Fuel with high cleanness

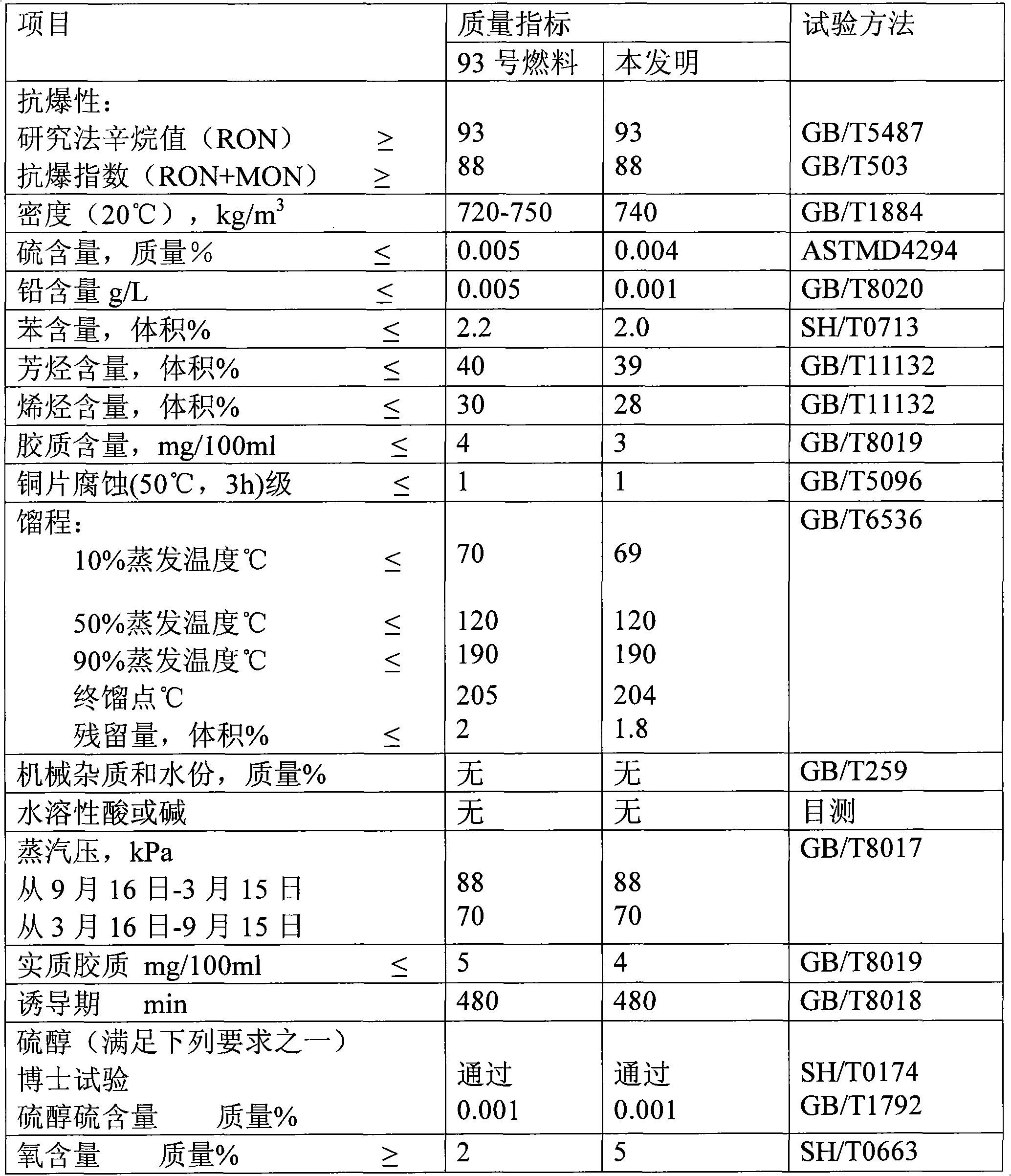

A technology for clean fuels and aromatic hydrocarbons, applied in the field of environmentally friendly fuels and cleanliness, can solve the problems of complex preparation and complex components, and achieve the effect of clean fuel system, good anti-knock performance and good acceleration performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of methanol etherification solution

[0022] Methanol is mixed with the C4 fraction of the refinery and the raffinate of the cracked C5 fraction (the raffinate obtained from the C5 separation device of Lanzhou Xinlan Petrochemical Co., Ltd.), the quality of the C4 fraction and the C5 raffinate of the refinery The ratio is 1: 1, and each contains about 50% by mass of mono-olefins. The molar ratio of methanol to the mono-olefins in C4C5 is 1: 1. After the mixed solution is heated, it is sent into the etherification reactor, and the etherification reaction The etherification catalyst XY-15M type is installed in the device, and the catalyst XY-15M type is produced by Lanzhou Xinyou Petrochemical Co., Ltd., and the liquid phase volume space velocity of methanol is 0.2h -1 , the etherification temperature is 145° C., and the reaction pressure is 0.5 MPa. The etherification reaction occurs in the etherification reactor, and the temperature is lowered to room te...

Embodiment 2

[0027] (1) Preparation of methanol etherification solution

[0028] The preparation of the methanol etherified solution is the same as in the examples.

[0029] (2) blending high clean fuel

[0030] Based on the mass percent of the prepared high-clean fuel, the obtained methanol etherification liquid, crude C9 aromatics (taken from Lanzhou aromatics plant), refinery C4 cut and cracked C5 cut raffinate were mixed with 8%, 36% , 28% and 28% are mixed, and the mixed solution is sent to a homogenizer for homogenization to obtain the high-clean fuel of the present invention.

Embodiment 3

[0032] (1) Preparation of methanol etherification solution

[0033] The preparation of the methanol etherified solution is the same as in the examples.

[0034] (2) blending high clean fuel

[0035] Based on the mass percent of the prepared high-clean fuel, the obtained methanol etherification liquid, crude C9 aromatics (taken from Lanzhou aromatics plant), refinery C4 fraction and cracked C5 fraction raffinate were mixed with 12%, 39% , 24% and 25% are mixed, and the mixed solution is sent to a homogenizer for homogenization to obtain the high-clean fuel of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com