Method and electrolytic oxidation device for detecting film layer on surface of metal

A metal surface, electrolytic oxidation technology, applied in measuring devices, electromagnetic measuring devices, measuring electrical variables, etc., to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

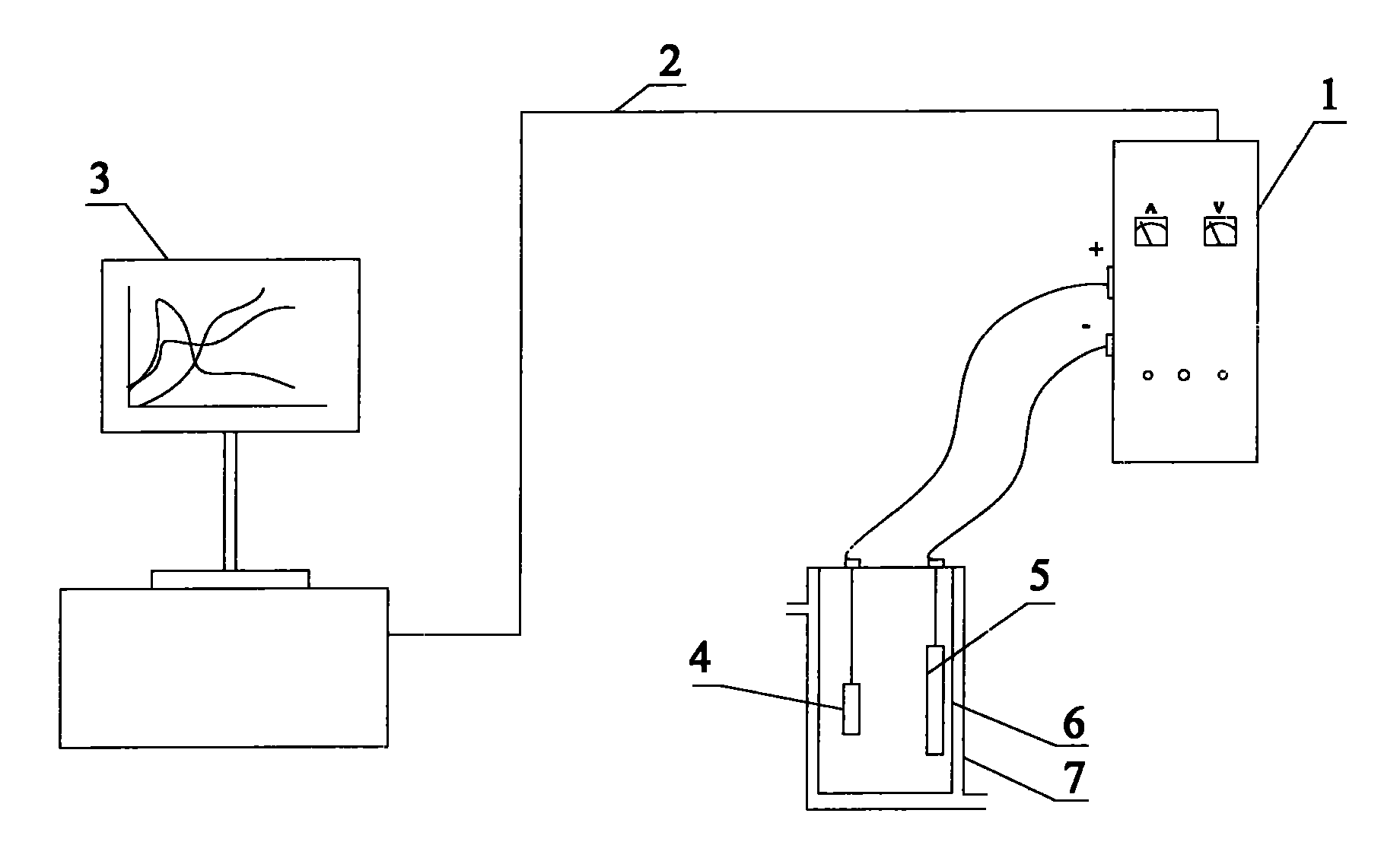

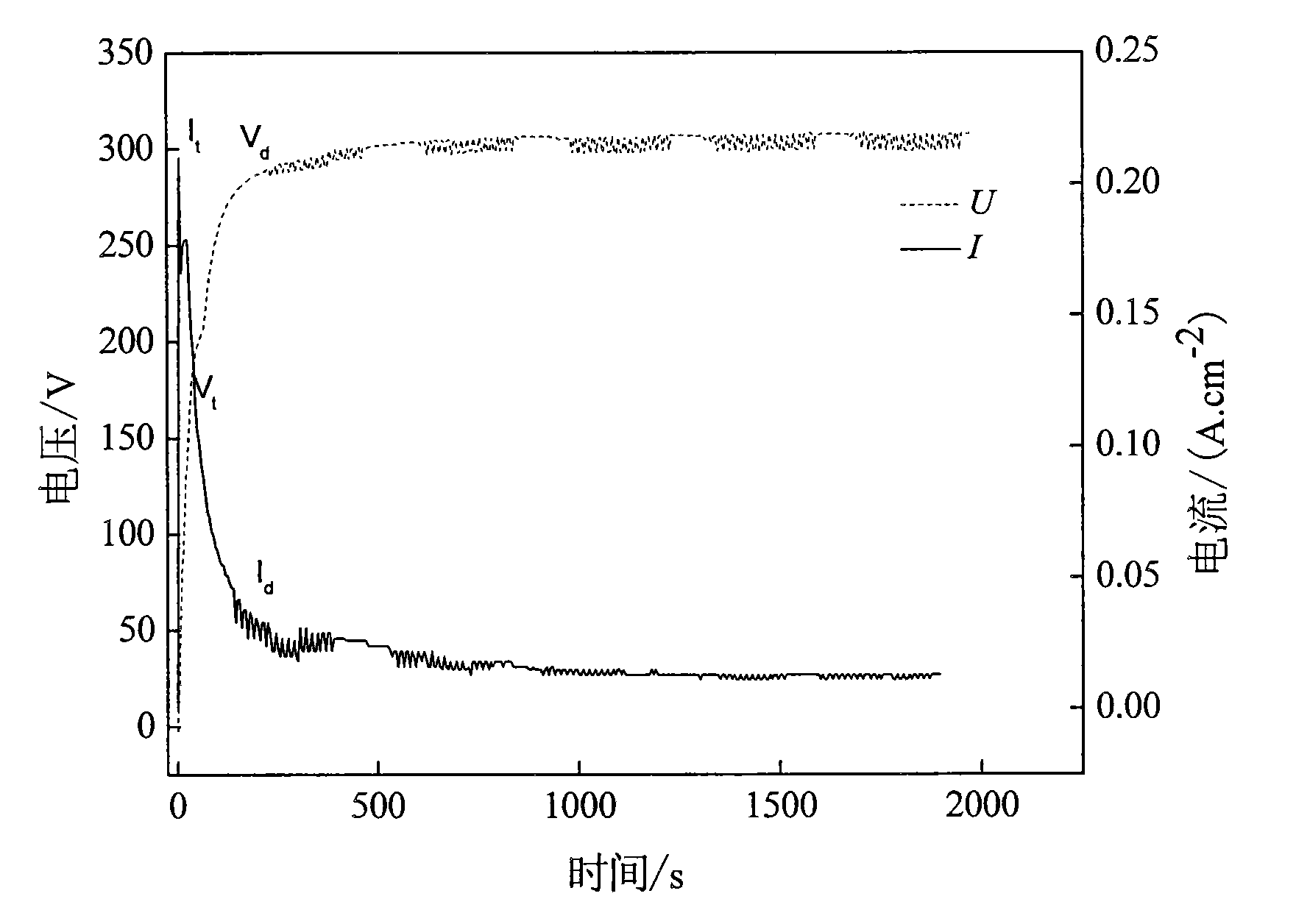

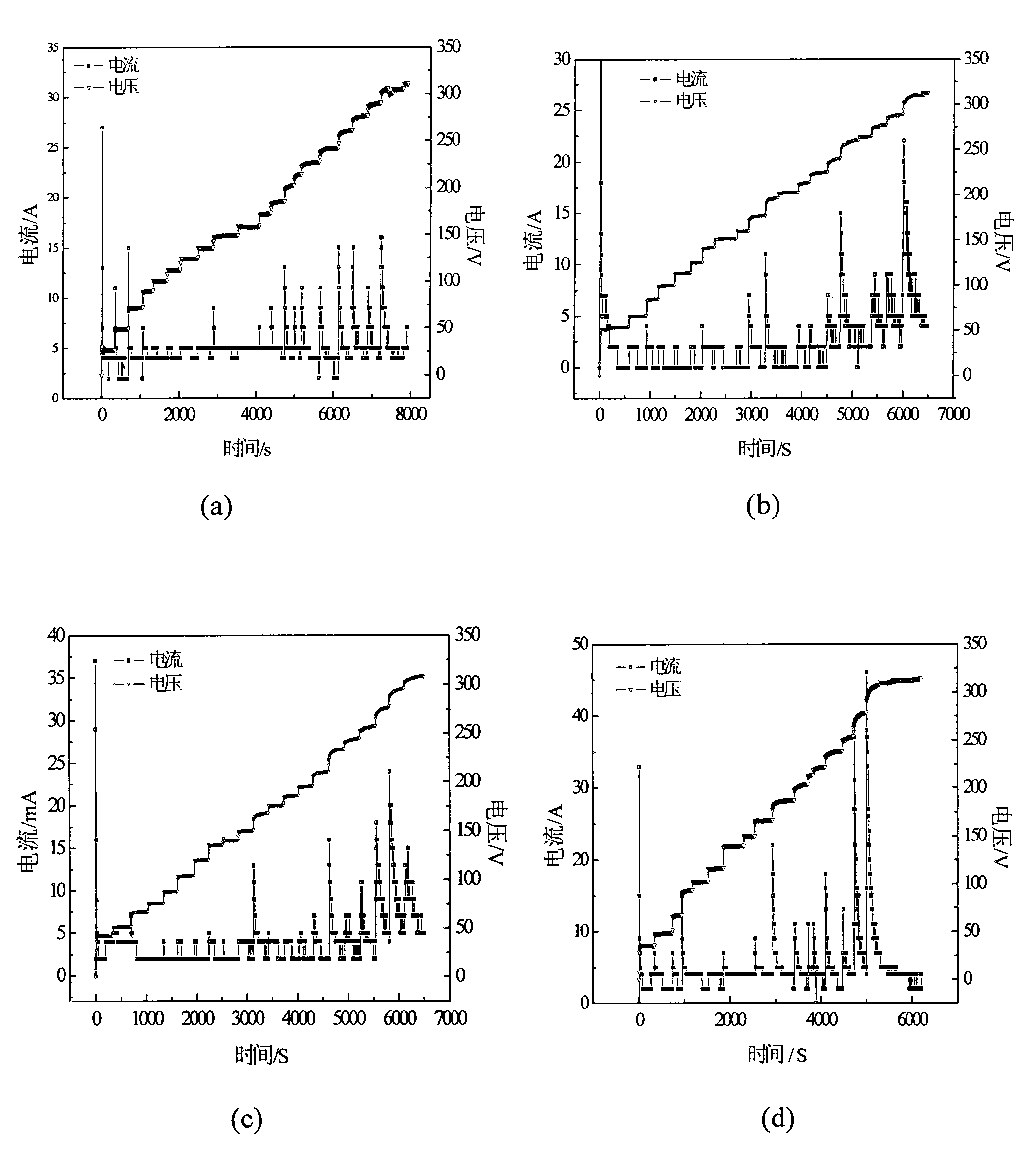

[0040]Plasma electrolytic oxidation detects the film thickness of magnesium metal samples coated with ceramic film on the surface, and the plasma electrolytic oxidation device includes three parts: DC power supply 1, data acquisition and processing system 3 and plasma electrolytic oxidation tank 6; the output current of DC power supply 1 is 0~2.5A, the voltage output is 0~700V; the positive pole of