Buffer layer of flexible thin film solar cell and preparation method thereof

A technology of solar cells and flexible films, applied in circuits, electrical components, climate sustainability, etc., can solve problems such as metal cadmium environmental pollution, avoid pollution, improve band gap and resistivity, and solve high resistivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0042]The medicines of this embodiment are analytical reagents, and the aqueous solution is prepared with deionized water. The specific steps are as follows:

[0043] Weigh a certain amount of ZnSO 4 , the ZnSO 4 Prepare a solution of 0.02mol / L; weigh a certain amount of thiourea, dissolve it in deionized water to make a solution with a concentration of 1.0mol / L; weigh a certain amount of CuSO 4 , the CuSO 4 Prepared into a 0.02mol / L solution. First mix 20ml of the prepared zinc sulfate solution, 20ml of copper sulfate solution and 20ml of ammonia water (0.2mol / L) into the reactor, then add 10ml of thiourea solution and mix, and finally add deionized water until the volume of the entire mixed solution is 200ml , adjust the pH value of the mixed solution to about 8.5-8.8, put it into the deposition substrate, place the reactor in a water bath and heat it to 70°C to react, and form a buffer layer on the substrate, and the reaction time is 0.5h. The deposited substrate was ta...

Embodiment approach 2

[0045] The medicines used in this embodiment are analytical reagents, and the aqueous solution is prepared with deionized water. Specifically include the following steps:

[0046] Weigh a certain amount of ZnSO 4 , the ZnSO 4 Prepare a solution of 0.02mol / L; weigh a certain amount of thiourea, dissolve it in deionized water to make a solution with a concentration of 1.0mol / L, and weigh a certain amount of FeSO 4 , FeSO 4 Prepared into a 0.01mol / L solution. First, 20ml of the prepared zinc sulfate solution, 10ml of ferric sulfite solution and 20ml of ammonia (0.2mol / L) are mixed and placed in the reactor, then 10ml of thiourea solution is added to mix, and finally deionized water is added until the volume of the whole mixed solution is 200ml, adjust the pH value to about 9-9.5, put it into the deposition substrate, place the reactor in a water bath and heat it to 70°C to react to form a buffer layer, and the reaction time is 40min. The deposited substrate was taken out, wa...

