Preparation method of silver nanoparticle lattice with wide plasmon resonant frequency regulation range

A technology of plasmon resonance and silver nanoparticles, which is applied in the field of preparation of silver nanoparticle lattices, can solve the problems of lack of effective and general methods and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

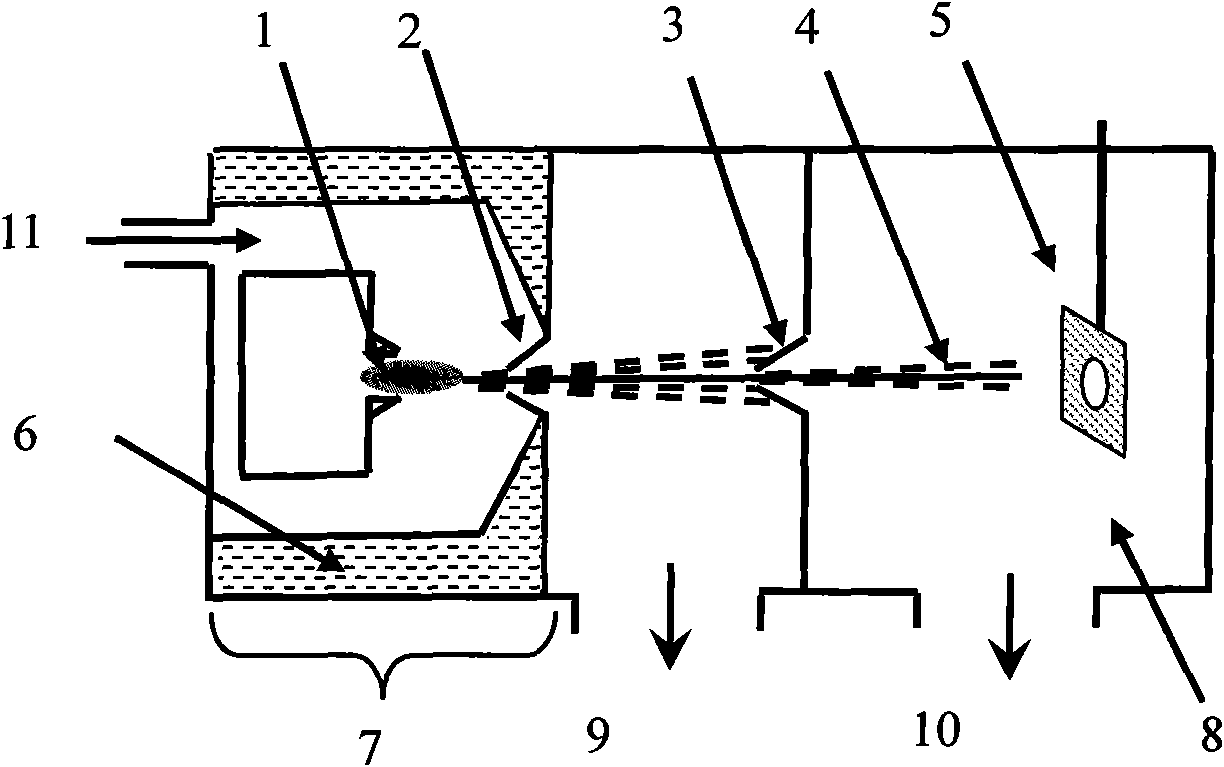

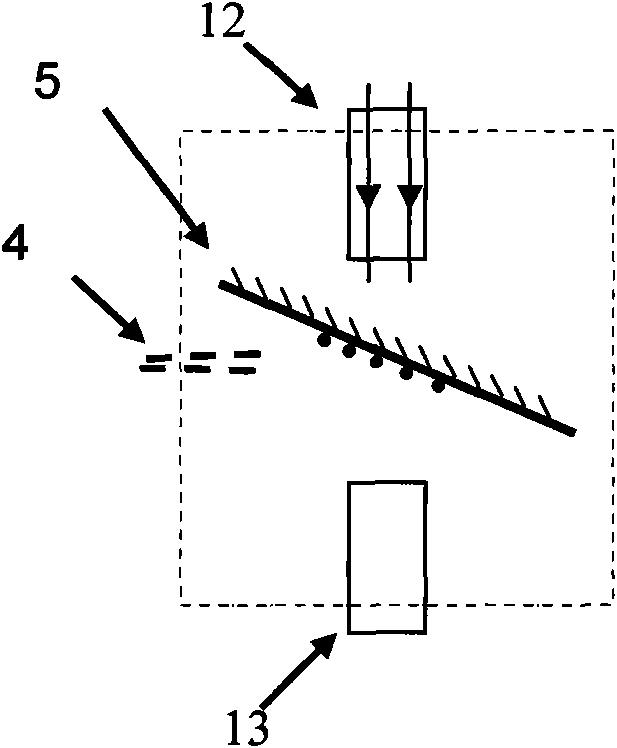

[0042] (1) Cover the surface of the quartz glass substrate with a uniform square film film, with a film thickness of 8-15 nanometers, smear 704 vacuum silicone rubber at the four corners of the substrate to fix the substrate on the rotatable substrate seat 5;

