Method for implementing flip-chip soldering of solder during soldering in groove

An undercut and solder technology, applied in the field of microelectronic packaging, can solve problems such as hidden dangers in reliability, and achieve the effect of preventing short-circuiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The process method of solder undercut welding provided by the invention, concrete steps are:

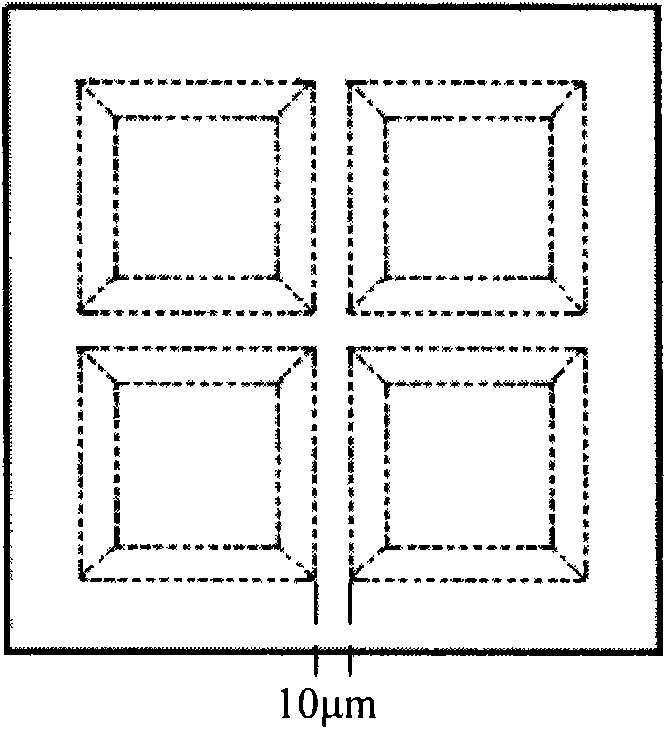

[0029] ①Use an N-type silicon wafer with a thickness of 400-600 μm as the upside-down welding substrate, and use a TMAH solution with a concentration of 25% on the substrate to perform wet etching to form a corrosion opening. The corrosion opening is in the shape of a chute, and the gap between adjacent chute The distance is 10 μm, the inclination angle of the side wall of the chute is 54.7°, the size of the corrosion opening is 64×64 μm, and the depth is 20 μm ( figure 2 );

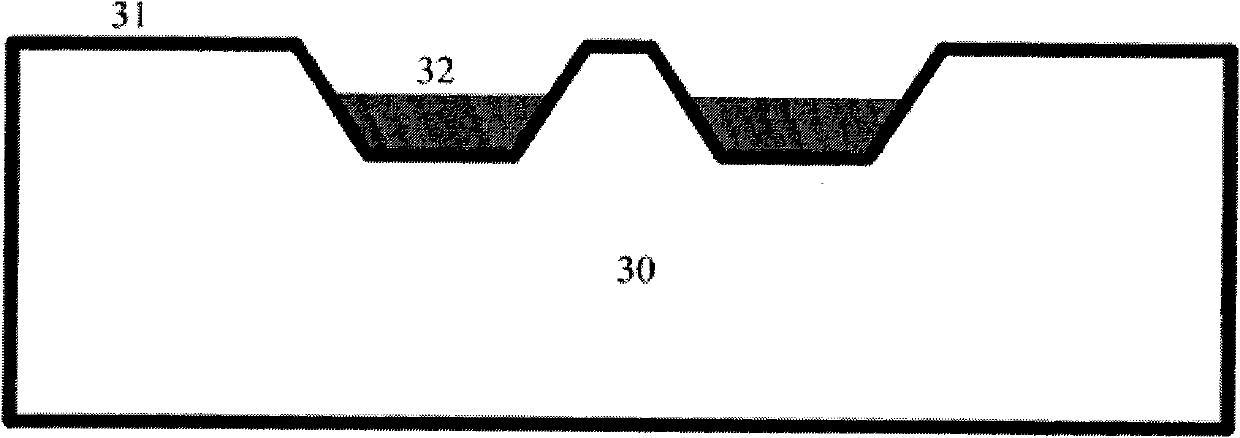

[0030] ② Using the full additive process, make copper pads in the chute ( image 3 )

[0031] a) firstly sputtering a TiW / Cu seed layer on the upper surface of the substrate after etching the opening and passivating in step ①;

[0032] b) glue spraying and photolithography, remove the photoresist at the bottom of the chute, and keep the photoresist on the sidewall of the chute and the periphery of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com