Method for preparing fine-grain high-strength high-purity alumina ceramics

A technology of high-purity alumina and alumina ceramics is applied in the technical field of preparing fine-grained, high-strength, and high-purity alumina ceramics and low-temperature pressureless sintering, and can solve the problems of being unsuitable for large-scale industrial production, high cost, and large investment. Achieve the effect of fine grain, lower sintering temperature and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Put 8000g of high-purity alumina ceramic balls and 800g of domestic commercial high-purity alumina powder into the sand mill, then add 1600g of deionized water as the grinding medium, and add 1.6ml of organic dispersant DOLAPIX CE 64 [by Sima Chemical Co., Ltd. Provided by the company], 4g inorganic dispersant (NH 4 ) 2 SO 4 , 0.4g of sintering aid MgO, wet grinding for 3 hours; put the ground slurry in a 90°C oven, and dry for 24 hours; pass through a 200-mesh nylon sieve, and then put it in a muffle furnace for calcination at 600°C for 2 Hours; after dry pressing and cold isostatic pressing at 200 MPa, the alumina ceramic green body is obtained; the alumina ceramic green body is placed in a muffle furnace and sintered at 1450°C for 2 hours without pressure to obtain alumina Ceramic samples.

[0036] The high-purity alumina ceramic balls used refer to alumina ceramic balls with an alumina content greater than 99.9% and a diameter of 3 mm.

