Desulfuration waste liquid treatment process and equipment

A technology for desulfurization waste liquid and treatment process, which is applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problem of lack of treatment technology and equipment, high treatment cost and high equipment investment. problems, to achieve the effect of short process flow, thorough reaction and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

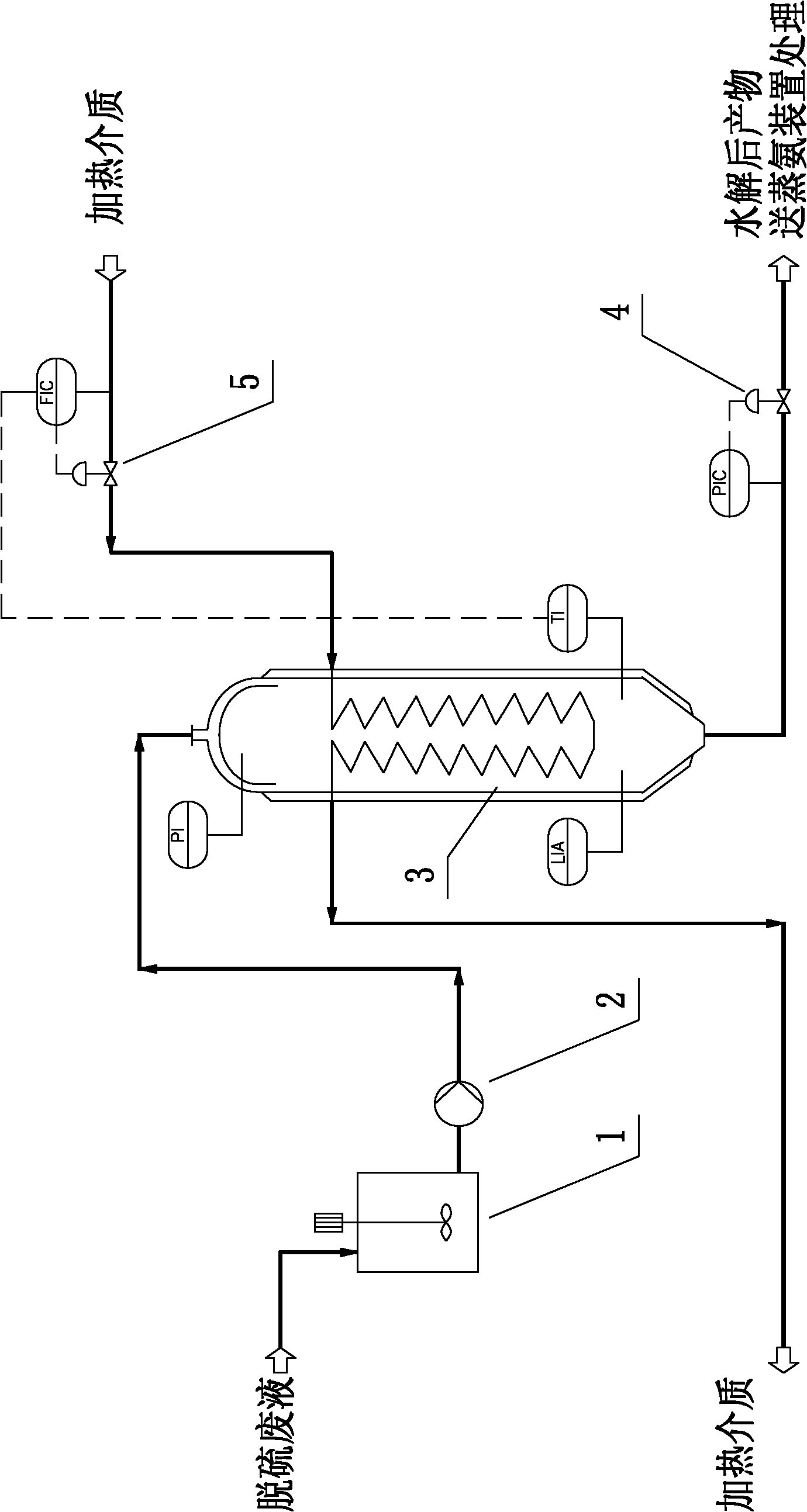

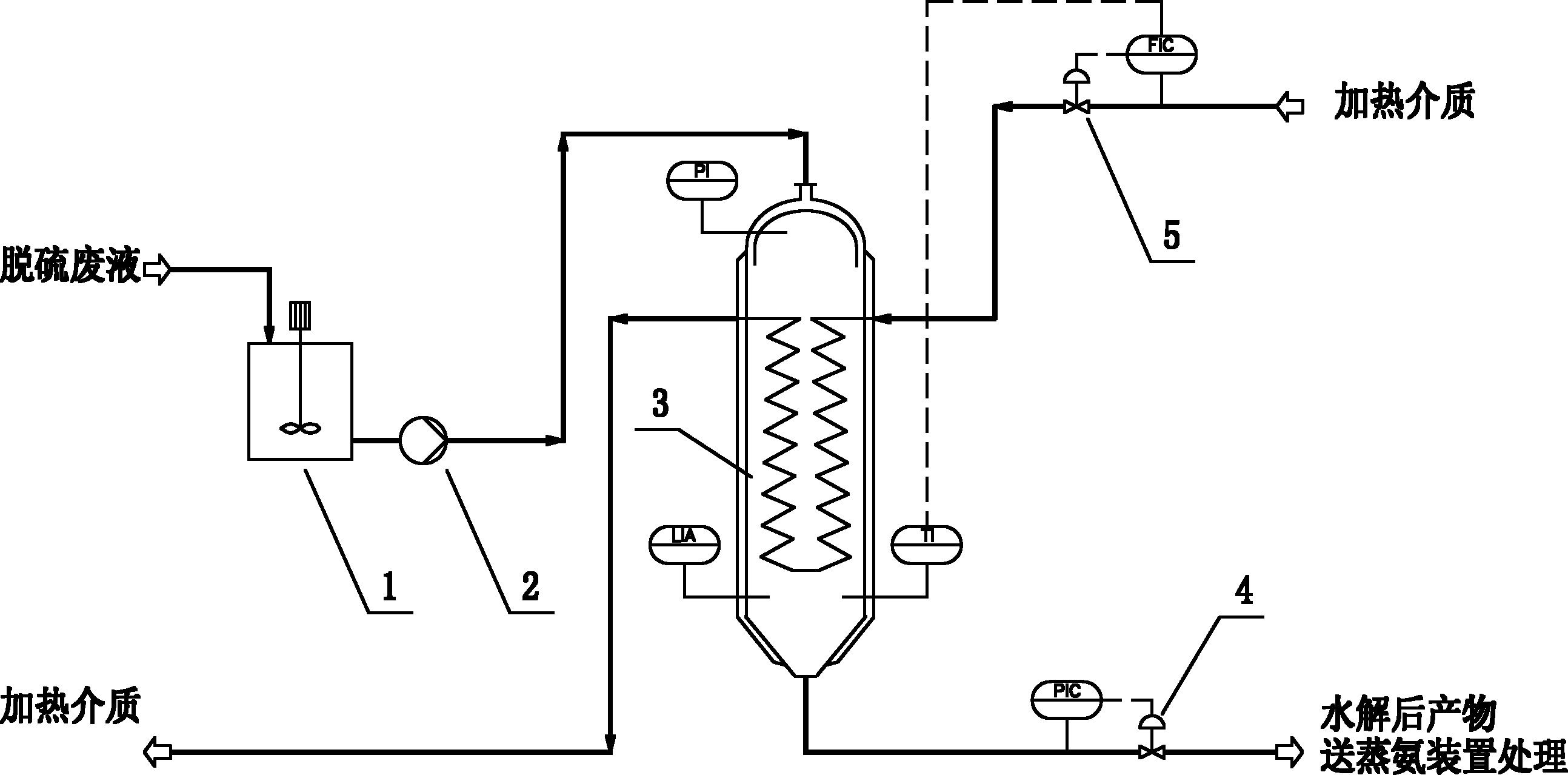

[0030] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] See figure 1 , a process for the treatment of gas desulfurization waste liquid by vacuum potassium carbonate method, the process adopts the method of heating and hydrolysis to treat the desulfurization waste liquid, and sends the desulfurization waste liquid into the airtight hydrolysis reactor 3, so that it can be heated at a certain temperature and Under pressure conditions, the cyanide in the desulfurization waste liquid is hydrolyzed into non-toxic or slightly toxic compounds such as formate and ammonia, and the hydrolyzed products are directly sent to the ammonia distillation tower. The hydrolysis reaction temperature is 110°C-230°C; the hydrolysis reaction pressure is 3-10MPa; the hydrolysis reaction time is 10-80min; the alkalinity PH of the desulfurization waste liquid is ≥ 8.5.

[0032] In the hydrolysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com