Preparation method of chickpea total saponin

A technology of chickpea and total saponins, which is applied in the field of preparation of total chickpea saponins, can solve the problems of complex operation, inapplicability to industrial production, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

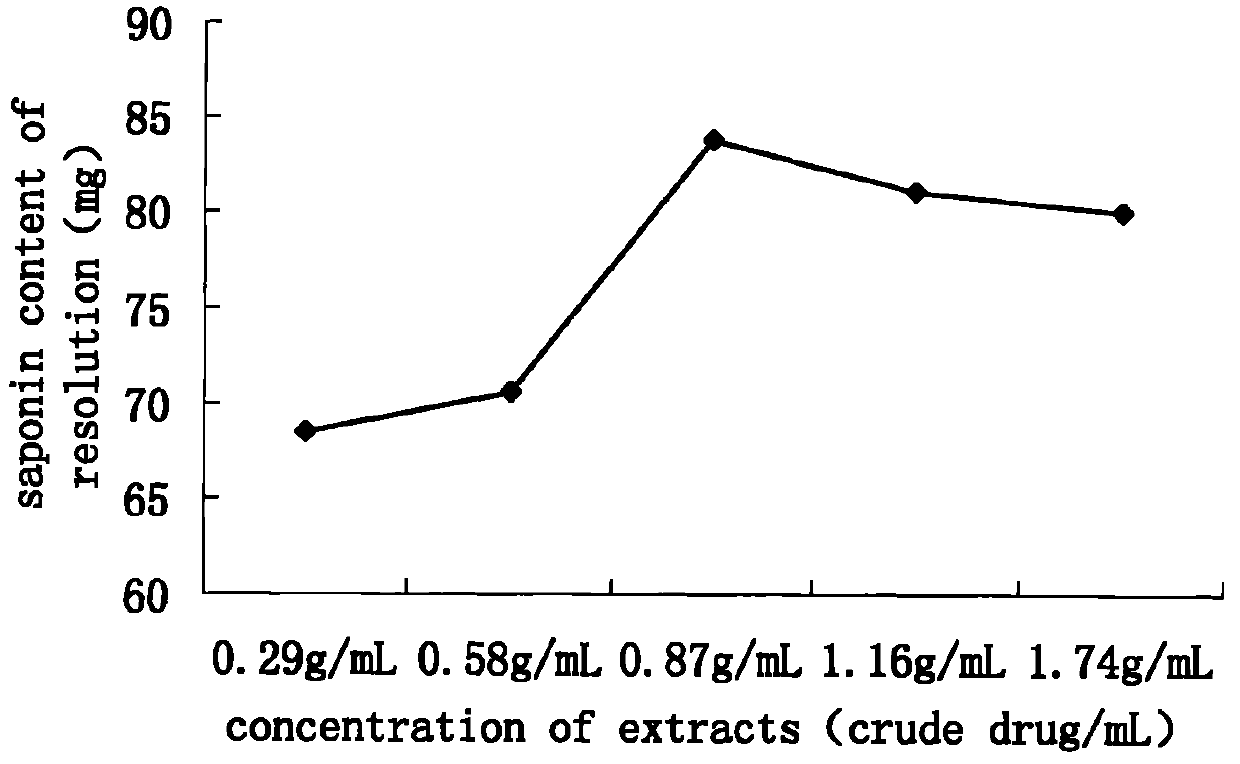

[0052] a. Crush the chickpeas, pass through a 40-mesh sieve, take 500g of chickpea flour, add 6# solvent oil, and use a water bath to heat and reflux to degrease. The heating temperature is 40°C. 5 times the amount of 30% ethanol was extracted once by heating and refluxing with an electric heating mantle for 1 hour, the extract was collected, and the ethanol was recovered under reduced pressure;

