Single lens reflex semipermeable membrane lens and preparation method thereof

A technology of semi-transparent film and SLR camera, which is applied in the direction of camera, camera body, installation, etc., can solve the problems of lower transmittance, performance degradation of polymer film, etc., achieve high mechanical strength, reduce electrostatic carrying capacity, and implement effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

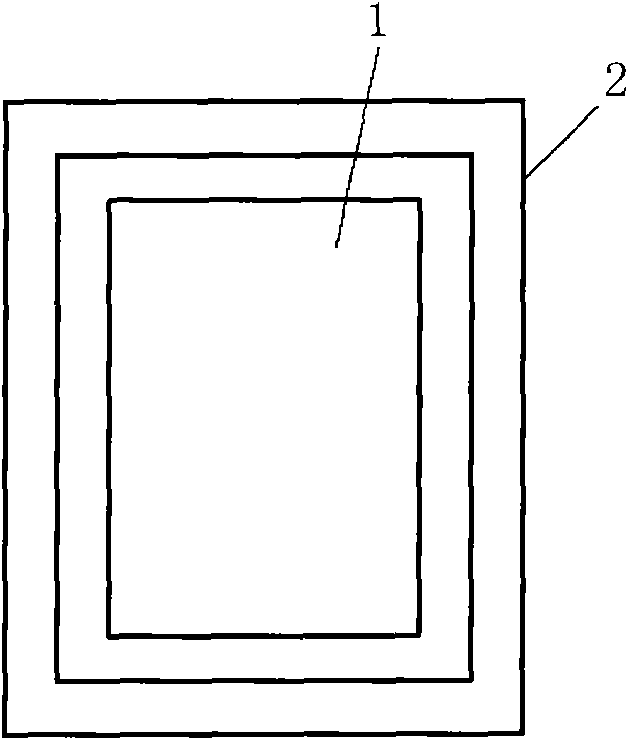

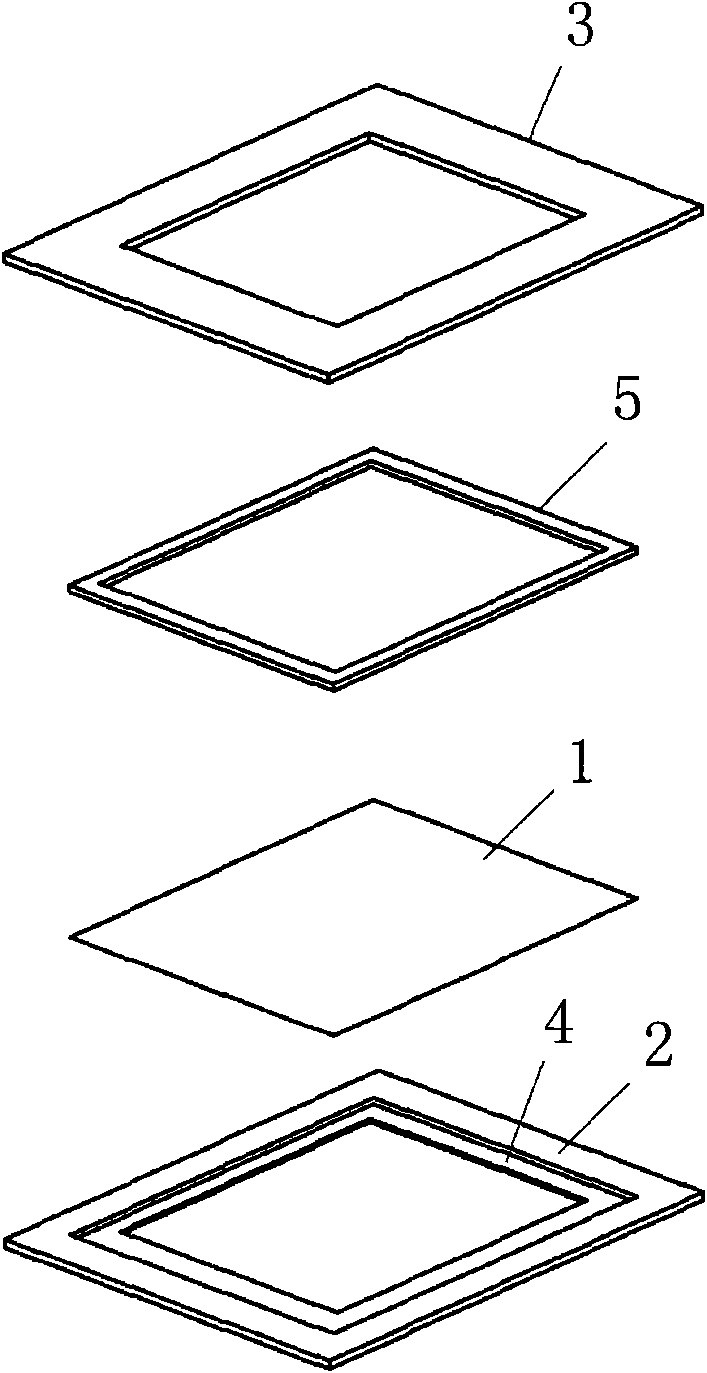

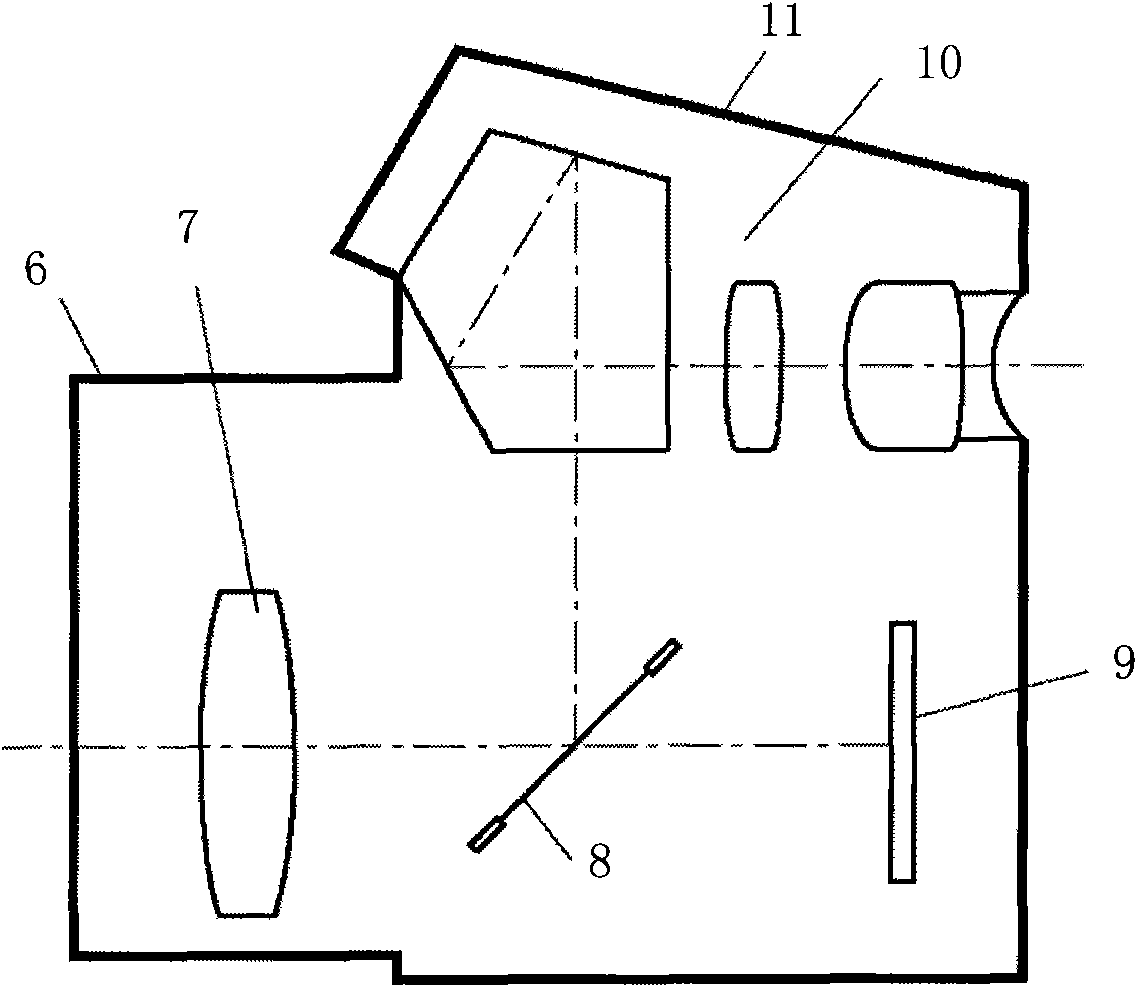

[0033] Such as figure 1 , 2 The shown semi-transparent film lens 8 for a SLR camera includes a semi-transparent film lens body 1, and its special feature is that the thickness of the semi-transparent film lens body 1 is less than 0.1 mm, preferably 0.03 mm. Specifically, its materials include crystal, sapphire, and tempered glass. The bottom side of the semi-transparent film lens body 1 is provided with a hollow matrix 2, and the top of the semi-transparent film lens body 1 is provided with a hollow top cover 3, and the film is embedded in the hollow matrix 2. Between the drop grooves 4, a buffer material 5 is mixed in the edge of the film surface side, and the hollowed out parts of the hollowed out matrix 2 and the hollowed out top cover 3 correspond to each other.

[0034] In conjunction with a preferred embodiment of the present invention, one side or both sides of the semi-transparent film lens body 1 are coated with a film layer, which includes TiO 2 2 films, SiO 2 mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com