic acid

A slow-release carbon material and low molecular weight technology, applied in the field of water treatment, to achieve strong operability, low cost, and overcome microbial nutritional imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

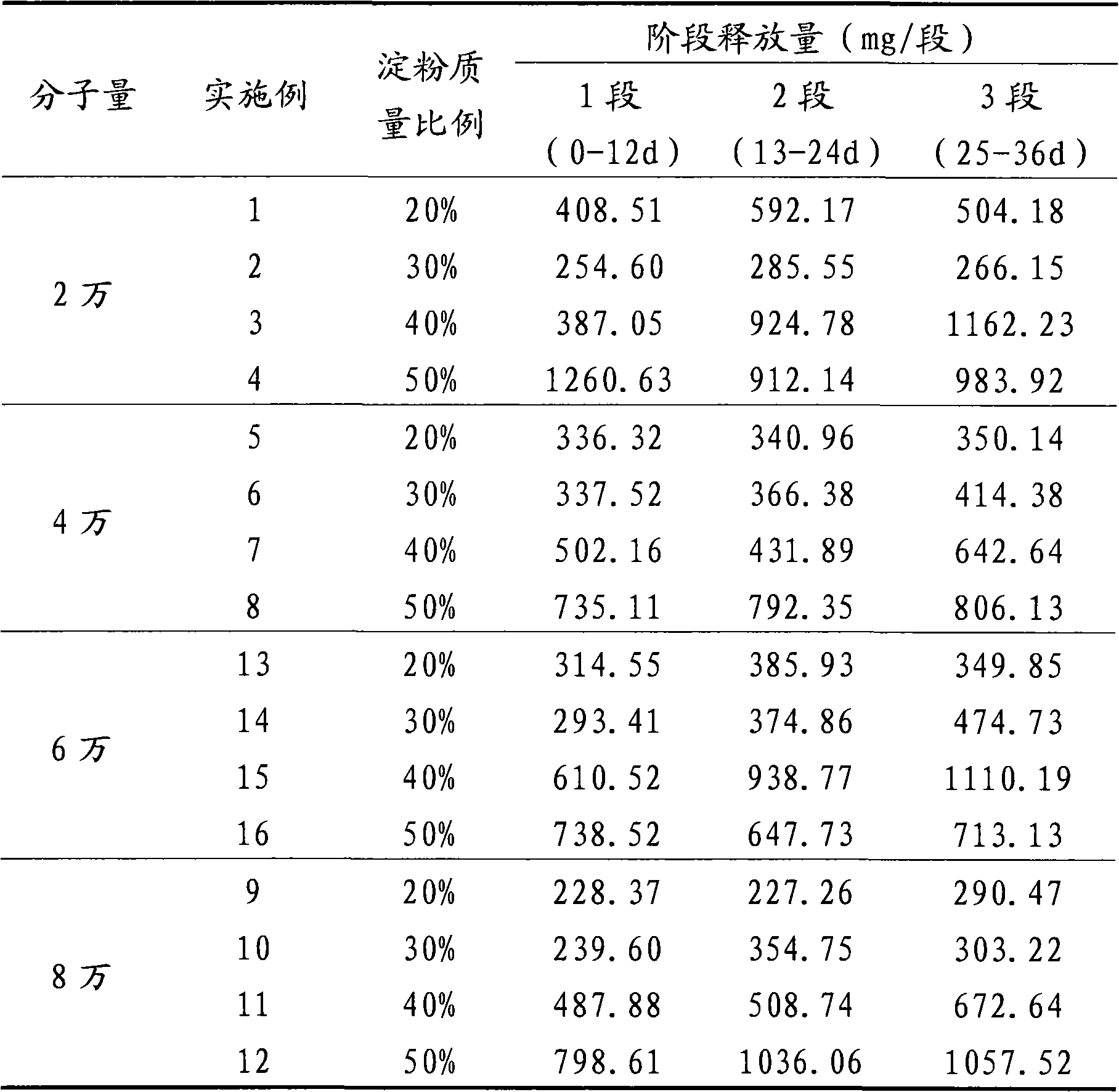

[0022] Example 1: Weigh 20g per portion, select polylactic acid with a molecular weight of 20,000, polylactic acid and starch in a mass ratio of 8:2, pulverize in a high-speed pulverizer, stir evenly, and slowly add to the temperature at a constant speed In an injection molding machine at 100-180°C, extrude into a cylinder with a diameter of 0.3-0.8 cm, and after cooling at room temperature, a short cylinder with a length of 1.0-4.0 cm is formed.

Embodiment 2

[0023] Example 2: Weigh 20g per portion, select polylactic acid with a molecular weight of 20,000, polylactic acid and starch in a mass ratio of 7:3, pulverize in a high-speed pulverizer, stir evenly, and add slowly and uniformly to the temperature. In an injection molding machine at 100-180°C, extrude into a cylinder with a diameter of 0.3-0.8 cm, and after cooling at room temperature, a short cylinder with a length of 1.0-4.0 cm is made.

Embodiment 3

[0024] Example 3: Weigh 20g per portion, select polylactic acid with a molecular weight of 20,000, polylactic acid and starch in a mass ratio of 6:4, pulverize in a high-speed pulverizer, stir evenly, and slowly add to the temperature at a constant rate In an injection molding machine at 100-180°C, extrude into a cylinder with a diameter of 0.3-0.8 cm, and after cooling at room temperature, a short cylinder with a length of 1.0-4.0 cm is made.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com