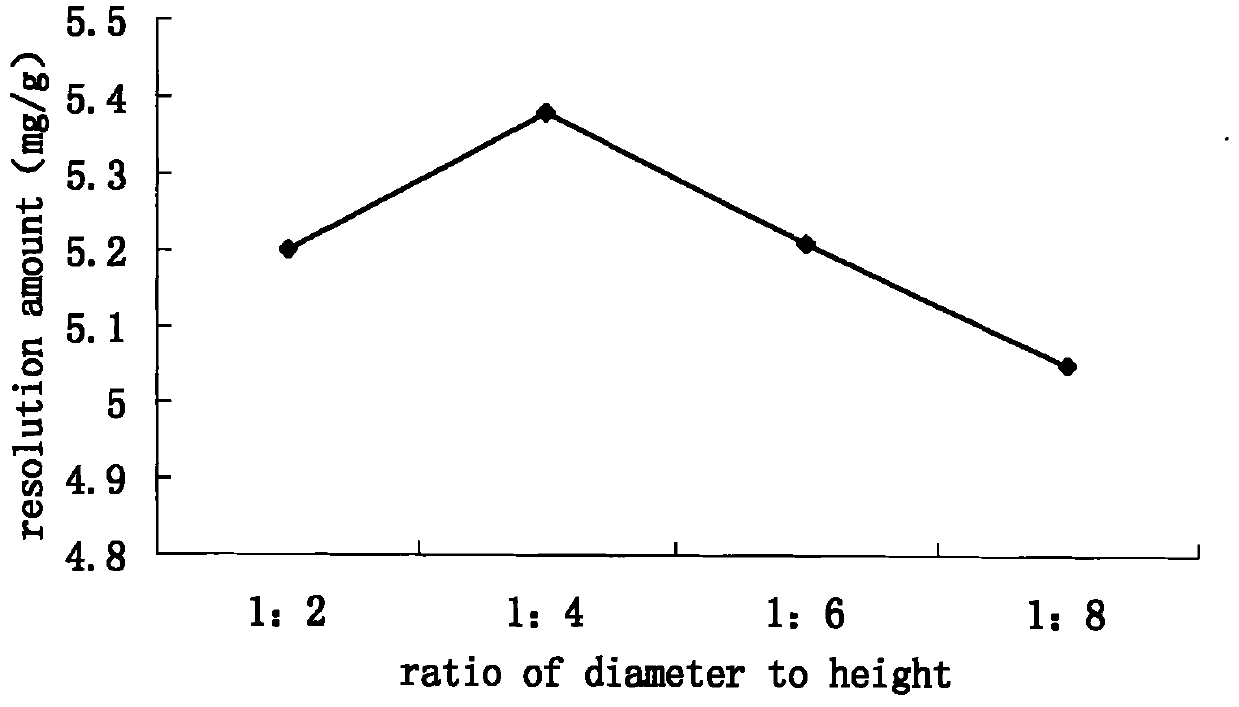

[0053] b. Concentrate the extract from step a to a mass concentration of 0.87g crude drug / mL, and then purify the concentrated solution with HPD100 macroporous resin. The diameter-to-height ratio of the resin bed is 1:4, the sample loading time is 1h, and the flow rate of the effluent is controlled. 3BV / h, let it stand for 2h, let it fully absorb, wash the resin bed with 1BV of pure water, the flow rate of water washing is 1BV / h, remove the part and impurities that are not adsorbed by the resin, elute with 80% ethanol with a concentration of 3BV, and the flow rate is 1BV / h;

[0054]...

Embodiment 2

[0056] a. Crush the chickpeas, pass through a 50-mesh sieve, take 500g of chickpea flour, add 6# solvent oil, and use a water bath to heat and reflux to degrease. The heating temperature is 55°C. 10 times the amount of 50% ethanol was heated and refluxed for 3 times with an electric heating mantle for 2-3 hours, the extract was collected, and the ethanol was recovered under reduced pressure;

[0057] b. Concentrate the extract from step a to a mass concentration of 0.87g crude drug / mL, and then purify the concentrated solution with HPD300 macroporous resin. The diameter-to-height ratio of the resin bed is 1:4, the sample loading time is 3 hours, and the flow rate of the effluent is controlled. 1BV / h, let it stand for 2h, let it fully absorb, wash the resin bed with 3BV of pure water, the flow rate of water washing is 3BV / h, remove the part that is not adsorbed by the resin and impurities, elute with 1BV of 50% ethanol, the flow rate is 3BV / h;

[0058] c. Collect the ethanol e...

Embodiment 3

[0060] a. Crush the chickpeas, pass through a 40-mesh sieve, take 500g of chickpea flour, add 6# solvent oil, and use a water bath to heat and reflux to degrease at a heating temperature of 70°C. 15 times the amount of 80% ethanol was heated and refluxed with an electric heating mantle to extract 4 times, the time was 3 hours, the extraction temperature was 95°C, the extract was collected, and the ethanol was recovered under reduced pressure;

[0061] b. Concentrate the extract from step a to a mass concentration of 0.87g crude drug / mL, and then purify the concentrated solution with SA-3 macroporous resin. The bed diameter-to-height ratio of the loaded resin is 1:4, and the sample loading time is 6 hours to control the outflow The liquid flow rate is 4BV / h, let it stand for 2h, let it fully absorb, wash the resin bed with 3BV of pure water, the water washing flow rate is 4BV / h, remove the part that is not adsorbed by the resin and impurities, and elute with 4BV of 80% ethanol, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com