Method for preparing microwave-assisted non ball milling rare-earth superfine powder

An ultra-fine powder, microwave-assisted technology, used in chemical instruments and methods, luminescent materials, etc., can solve problems such as small particle size, and achieve the effect of reducing sintering problems, reducing workload, and having great potential for industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

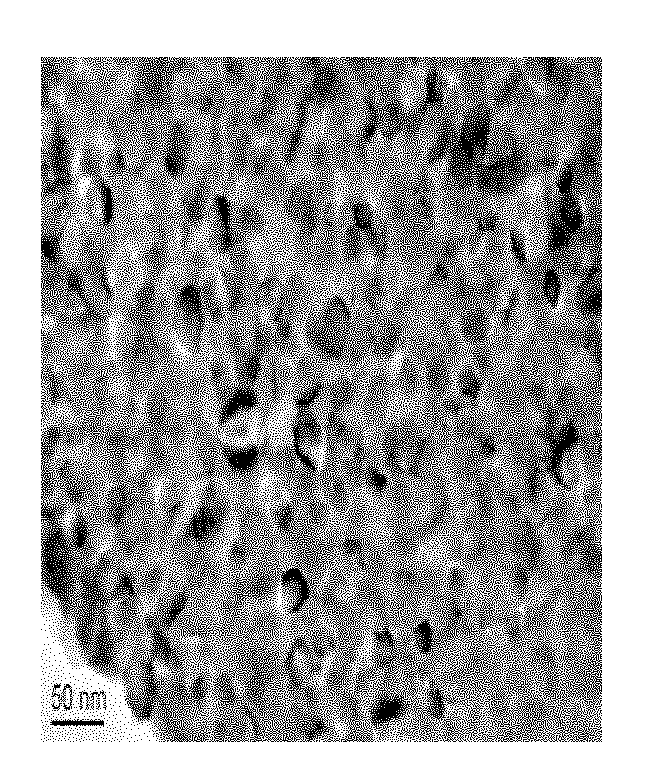

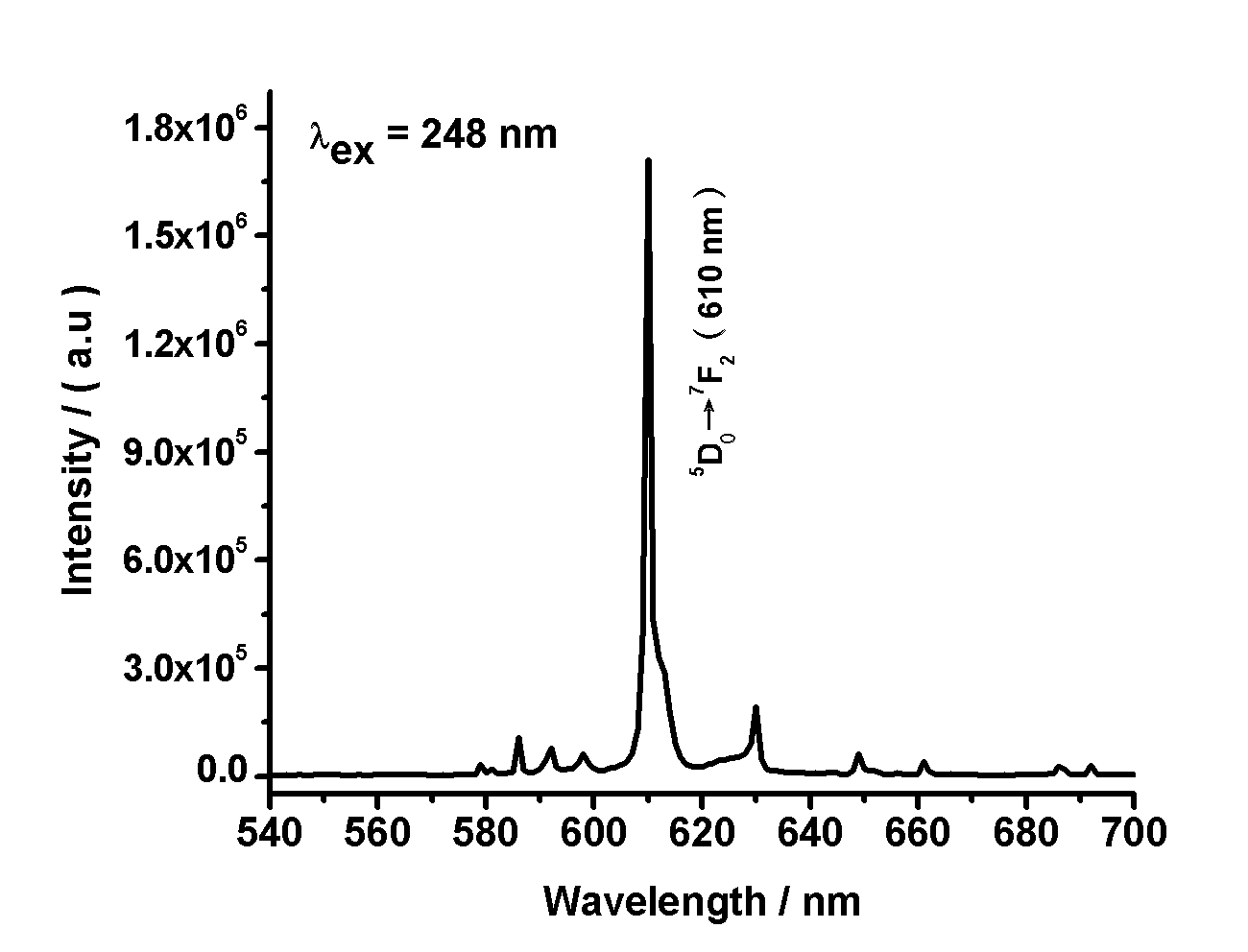

[0031] According to chemical formula Y 2 o 3 :Eu x The molar ratio in (x=0.1) takes Y(NO 3 ) 3 and Eu(NO 3 ) 3 , add water to dissolve. In the process of stirring, add citric acid with twice the molar weight of the total metal ions, and stir until a homogeneous liquid. Adjust the pH to alkaline (no precipitation occurs), then back-adjust to pH 5 with acid, and stir evenly. Transfer the mixed liquid to a microwave system, irradiate for 10 minutes under microwave 480W, and keep the obtained powder at 400°C for 2h, and then keep warm at 600 and 800°C for 1h each to obtain rare earth ultrafine powder Y 2 o 3 :Eu.

Embodiment 2

