Semiconductor structure for increasing integration density of high-voltage integrated circuit device and manufacturing method

A high-voltage integrated circuit, integration density technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, circuits, etc., can solve problems such as poor clamping, reduce processing time, improve the controllability of epitaxy quality, and reduce processing temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

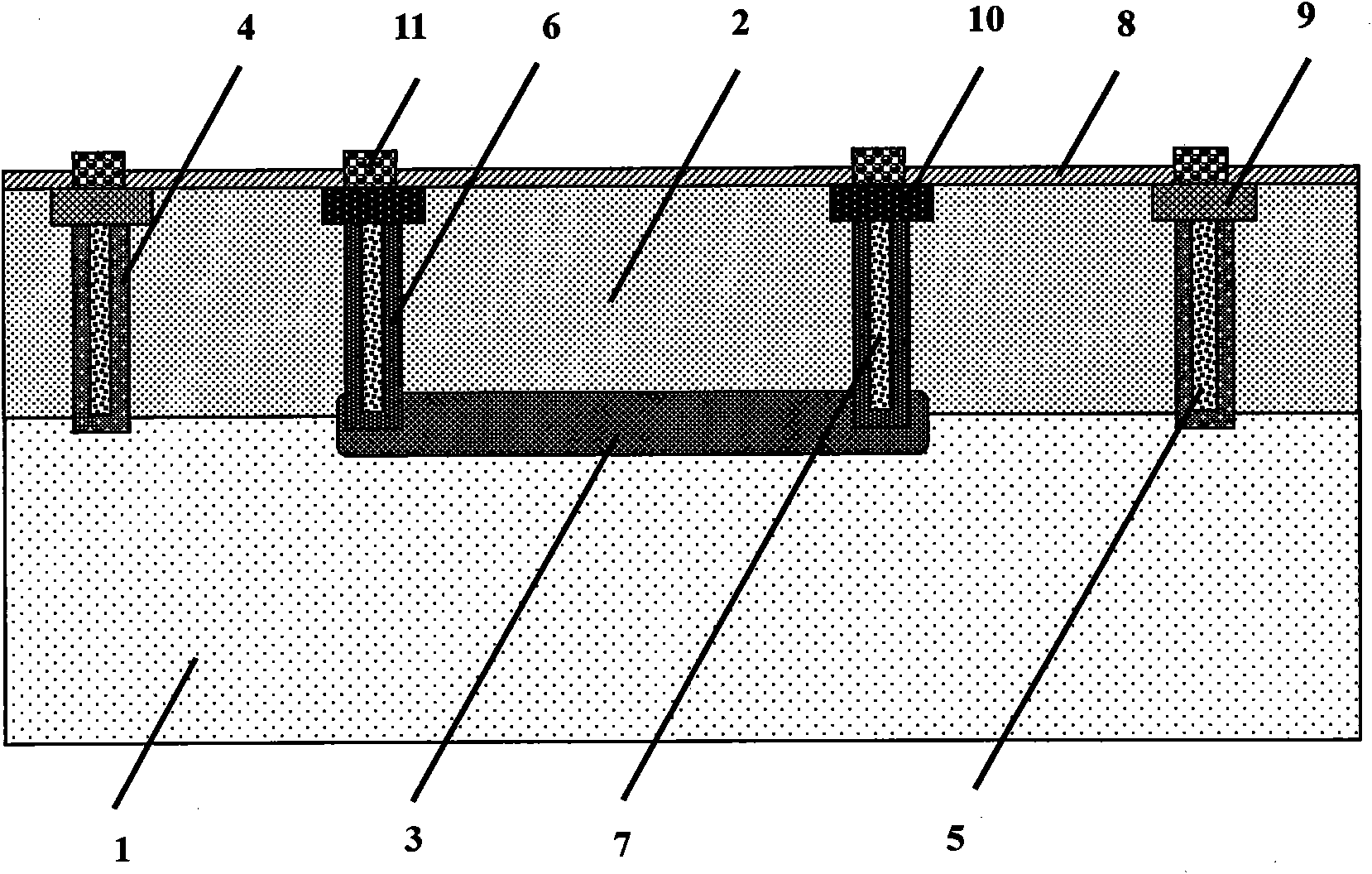

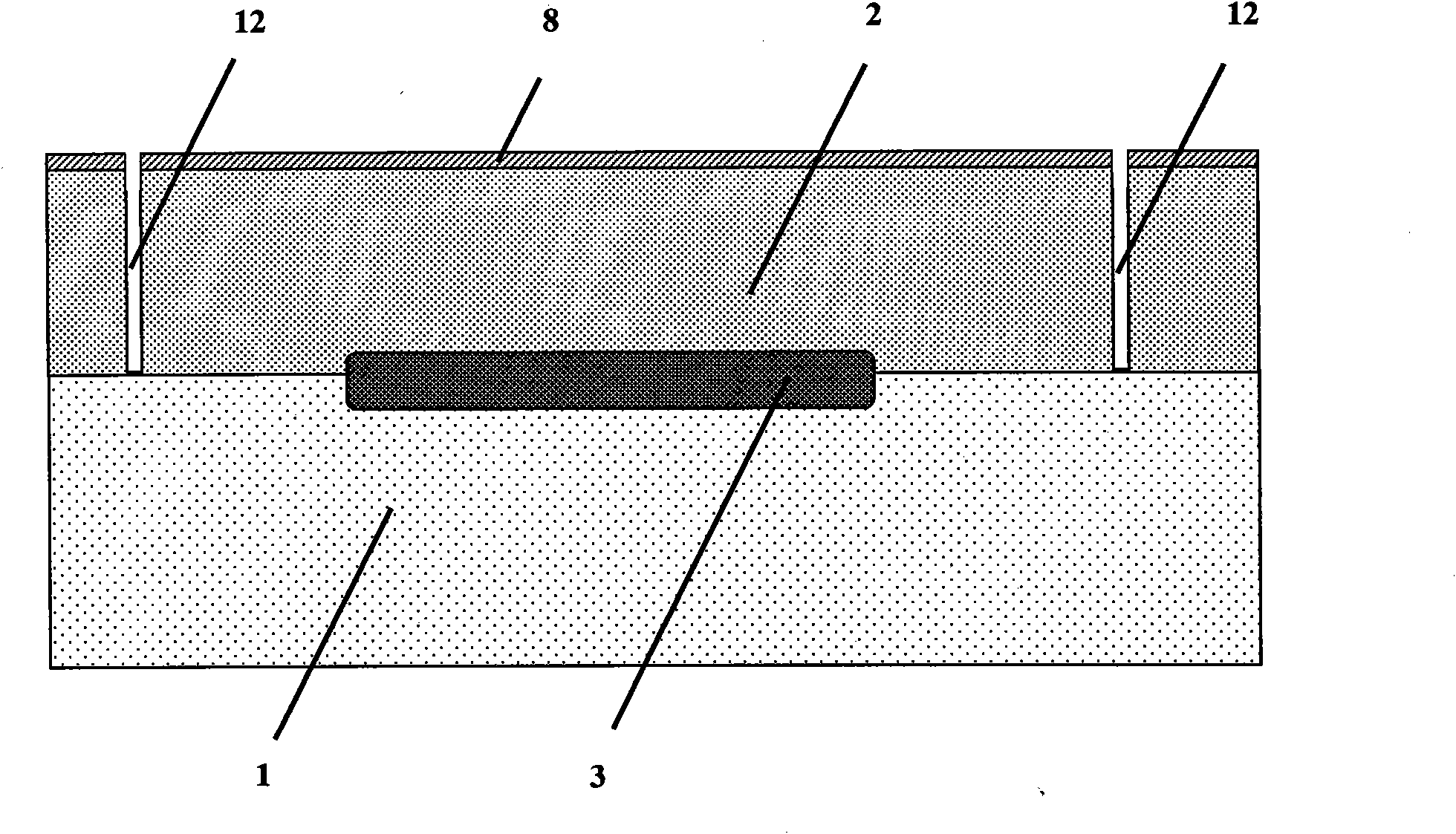

