Method for improving magnetic property of oriented silicon steel through laser scribing

A technology of oriented silicon steel and laser scoring, which is applied in the directions of laser welding equipment, inorganic material magnetism, furnace type, etc., can solve the problems of large plate shape damage, frequent maintenance, and reduced magnetic induction of oriented silicon steel sheets, so as to improve the quality and grade , Overcoming frequent maintenance and no deterioration of magnetic induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The method for improving the magnetic properties of grain-oriented silicon steel by laser marking of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples:

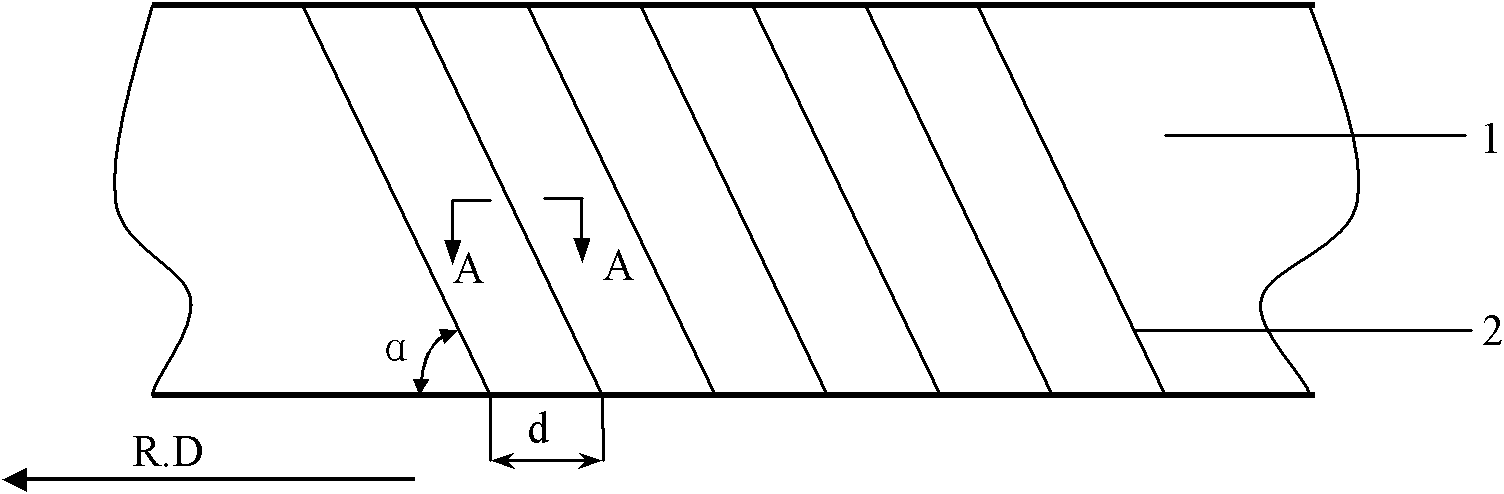

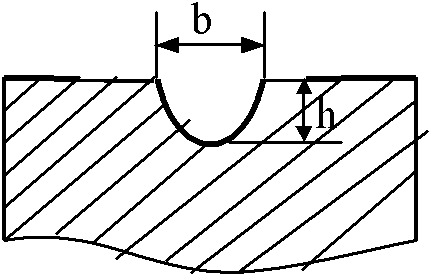

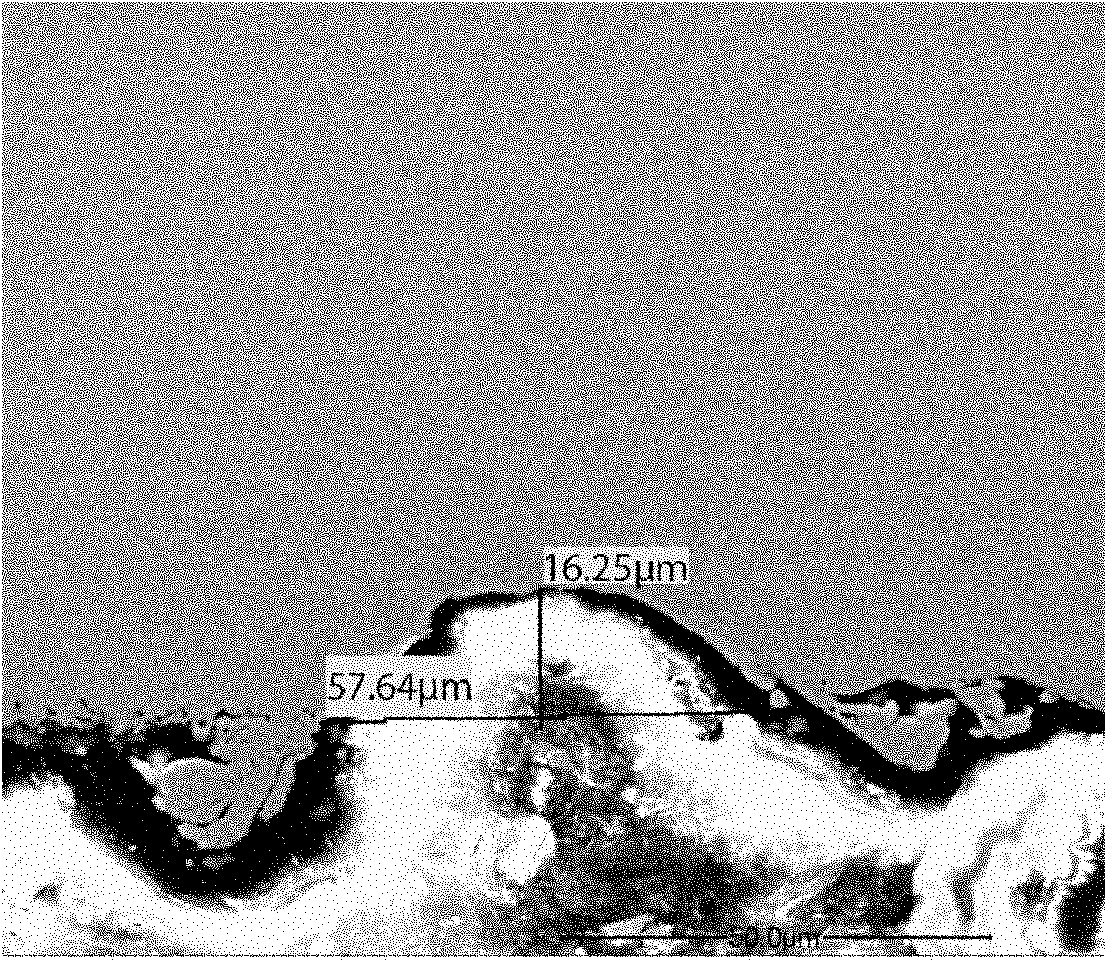

[0025] As shown in Figures 1 and 2, linear or dotted grooves 2 are engraved on the surface of the high magnetic induction oriented silicon steel sheet 1, and each linear or dotted groove 2 is aligned with the rolling direction of the oriented silicon steel sheet 1 (Fig. The included angle α=78~88° in the R.D direction) shown in , the distance between adjacent linear or dotted linear grooves 2 along the rolling direction of grain-oriented silicon steel sheet 1 is d=3~5mm, each line or dot The groove depth h of the linear groove 2 is 15 to 30 μm, and the groove width b is 50 to 65 μm. It is obtained by the following method: adjusting the working parameters of the laser beam produced by the fiber laser to the following range: spot diameter D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com