the power supply is connected to the sample 4 to be tested as the anode, the negative pole of the power supply is connected to the stainless steel plate auxiliary electrode 5 as the cathode, and the output current and voltage signals of the DC power supply 1 pass through the data The line 2 is input into the computer data acquisition system 3; the sample to be tested 4 and the auxiliary electrode 5 are placed in the plasma electrolytic oxidation tank 6, and the plasma electrolytic oxidation tank 6 has a circulating water cooling jacket 7, and the function of the cooling jacket is to k...

Embodiment 2

[0060] Plasma electrolytic oxidation detection surface corrosion resistance of aluminum metal surface coated with ceramic film, plasma electrolytic oxidation device, including DC power supply 1, data acquisition and processing system 3 and plasma electrolytic oxidation tank 6 three parts; the output current of DC power supply 1 is 0~2.5A, the voltage output is 0~700V; the positive pole of the power supply is connected to the sample 4 to be tested as the anode, the negative pole of the power supply is connected to the stainless steel plate auxiliary electrode 5 as the cathode, and the output current and voltage signals of the DC power supply 1 pass through the data The line 2 is input into the computer data acquisition system 3; the sample to be tested 4 and the auxiliary electrode 5 are all placed in the plasma electrolytic oxidation tank 6, and the plasma electrolytic oxidation tank 6 has a circulating water cooling jacket 7, and the circulating cooling water jacket is used for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com