Embodiment approach 3

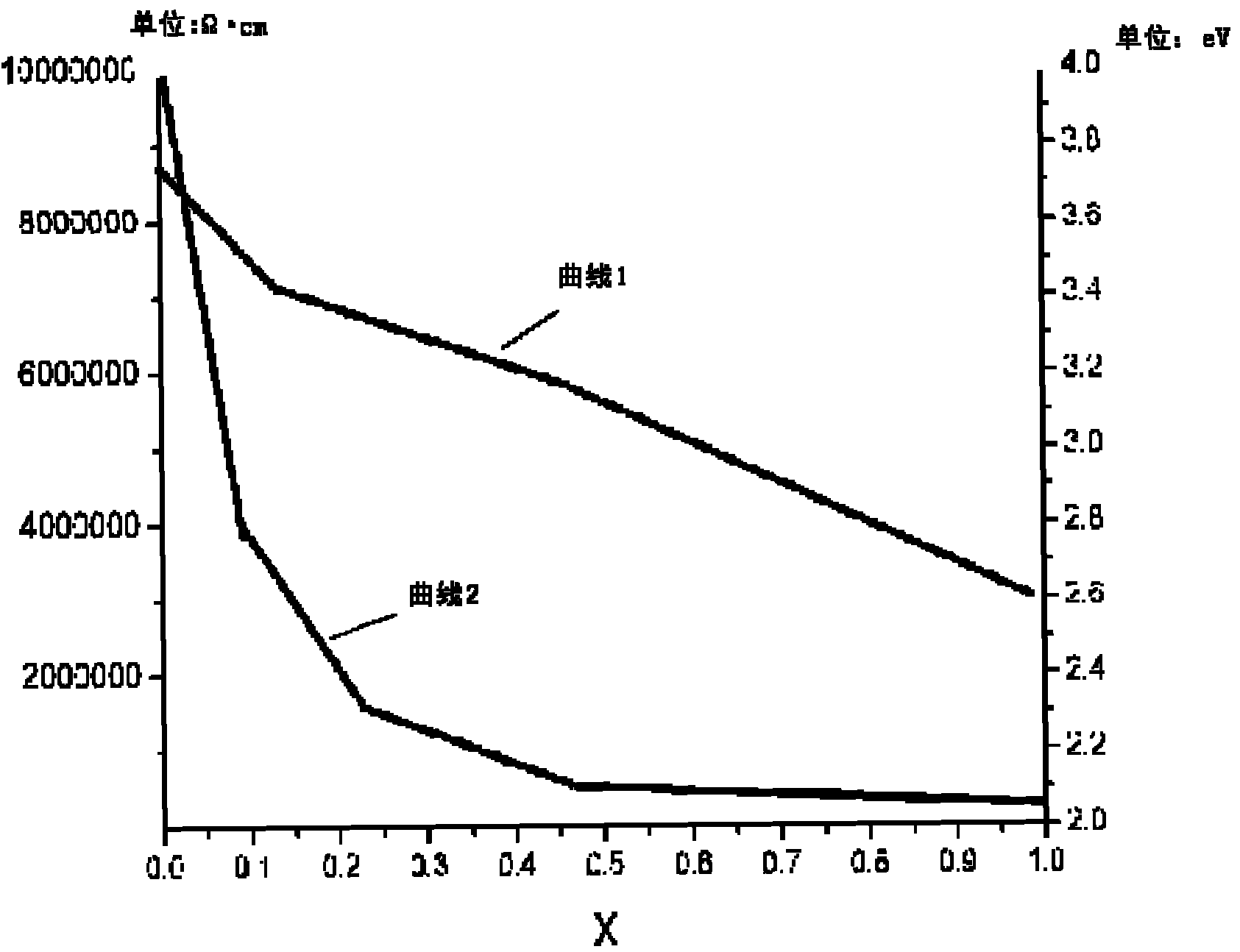

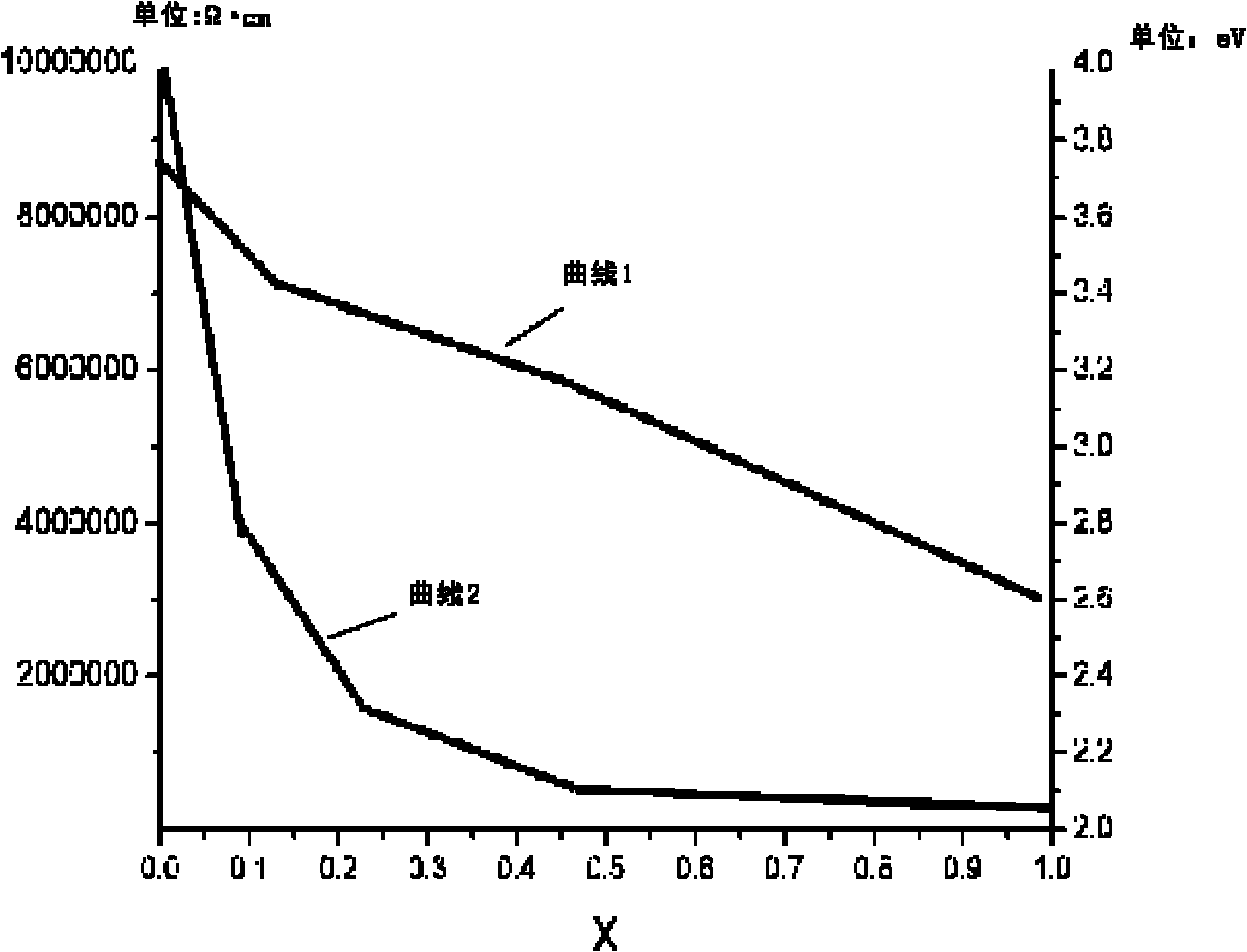

[0048] Weigh a certain amount of ZnCl 2 , the ZnCl 2 Prepare a solution of 0.03mol / L; weigh a certain amount of thiourea, dissolve it in deionized water to make a solution with a concentration of 1.5mol / L, and weigh a certain amount of FeCl 2 , the FeCl 2 Prepared into a 0.02mol / L solution. First mix 20ml of zinc chloride solution, 10ml of ferrous chloride solution and 20ml of ammonia water (0.2mol / L) and place in the reactor, then add 10ml of prepared thiourea solution and mix, and finally add deionized water until the whole mix The volume of the solution is 200ml, adjust the pH value to about 8.5-8.8, put it into the deposition substrate, place the reactor in a water bath and heat it to 60°C to react to form a buffer layer, and the reaction time is 0.5h. The deposited substrate was taken out, washed with deionized water, and then dried with nitrogen to obtain a Fe-doped ZnS film with a thickness of about 60nm, a bandgap width of 3.1eV, and a resistivity of about 10 5 Ω·c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Band gap width | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com