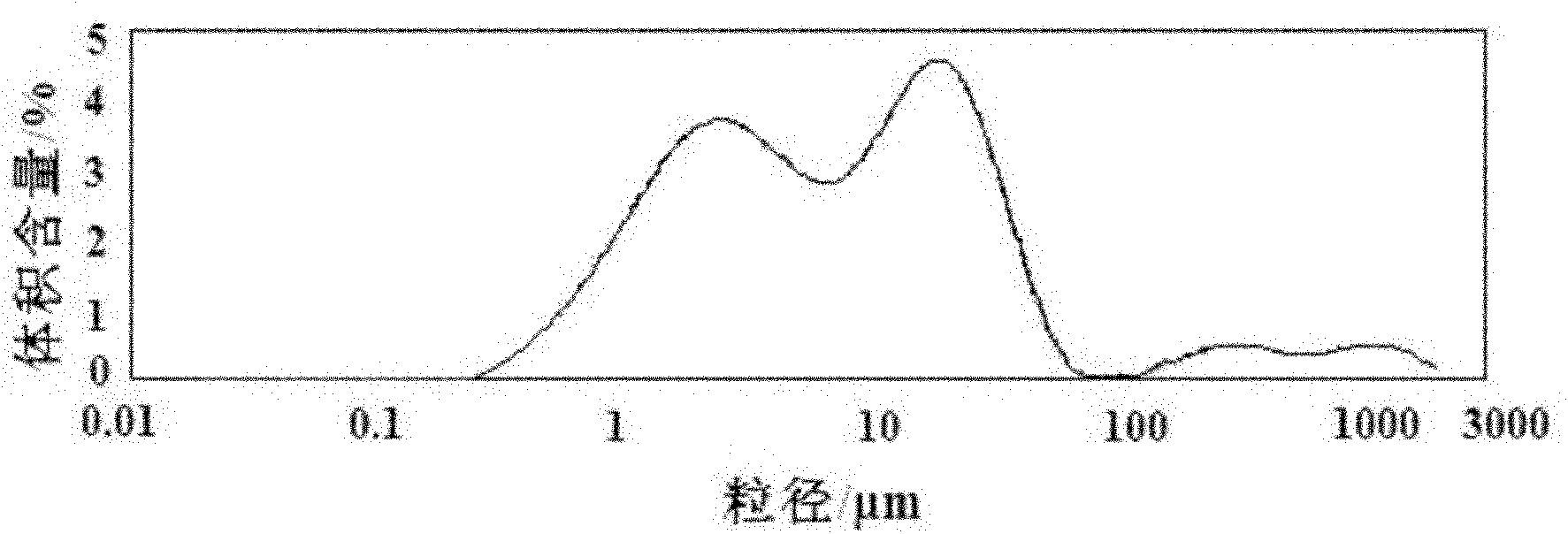

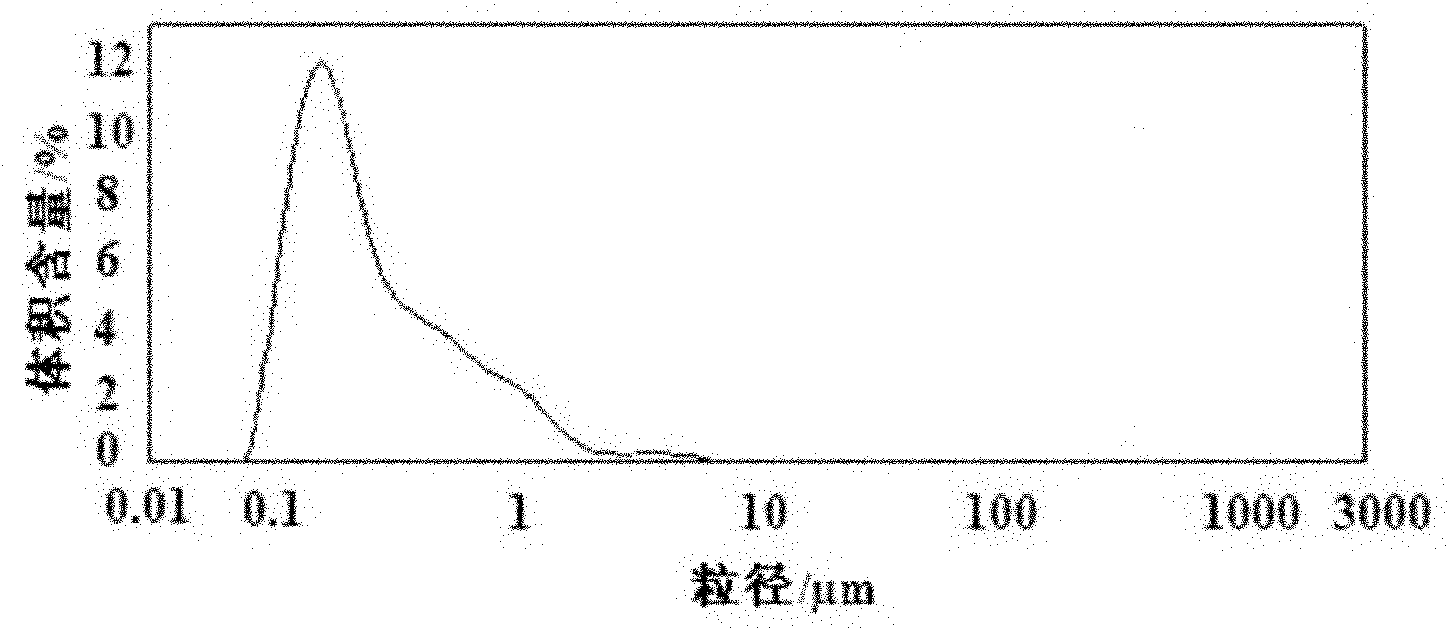

[0037] The domestic comm...

Embodiment 2

[0050] The only difference between this example and Example 1 is that the alumina ceramic green body is placed in a muffle furnace and subjected to pressureless sintering at 1500° C. for 2 hours to obtain an alumina ceramic sample.

[0051] The rest of the content is exactly the same as described in Example 1.

[0052] The present invention also tested the relative density, flexural strength and Vickers hardness of the alumina ceramic samples prepared in this example according to the test method described in Example 1, and the test results are shown in Table 2.

