Controllable cation polymerizing method of vinyl monomers

A vinyl monomer and cationic polymerization technology, which is applied in the field of vinyl monomer carbocation controllable polymerization, can solve the problems such as narrowing of the molecular weight of the polymerization product, and achieve the effects of improving the initiation efficiency, reducing the dosage, and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

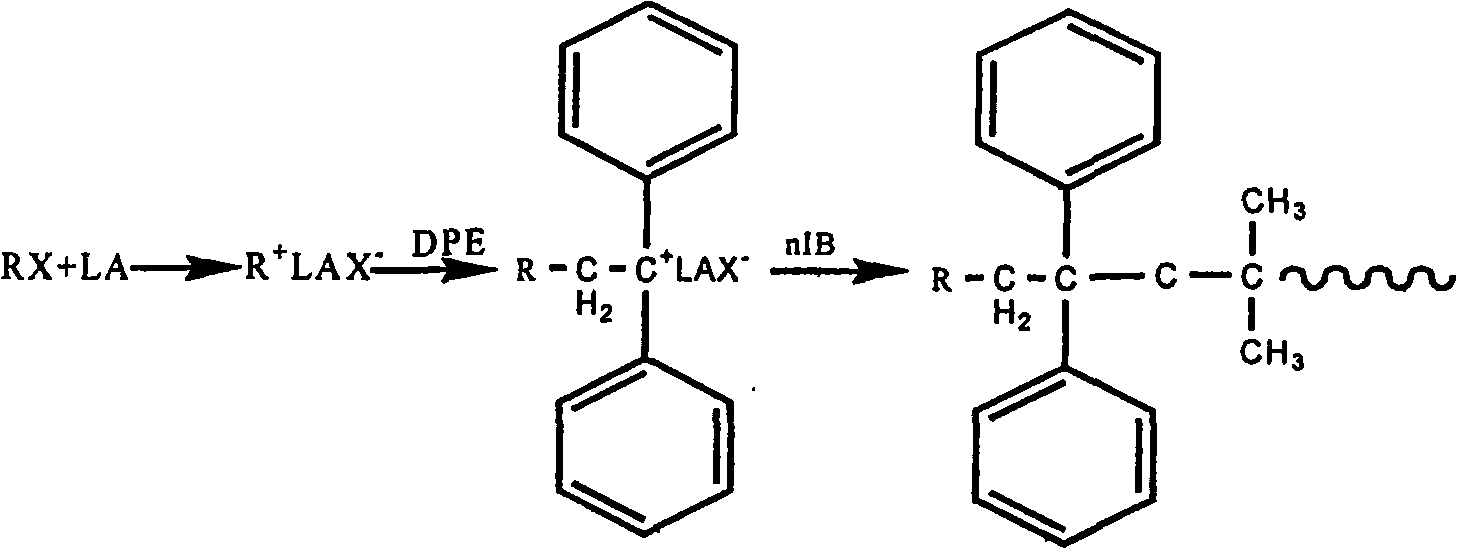

[0026] Under the condition of -80℃ and high-purity nitrogen protection, the H 2 O (0.014mmol), AlCl 3 (0.033mmol), dichloromethane (5mL), 1,1-diphenylethylene (0.0033mmol) and triphenylamine (0.0033mmol) were added to the dry initiation system preparation device and mixed evenly to obtain blood red homogeneous transparent triggering system.

