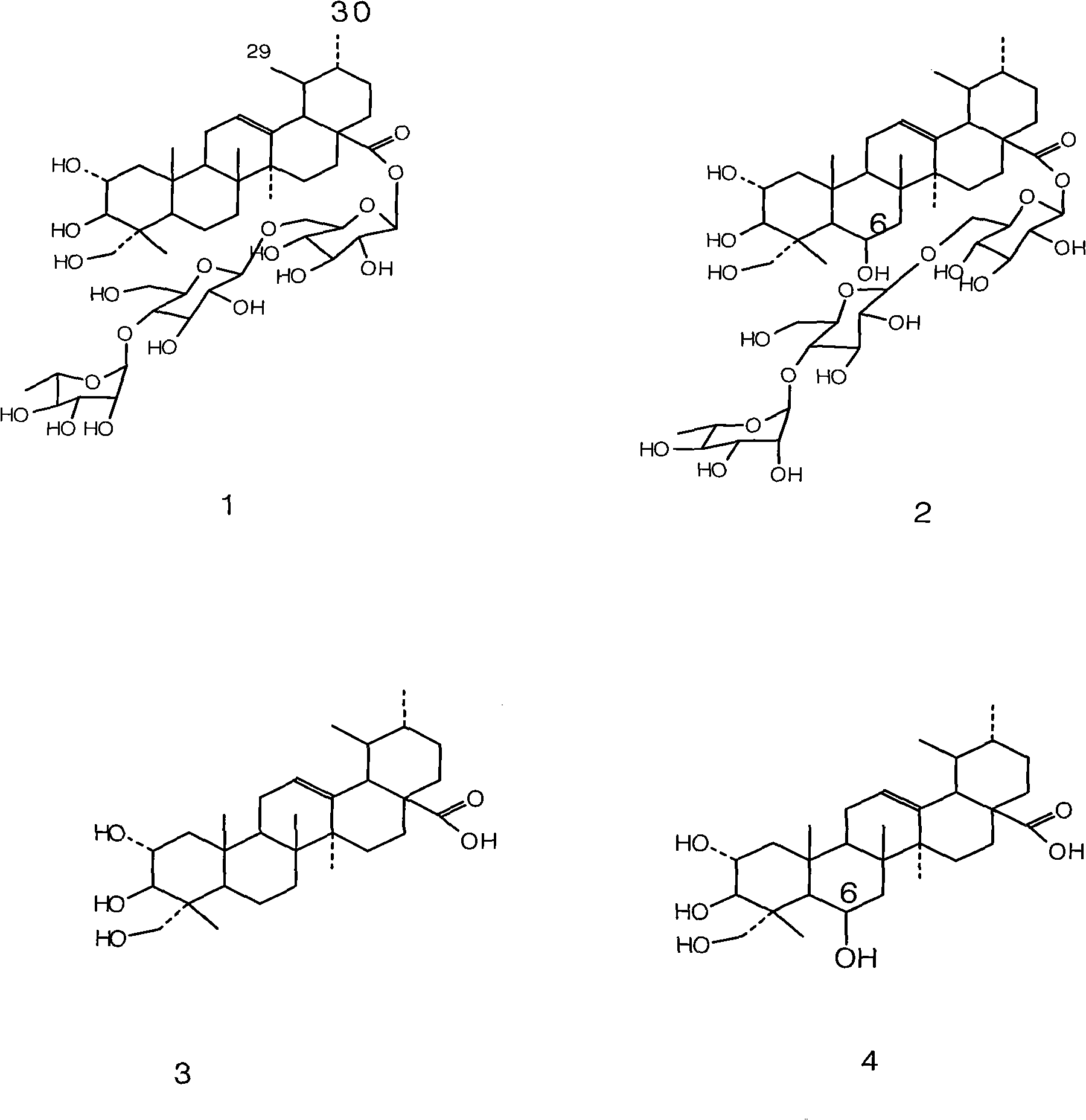

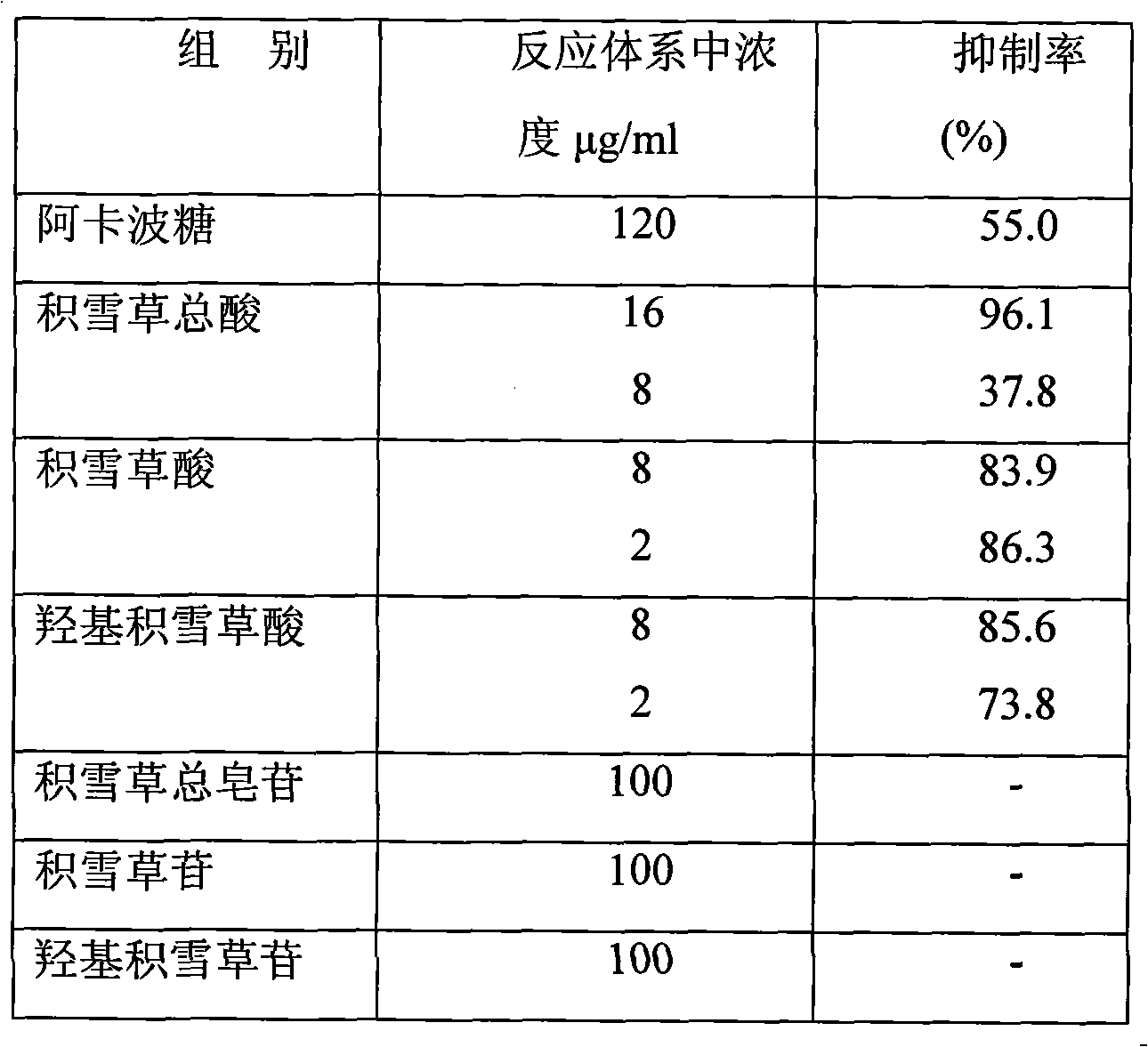

Method for preparing total asiatic acid, asiatic acid and madecassic acid from asiatic pennywort herb and use of prepared product

A technology of madecassoic acid and madecassoic acid is applied in the directions of drug combinations, pharmaceutical formulations, steroids, etc., which can solve the problems of time-consuming and labor-intensive, solvent consumption, inability to prepare madecassoside at the same time, etc. Low cost, good for promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The present invention is further described below:

[0023] Extraction of Centella asiatica total saponins:

[0024] Whole grass coarse powder 1Kg, add 10 liters of water to reflux and extract three times, each time for 1.5 hours, filter, combine the filtrate, concentrate under reduced pressure to a specific gravity of 1.1, add three times the volume of 95% alcohol for precipitation, leave overnight, filter, and decompress the filtrate Concentrate to dryness to obtain 51g, which is the total saponins of Centella asiatica, with a yield of 5.1%.

[0025] Also use 1 kg of whole herb coarse powder, add 10 liters of 60% alcohol to reflux and extract three times, each time for 1.5 hours, the following operations are the same as above, and 56 g of total saponins are obtained, with a yield of 5.6%.

[0026] Preparation of Centella asiatic acid:

[0027] Add 51g of the above-mentioned total saponins of Centella asiatica, add 200ml of 1% potassium hydroxide solution, heat and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com