Nanometer apatite phosphate fertilizer and preparation method thereof

An apatite and nanotechnology, which is applied in the field of nano-apatite phosphate fertilizer and its preparation, can solve the problems of not being able to realize and reduce soil fixation well at the same time, and achieve the effect of reducing the fixation of soil to phosphorus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Prepare 0.835 mol / L Ca(NO 3 ) 2 and 0.5 mol / L (NH 4 ) 2 HPO 4 solution, the pH value is adjusted to 11 with 0.1-1 mol / L ammonia water, and the molar ratio of Ca and P is 1.67, and (NH 4 ) 2 HPO 4 The solution was slowly added dropwise to the Ca(NO 3 ) 2 The solution was stirred with a magnetic stirrer at the same time, and the obtained precipitate was transferred to a tripod flask. After shaking in a horizontal shaker for 12 h, the sample was dried at 110 °C, and finally ground with an agate mortar.

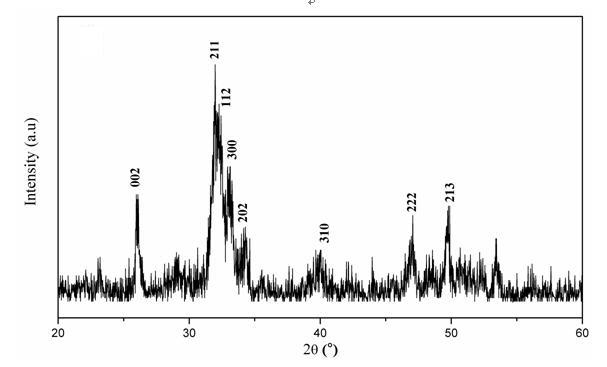

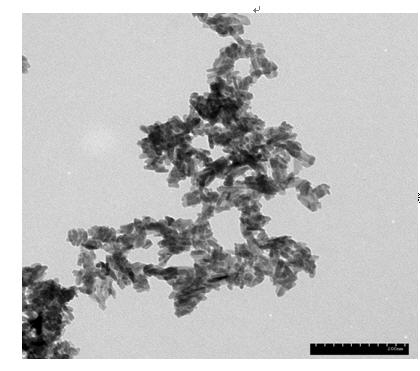

[0039] The nano-apatite phosphate fertilizer that makes, its X-ray diffractogram and transmission electron microscope photograph are respectively as follows figure 1 and figure 2 shown. Depend on figure 1 It can be seen that the nano-apatite phosphate fertilizer has broad diffraction peaks at 2θ values of 26°, 32°, 34°, 40°, 47° and 50° on the X-ray diffraction pattern. Depend on figure 2 It can be seen that the nano-apatite phosphate fertilizer includes n...

Embodiment 2

[0042] Prepare 1.67 mol / L Ca(NO 3 ) 2and 1 mol / L (NH 4 ) 2 HPO 4 solution, the pH value is adjusted to 11 with 0.1-1 mol / L ammonia water, and the molar ratio of Ca and P is 1.67, and (NH 4 ) 2 HPO 4 The solution was slowly added dropwise to the Ca(NO 3 ) 2 The solution was stirred with a magnetic stirrer at the same time, and the obtained precipitate was transferred to a tripod flask. After shaking in a horizontal shaker for 12 h, the sample was dried at 110 °C, and finally ground with an agate mortar.

Embodiment 3

[0044] Prepare 0.835 mol / L Ca(NO 3 ) 2 and 0.5 mol / L Ca(H 2 PO 4 ) 2 solution, the pH value is adjusted to 11 with 0.1-1 mol / L ammonia water, and the molar ratio of Ca and P is 1.67, and Ca(H 2 PO 4 ) 2 The solution was slowly added dropwise to the Ca(NO 3 ) 2 The solution was stirred with a magnetic stirrer at the same time, and the obtained precipitate was transferred to a tripod flask. After shaking in a horizontal shaker for 12 h, the sample was dried at 110 °C, and finally ground with an agate mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com