Device for reducing polymers at back side of substrate

A polymer and substrate technology, applied in crystal growth, electrical components, climate sustainability, etc., can solve problems such as the backside of the substrate, the temperature rise of the intermediate ring, polymer deposition, etc., and achieve reliable and stable setting and positioning. The effect of increasing the speed of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

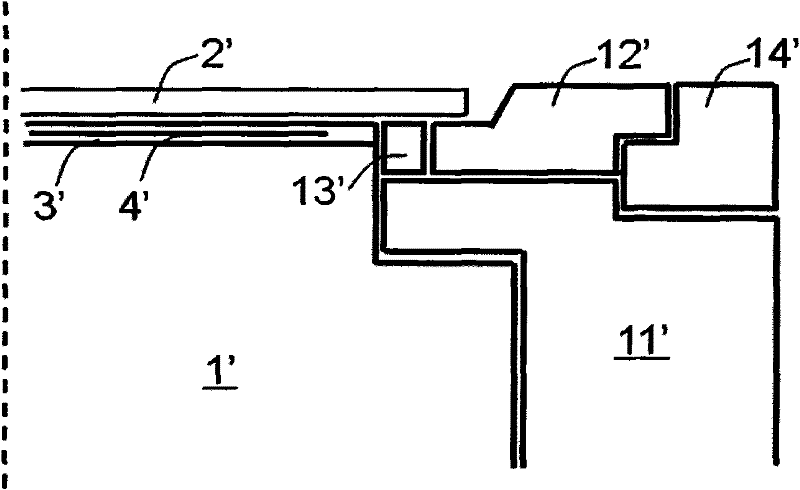

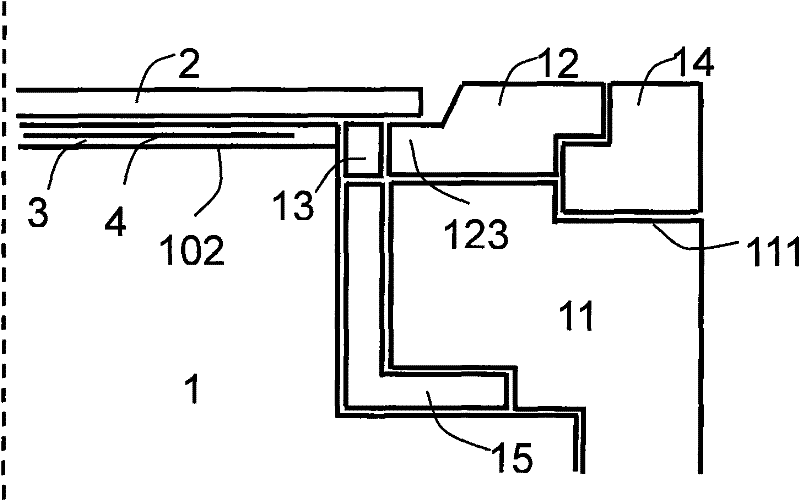

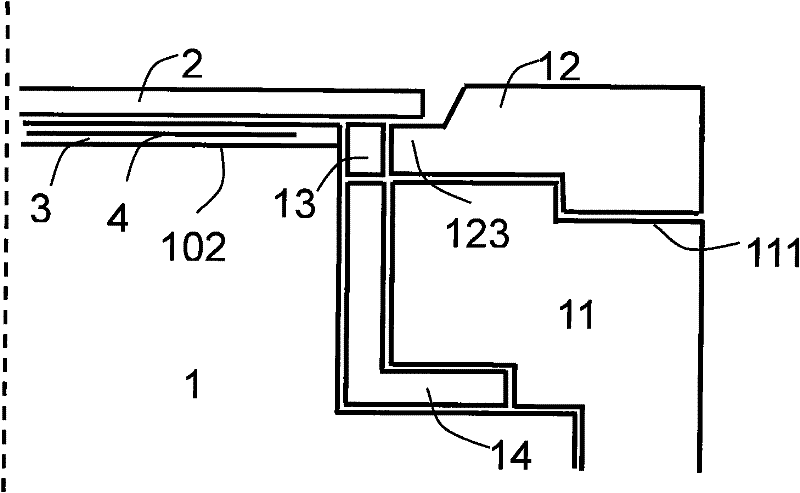

[0041] The following combination Figure 2 to Figure 5 , the present invention will be described in detail through several preferred specific embodiments.

[0042] Such as figure 2 Shown is an embodiment of the device for reducing polymer on the backside of the substrate described in the present invention. In this embodiment, a substrate 2 and a base 1 are provided in the plasma etching chamber for performing plasma etching on the substrate, and a substrate support for installing the substrate 2 is also provided on the upper surface 102 of the base. The substrate support includes an electrostatic chuck 3 usually made of ceramic material and a DC electrode 4 embedded in the electrostatic chuck 3; after the substrate 2 is installed on the substrate support, Its edge protrudes from the edge of the upper surface 102 of the base 1 (and also protrudes from the edge of the electrostatic chuck 3). The plasma etching chamber also includes an insulating ring 11 that is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com