Method for realizing SBR nitrosation-denitrosation at low temperature by optimally controlling aeration time

An aeration and low temperature technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve the effect of saving external carbon sources and reducing aeration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、15

[0038] Example 1. Using the SBR method at 15°C to realize nitrosation-denitritation of landfill leachate

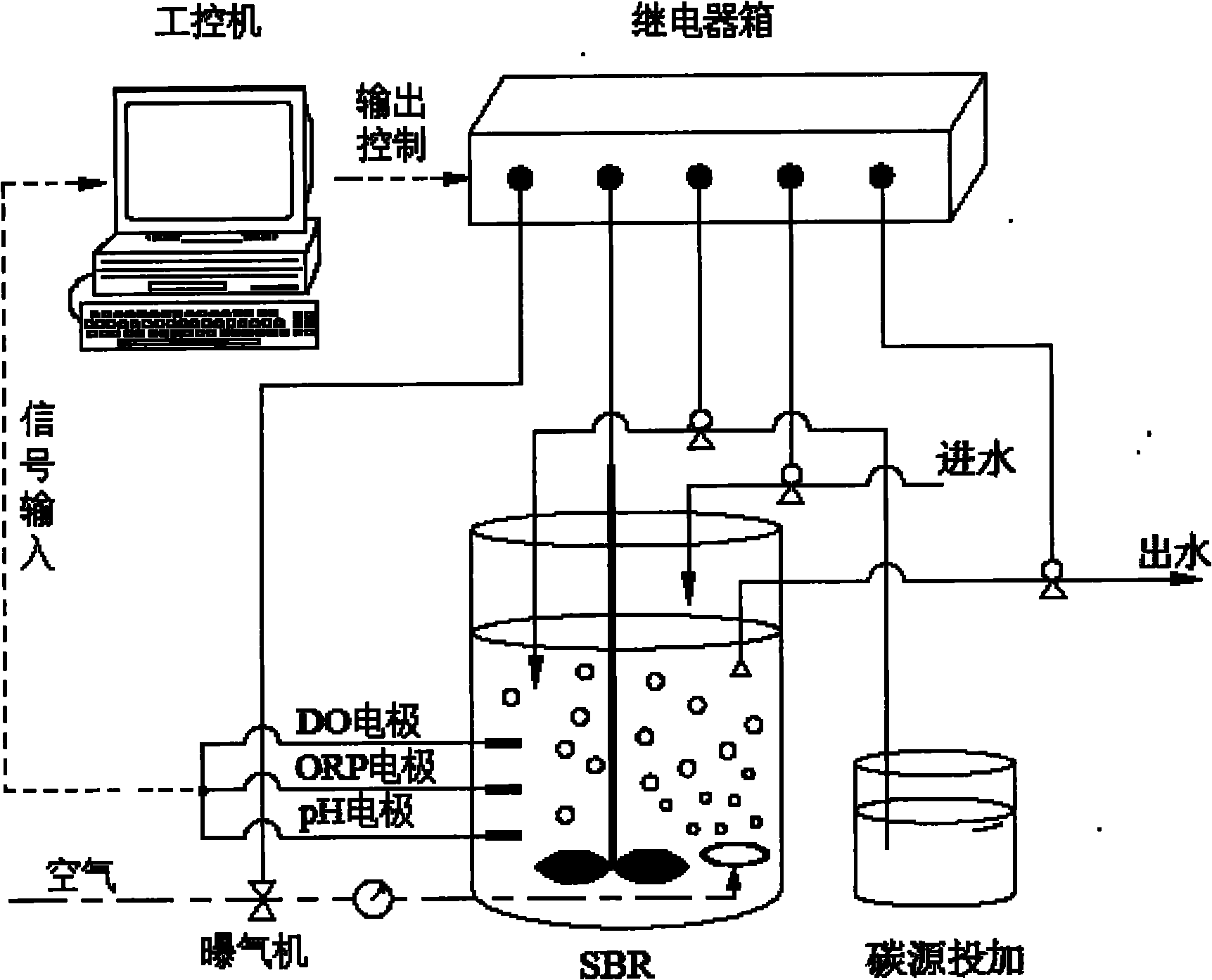

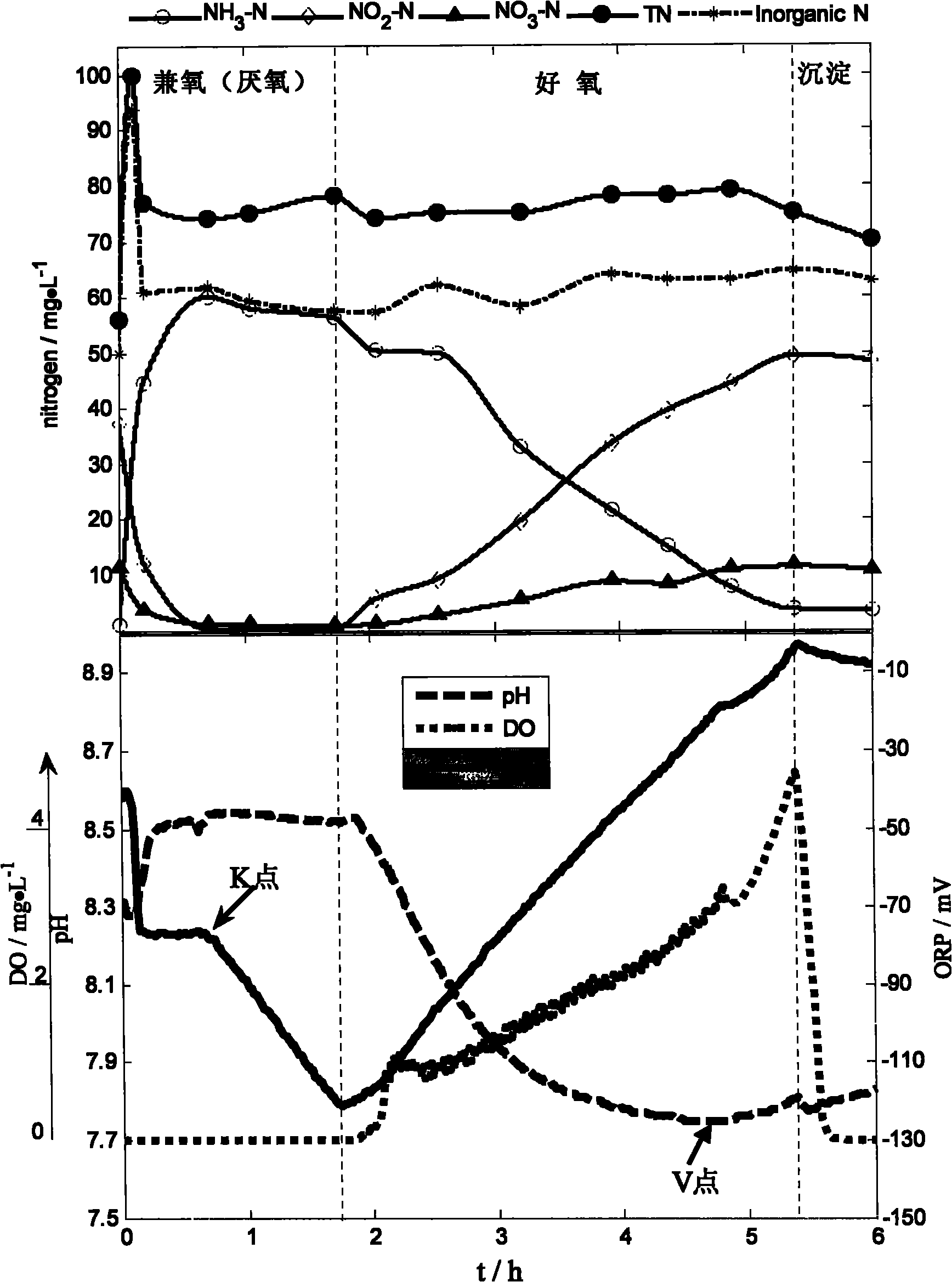

[0039] A landfill leachate is treated with a real-time control SBR system (see Table 1 for water quality indicators), and the reactor temperature is controlled at 15±0.5°C. This embodiment adopts the control mode a) of the present invention to realize nitrosation-denitritation. In the cycle (the cycle process includes 5 units, water inflow-facultative (anaerobic)-aerobic-precipitation-water outflow) nitrogen conversion and corresponding real-time curves such as figure 2 shown. NH in the reactor system 3 -N and TN jump with the water inflow, and the external carbon source is added to the system in the facultative stage, so that the NO produced by the aerobic unit in the previous cycle 2 -N and NO 3 -N is all restored to N 2 . Then the system enters the aerobic unit, and uses the appropriate aeration flow rate (about 3.5L / min, calculated and determined according to fo...

Embodiment 1

[0040] In embodiment 1, the SBR circulates the aerobic unit in each round, calculates according to the continuous monitoring value of ORP read by the computer, to judge whether the system needs to supplement the external carbon source (if dORP / dt2 ORP / dt 2 = 0, stop supplementing the carbon source, that is, figure 2 Stop replenishment when the K point in the middle). The aerobic unit calculates dpH / dt based on the pH continuous monitoring value read by the computer, and judges that a local minimum point ("ammonia valley point") appears on the real-time pH curve according to the change of dpH / dt from a negative value to a positive value, and uses this The point is the end of the time of the unit, so that the aeration is stopped in time to prevent the nitrous nitrogen from being further oxidized into nitrate nitrogen. The concentration and removal rate of influent and effluent pollutants are shown in Table 1.

[0041] Table 1. Running results of landfill leachate nitrification...