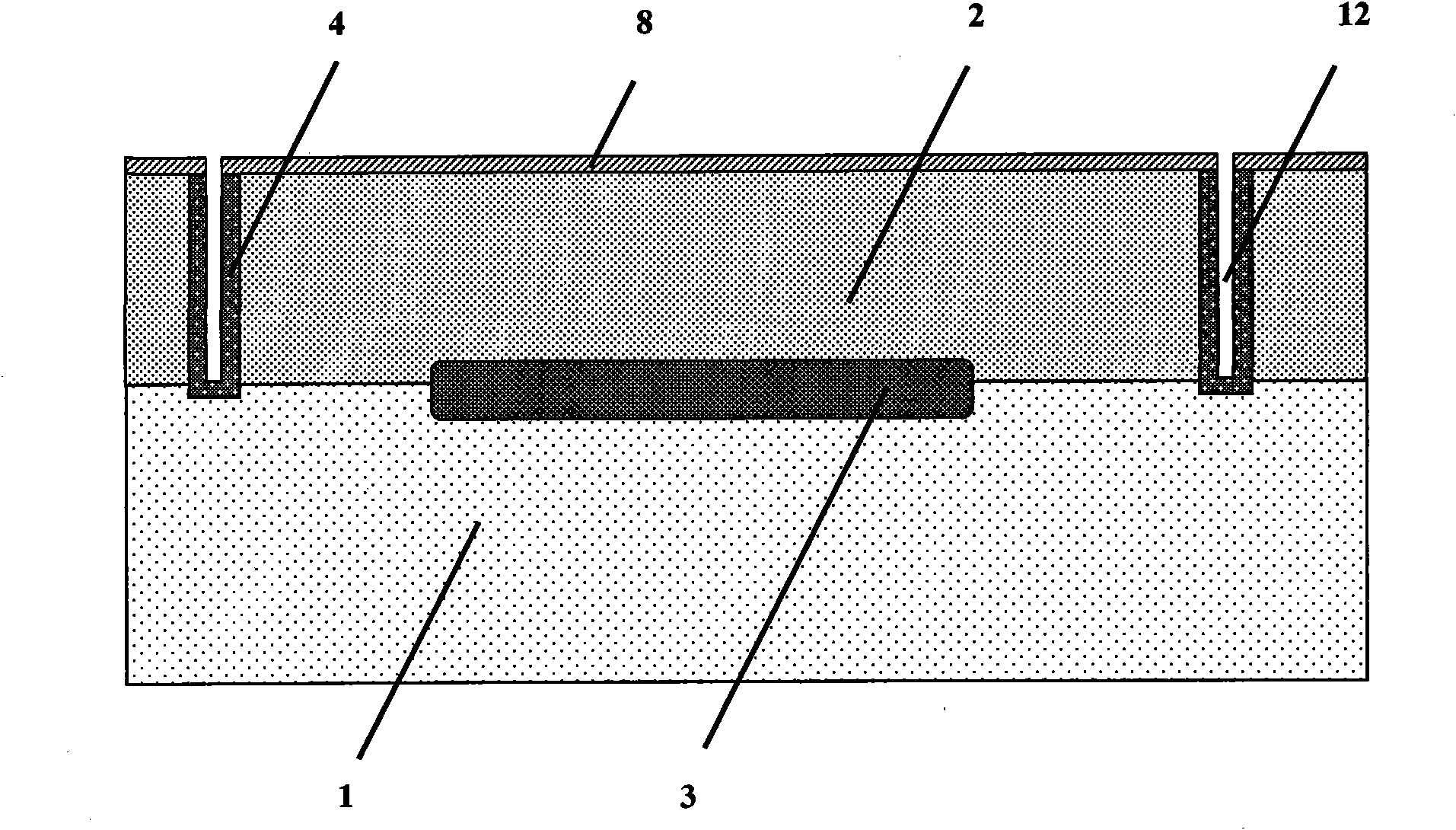

[0030] The specific implementation of the present invention is not limited to the semiconductor device described below, but also can increase the integration density of high-voltage integrated circuit devices by adopting various similar methods well known in the industry that can meet the requirements of this manufacturing method according to the core and design spirit of this method the goal of.

[0031] Taking a 40V high-voltage bipolar integrated circuit as an example, the specific implementation steps of a semiconductor structure and a manufacturing method for increasing the integration density of high-voltage integrated circuit devices of the present invention are as follows:

[0032] 1. On a 7-20Ω.cm, P-type semiconductor substrate 1, a 600-650nm oxide layer is formed by oxidation or CVD low deposition methods commonly used in the industry, and a 30-50nm oxide layer is formed by photolithography and thin oxygen, and then 150KeV, (2~8)×10 15 cm -2 , As ion implantation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com