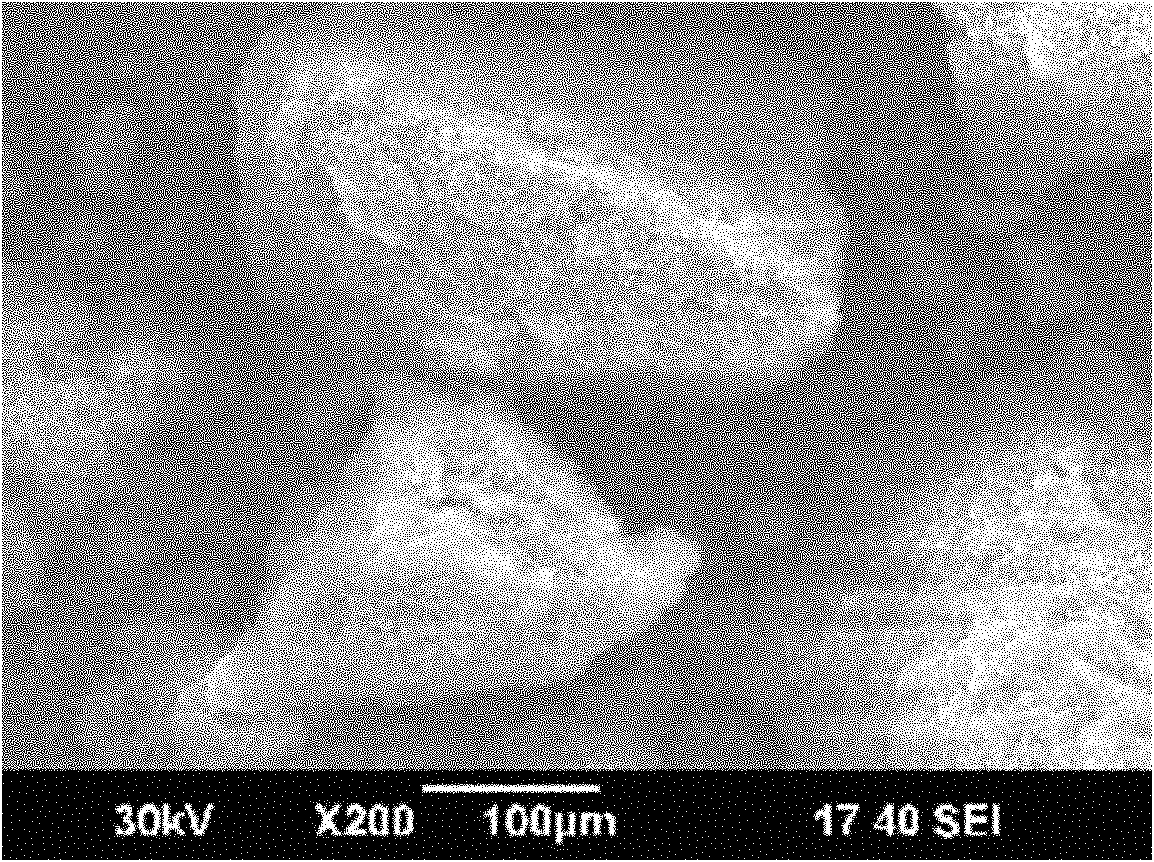

[0053] The cross-sectional morphology of the alumina ceramic sample test strip prepared in this embodiment is shown in Figure 6 shown by Figure 6 It can be seen that the density of the alumina ceramics prepared in this example is higher than that of the alumina ceramics prepared in Example 1, but the grain size is slightly larger, about 3 μm.

Embodiment 3

[0055] The only difference between this example and Example 1 is that the alumina ceramic green body is placed in a muffle furnace and subjected to pressureless sintering at 1550° C. for 2 hours to obtain an alumina ceramic sample.

[0056] The rest of the content is exactly the same as described in Example 1.

[0057] The present invention also tested the relative density, flexural strength and Vickers hardness of the alumina ceramic samples prepared in this example according to the test method described in Example 1, and the test results are shown in Table 2.

[0058] The cross-sectional morphology of the alumina ceramic sample test strip prepared in this embodiment is shown in Figure 7 shown by Figure 7 It can be seen that the density of the alumina ceramics prepared in this example is significantly higher than that of the alumina ceramics prepared in Example 1, but the grain size is significantly larger, reaching about 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com