Embodiment 2、15

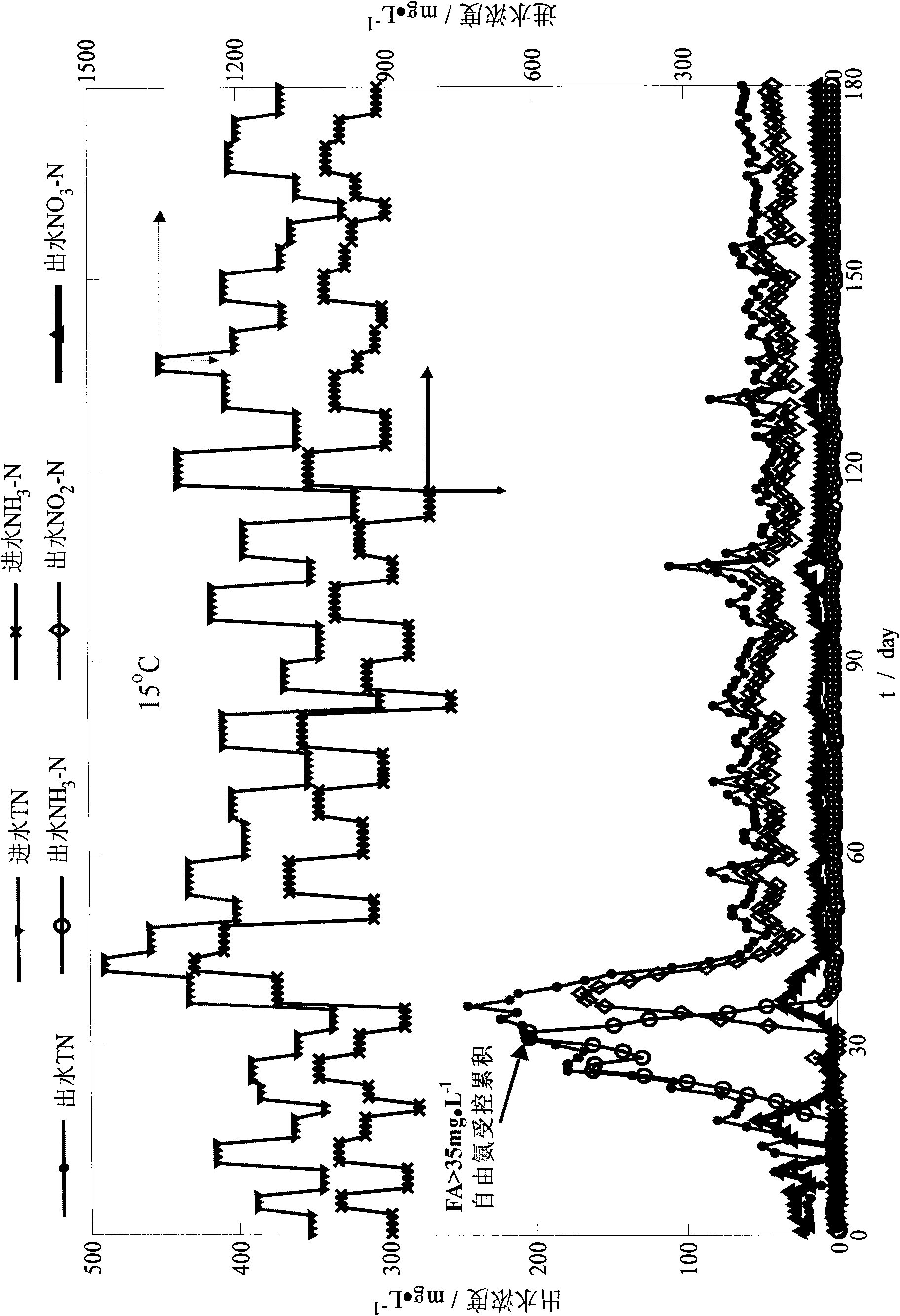

[0044] Example 2. Using SBR method at 15°C to realize nitrosation-denitritation of aquaculture wastewater

[0045] The real-time control SBR system is used to treat an intensive aquaculture wastewater (see Table 2 for the water quality index), and the temperature of the reactor is controlled at 15±0.5°C. denitrosation transformation. Concentrations of nitrogen pollutants in and out of water such as image 3 shown. 18 days before the operation of the reactor, the NH 3 -N and NO 2 -N is maintained at a low concentration level, while NO 3 -N accounts for more than 80% of TN. From the 19th day to the 32nd day, the aeration flow rate was reduced from 3.0L / min to 0.3L / min, and the NH in the system 3 -N gradually increased, while NO 3 -N rapidly decreased to 0mg / L. When the free ammonia concentration in the system rises to about 36.3mg / L (NH 3 -N≈205mg / L; pH=8.8), immediately restore the aeration rate to 3.0L / min for continuous aeration. NH 3 -N decreased to less than 5 mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com