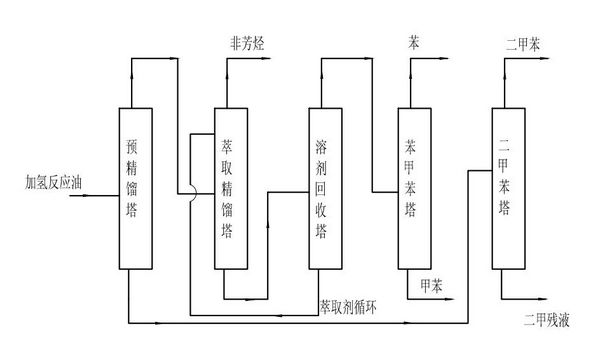

Separating and purifying device and process for heavy-component residual liquid of hydrogenation process of coking crude benzene

A technology for coking crude benzene and heavy components, applied in the field of rectification, can solve problems such as waste of resources, and achieve the effects of less investment in equipment, high separation efficiency, and good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

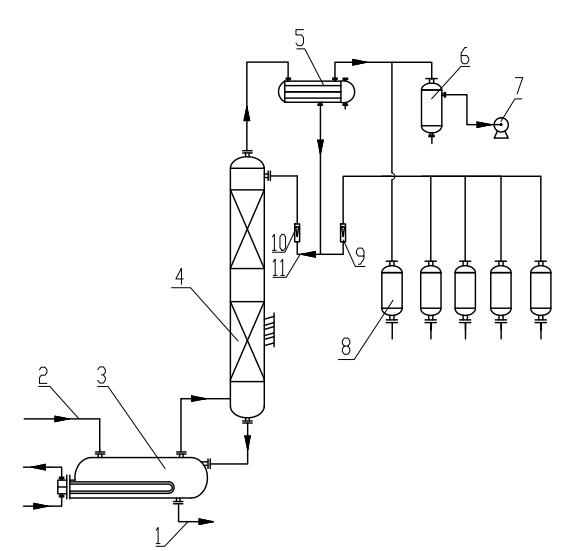

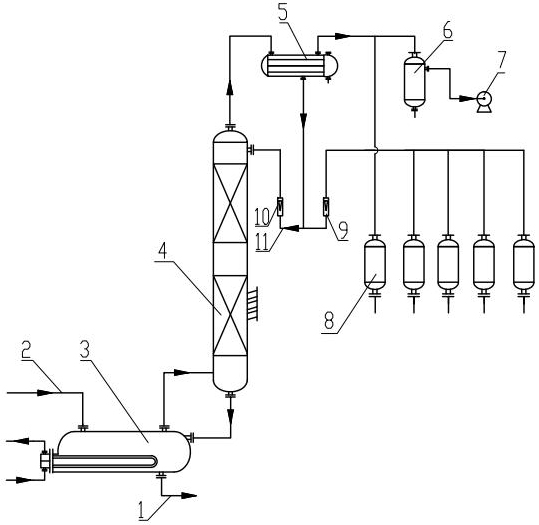

Method used

Image

Examples

Embodiment 1

[0022] In this example, the heavy component raffinate of the coking crude benzene hydrogenation process provided by a certain enterprise is taken as an example to illustrate the operation steps of the above-mentioned separation and purification device.

[0023] The composition of the heavy component raffinate in the coking crude benzene hydrogenation process is shown in Table 1.

[0024] Table 1 Components and contents of heavy component raffinate in coking crude benzene hydrogenation process

[0025]

[0026] Take 1.5L of the heavy component raffinate of the above-mentioned coking crude benzene hydrogenation process. The batch rectification tower is φ30mm×4000mm, the tower is filled with high-efficiency wire mesh packing, and the tower kettle is 2.0L. The process conditions for batch distillation are:

[0027] ①The total reflux operation is carried out at 40.0kPa operating pressure for about 1 hour, the temperature at the top of the tower is 60.0°C and after the pressure...

Embodiment 2

[0032] Take 1.6L of the heavy component raffinate of the coking crude benzene hydrogenation process of an enterprise, its composition and the batch rectification device adopted are the same as those described in Implementation 1. Batch distillation operation process:

[0033] ① Carry out total reflux operation at an operating pressure of 50.0kPa for about 1 hour, the temperature at the top of the tower is 65.0°C and after the pressure of the whole tower is stabilized, the light component product is extracted from the top of the tower with a reflux ratio of 3:1;

[0034] ②After the extraction of light components is completed, under the operating pressure of 15.0kPa, the temperature at the top of the tower is 120.0°C and the whole tower is stable, and the indane product is extracted from the top of the tower with a reflux ratio of 5:1;

[0035] ③After indane extraction is completed, under the operating pressure of 15.0kPa, the temperature at the top of the tower is 130°C and the...

Embodiment 3

[0038] Take 1.7L of the heavy component raffinate of the double coking crude benzene hydrogenation process of a certain enterprise, and its composition and the vacuum intermittent rectification device used are the same as those described in implementation 1. Batch distillation operation process:

[0039] ①The total reflux operation is carried out at 45.0KPa operating pressure for about 1 hour, the temperature at the top of the tower is 62.0°C and after the pressure of the whole tower is stabilized, the light component product is extracted from the top of the tower with a reflux ratio of 2:1;

[0040] ② After the extraction of light components is completed, under the operating pressure of 12.0kPa, the temperature at the top of the tower is 118.0°C and the whole tower is stable, and the indane product is extracted from the top of the tower with a reflux ratio of 4:1;

[0041] ③After indane extraction is completed, under the operating pressure of 13.0kPa, the temperature at the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com