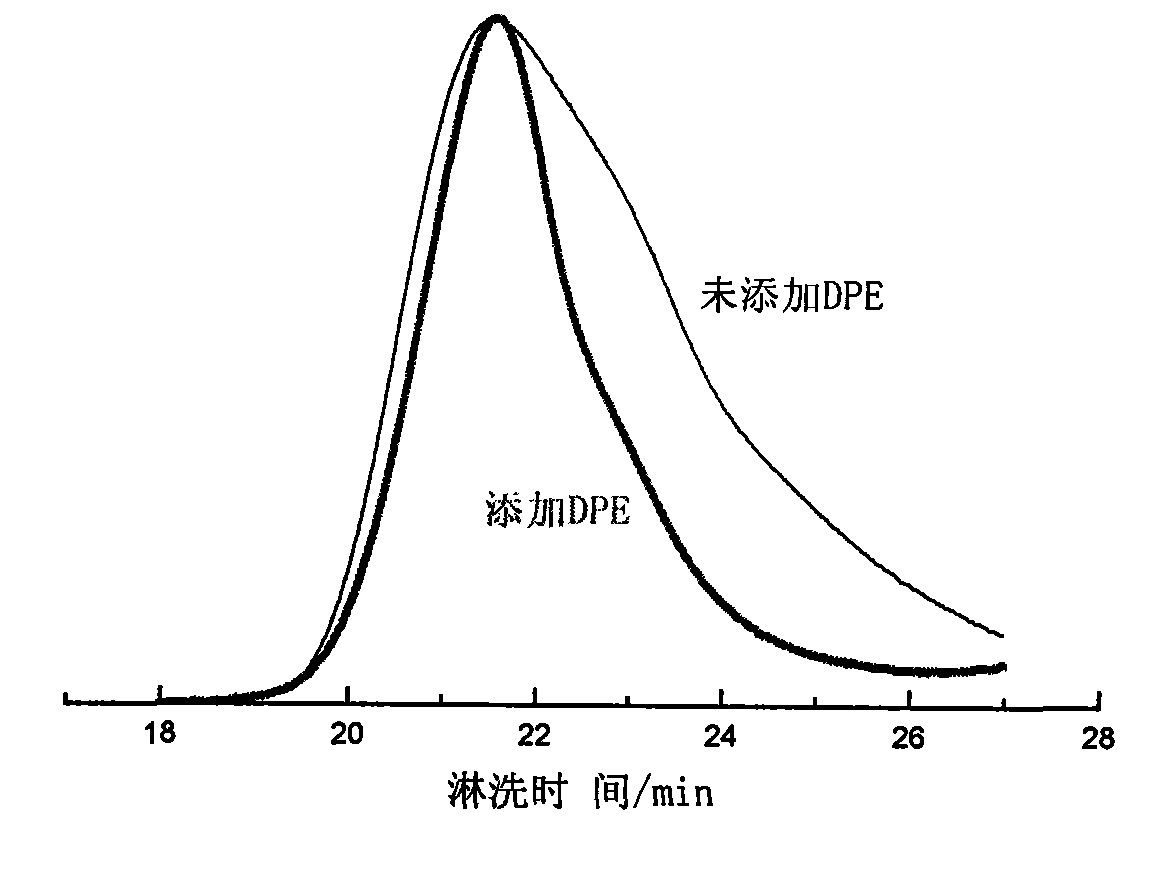

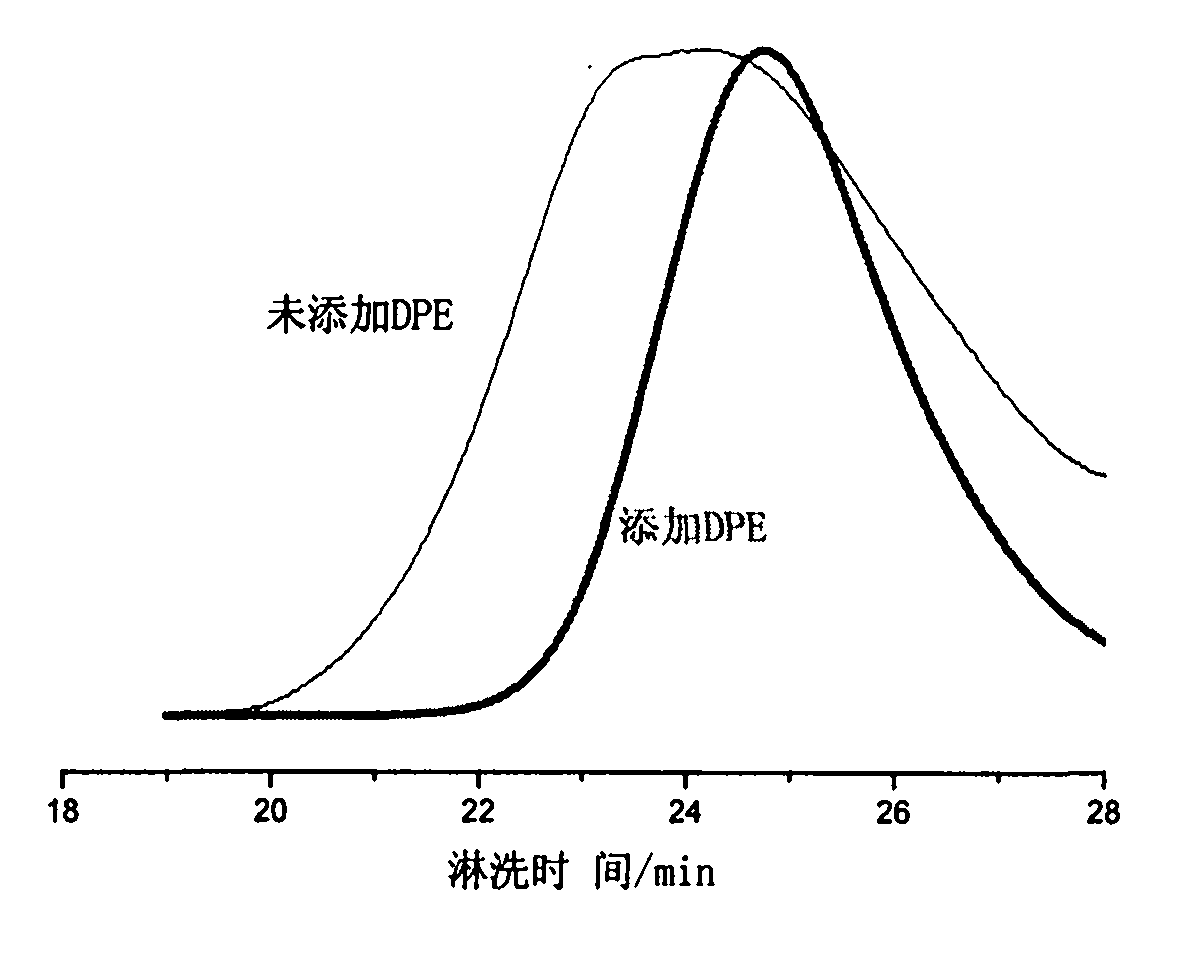

[0027] Under the protection of high-purity nitrogen, add 20mL of monomer mixed solution of isobutylene (IB) / n-hexane / dichloromethane to the polymerization reactor (the volume ratio of n-hexane / dichloromethane is 3.2, and the molar concentration of monomer is 0.8mol / L), then add the above-mentioned initiation system, so that in the polymerization system [AlCl 3 ] / [IB]=2.1×10 -3 . After the polymerization reaction at -80° C. for 1 h, a precooled 5 mL NaOH / ethanol mixed solution (the mass fraction of NaOH was 5%) was added to terminate the polymerization. The solvent and unreacted monomers were removed, and the polymer product was obta...

Embodiment 2

[0029] The preparation method, polymerization reaction and post-treatment method of the initiation system are as described in Example 1, but the amount of 1,1-diphenylethylene (0.043mmol) is changed, that is, [1,1-diphenylethylene]:[AlCl 3 ] = 1.3. Polyisobutylene product yield 76%, M n 7.5×10 4 ,M w / M n is 1.8.

Embodiment 3

[0031] The preparation method of the initiation system, the polymerization process and the post-treatment method are as in Example 1, only changing the amount of 1,1-diphenylethylene (0.132mmol), [1,1-diphenylethylene]:[AlCl 3 ]=4. Polyisobutylene product yield is 20%, M n 2.7×10 4 ,M w / M n is 1.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com