[0043](2) the substrate holder 5 with the substrate is fixedly installed in the high vacuum deposition chamber 8 of the nanoparticle beam deposition system by screws, so that the substrate on the substrate holder 5 is in the center of the silver nanoparticle beam 4;

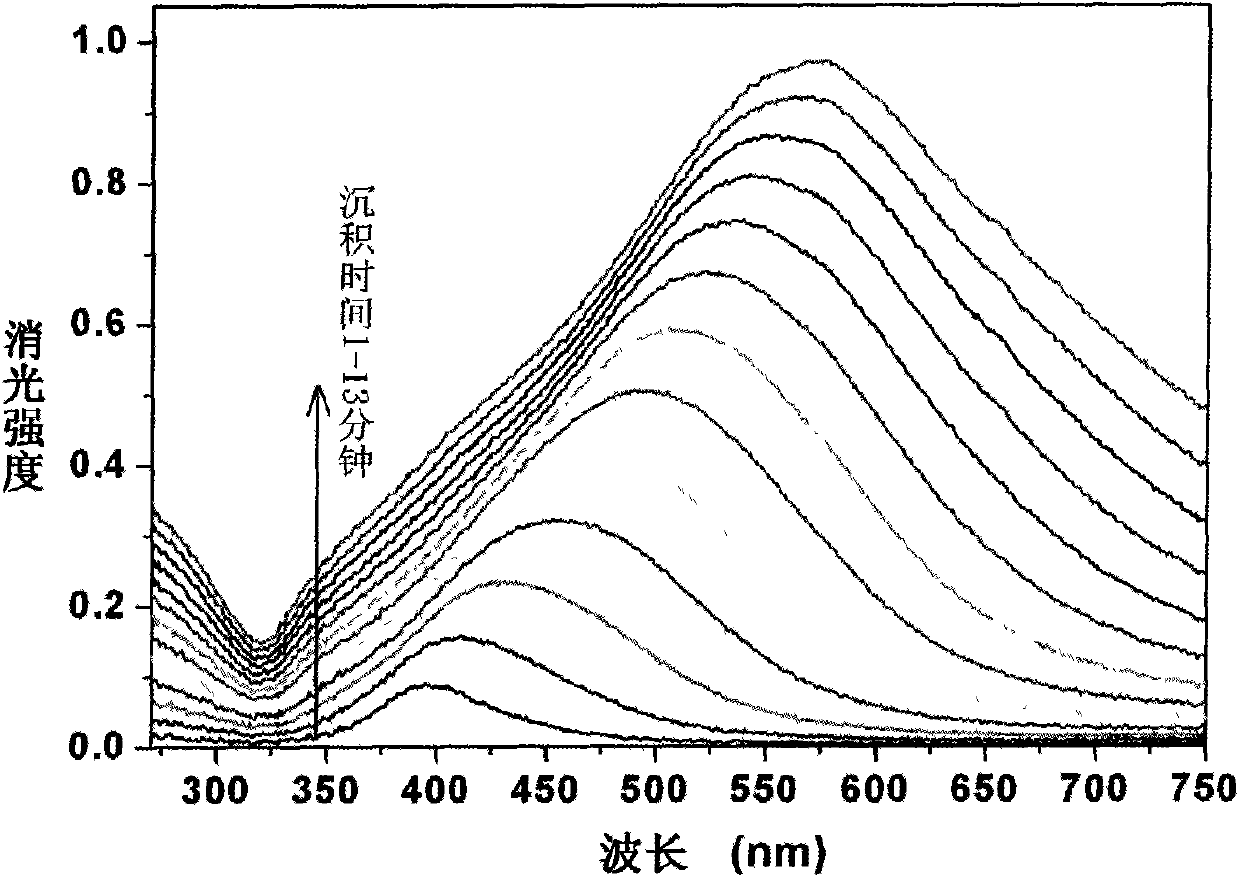

[0044] (3) Utilize the pumping system Rhodes pump 9 and the molecular pump 10 to vacuumize the deposition chamber 8, and the vacuum degree is 5×10 -5 Pa and from the inert gas inlet 11 to the condensing chamber 6 of the cluster beam source of the gas phase concentration method, the argon gas of 150 Pa is charged. Under this pressure, the atomizer 1 in the cluster beam source 7 of the gas phase concentration method passes through the magnetic Controlled spu...

Embodiment 2

[0047] (1) Cover a layer of uniform collodion film on the surface of the quartz glass substrate, the film thickness is 10-15 nanometers, smear 704 vacuum silicone rubber at the four corners of the substrate to fix the substrate on the rotatable substrate seat 5;

[0048] (2) the substrate holder 5 with the substrate is fixedly installed in the high vacuum deposition chamber 8 of the nanoparticle beam deposition system by screws, so that the substrate on the substrate holder 5 is in the center of the silver nanoparticle beam 4;

[0049] (3) Utilize the exhaust system Rhodes pump 9 and molecular pump 10 to vacuumize the deposition chamber 8, and the vacuum degree is 1×10 -5 Pa and from the inert gas inlet 11 to the condensing chamber 6 of the cluster beam source of the gas phase concentration method, the argon gas of 90 Pa is charged. Under this pressure, the atomizer 1 in the cluster beam source 7 of the gas phase concentration method passes through the magnetic Controlled sput...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com