Magnesium alloy grain refiner and grain refined magnesium alloy and preparation method of thereof

A grain refiner and grain refinement technology, applied in the field of magnesium alloy grain refiner and grain refiner magnesium alloy and its preparation, can solve the problem of unstable magnesium alloy grain refinement, alloy Composition fluctuations, loss of activity, etc., to achieve stable grain refinement, high grain refinement efficiency, and content control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

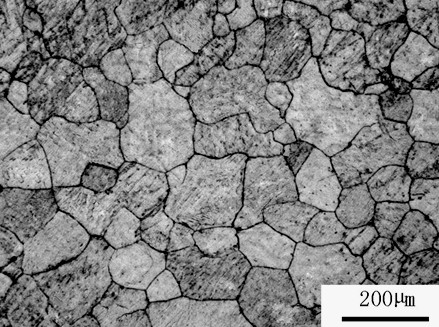

[0045] Example 1 Preparation of magnesium alloy without adding grain refiner

[0046] This example serves as a blank control example without adding a grain refiner.

[0047] The following formula is adopted, and it consists of the following components in terms of mass percentage: Al: 1.35%; Mn, Fe, Si, Ni, Cu, Na are less than 0.30%; Mg: the balance. Melting is carried out in a vacuum induction melting furnace, and pure magnesium and pure aluminum are put into a low-carbon steel crucible according to the formula. Before smelting, evacuate the furnace to a vacuum state, then pass in argon gas, and then start smelting. After the alloy is completely melted, keep it at 720°C for 30 minutes, and pass in argon gas for stirring, so that the added raw materials are fully alloyed.

[0048]Clean up the iron mold with an inner diameter of 85mm and a height of 350mm, and preheat it to 150°C and keep it warm for 20 minutes to make the temperature of the entire iron mold even. Then, the a...

Embodiment 2

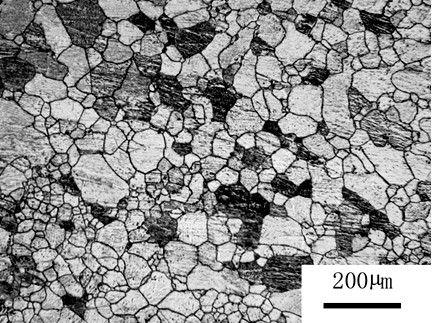

[0050] Example 2 Preparation of Magnesium Alloy Added with Grain Refining Agent

[0051] The following formula is adopted, and it is composed of the following components in terms of mass percentage: Al: 1.35%; Ca: 1.0%; Mn, Fe, Si, Ni, Cu, Na are less than 0.30%; Mg: the balance. Melting is carried out in a vacuum induction melting furnace, and pure magnesium and Mg-Ca master alloy are put into a low-carbon steel crucible according to the formula amount. Before smelting, evacuate the furnace to a vacuum state, then pass in argon gas, and then start smelting. After the alloy is completely melted, add the formula amount of pure Al, keep it at 720°C for 30 minutes, and pass in argon gas for stirring, so that the added The raw materials are fully alloyed.

[0052] Clean up the iron mold with an inner diameter of 85mm and a height of 350mm, and preheat it to 150°C and keep it warm for 20 minutes to make the temperature of the entire iron mold even. Then, it was completely melted,...

Embodiment 3

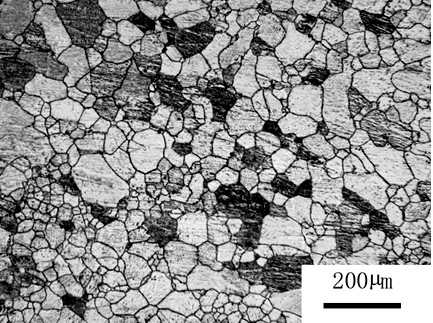

[0055] Example 3 Preparation of Magnesium Alloy Added with Grain Refining Agent

[0056] The following formula is adopted, and it is composed of the following components in terms of mass percentage: Al: 3.0%; Ca: 2.0%; Mn, Fe, Si, Ni, Cu, Na are less than 0.30%; Mg: balance; melting in vacuum induction melting In the furnace, the pure Mg and the Mg-Ca master alloy are put into the low carbon steel crucible according to the corresponding addition amount. Before smelting, evacuate the furnace to a vacuum state, then pass in argon gas, and then start smelting. After the alloy is completely melted, add pure aluminum according to the proportion, keep it at 720°C for 30 minutes, and pass in argon gas for stirring, so that the added The raw materials are fully alloyed.

[0057] Clean up the iron mold with an inner diameter of 85mm and a height of 350mm, and preheat it to 200°C and keep it warm for 20 minutes to make the temperature of the entire iron mold uniform. Then, the alloy m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com