[0033] According to chemical formula Y 2 o 3 :Eu x The molar ratio in (x=0.1) takes Y(NO 3 ) 3 and Eu(NO 3 ) 3 , add water to dissolve. During the stirring process, add citric acid with 2. times the molar weight of the total metal ions, and stir until a homogeneous liquid. Adjust the pH to alkaline (no precipitation occurs), then back-adjust to pH 6 with acid, and stir evenly. Transfer the mixed liquid to a microwave system, irradiate for 10 minutes under microwave 480W, and keep the obtained powder at 400°C for 1h, and then keep it at 800°C for 2h to obtain rare earth ultrafine powder Y 2 o 3 :Eu.

Embodiment 3

[0035] According to chemical formula Y 2 o3 :Eu x The molar ratio in (x=0.15) takes YCl 3 and EuCl 3 , add water to dissolve. In the process of stirring, add EDTA complexing agent with 2.5 times the molar weight of total metal ions, and stir until a homogeneous liquid. Adjust the pH to alkaline (no precipitation occurs), then back-adjust to pH 7 with acid, and stir evenly. Transfer the mixed solution to a microwave system, irradiate for 15 minutes under microwave 320W, and keep the obtained powder at 400°C for 2h, and at 600°C and 800°C for 1h each to obtain rare earth ultrafine powder Y 2 o 3 :Eu.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com