Foamed rubber plate and manufacturing process thereof

A foamed rubber and sheet technology, used in tracks, ballast layers, buildings, etc., can solve the problems of heavy solid rubber pads, weak shock load resistance, and low cushioning and shock absorption performance, and achieve excellent chemical resistance. Effects of chemical stability, excellent electrical insulation, and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] A foamed rubber sheet, which is prepared from the following components in a proportion by weight: EPDM: 100 parts, DCP: 1.7 parts, S: 0.5 parts, CZ: 0.5 parts, TMTD :0.3 parts, zinc oxide: 3.5 parts, stearic acid: 2.5 parts, antioxidant RD: 1 part, antioxidant 4010NA: 1 part, carbon black N220: 20 parts, carbon black N330: 25 parts, carbon black N660: 25 Parts, plasticizer paraffin oil: 55 parts, blowing agent OBSH: 2.5 parts, petrolatum: 0.5 parts.

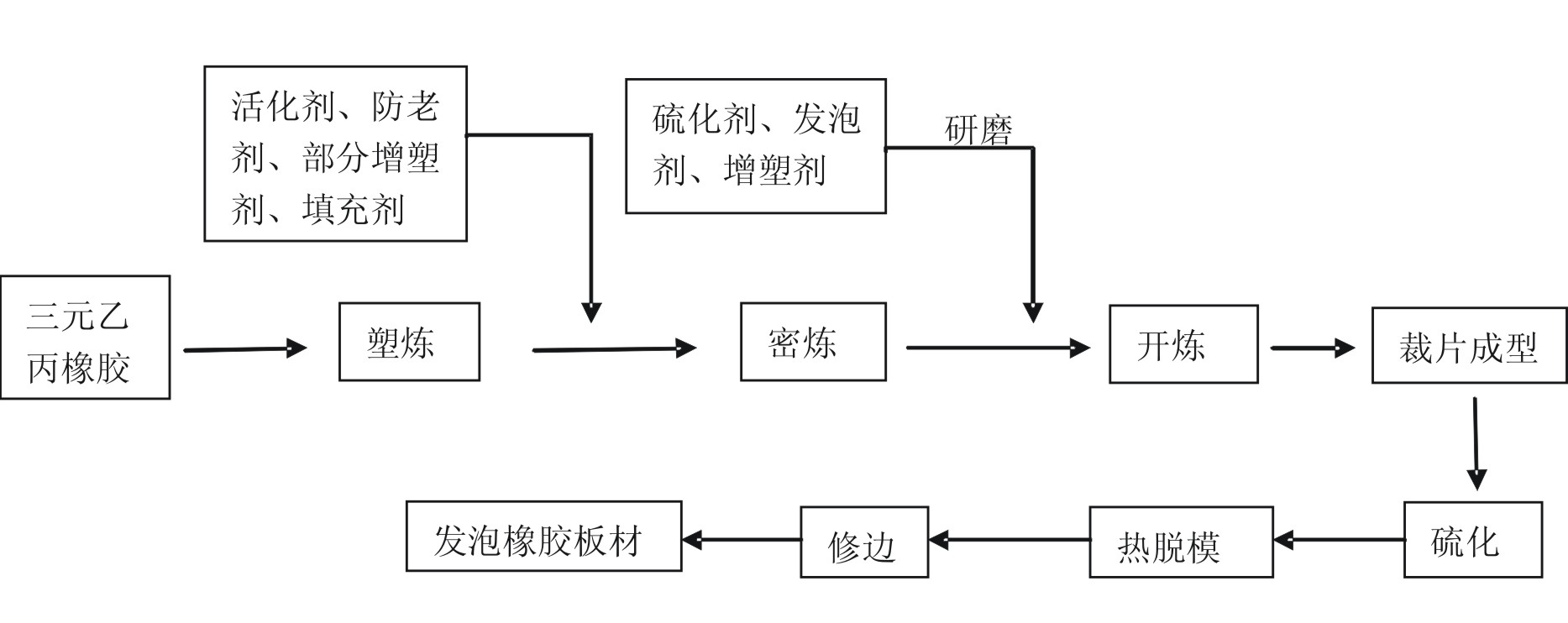

[0101] The above-mentioned preparation method of foam rubber sheet includes the following steps:

[0102] a. Weigh each component according to the above formula and set aside;

[0103] b. Put the EPDM rubber into the internal mixing chamber for 2 minutes for mastication, the mastication temperature is 70±5℃;

[0104] c. Then put the activator into the banbury mixing chamber for 1 minute, the banbury temperature during this process is 75~80℃; then put the antioxidant, some plasticizers, and fillers into the banbury mixing chamber ...

Embodiment 2

[0115] A foamed rubber sheet, which is prepared from the following components in a proportion by weight: EPDM: 100 parts, DCP: 2 parts, S: 1 part, CZ: 1 part, TMTD :0.5 parts, zinc oxide: 4.5 parts, stearic acid: 2 parts, antioxidant RD: 1 part, antioxidant 4010NA: 1.5 parts, carbon black N220: 25 parts, carbon black N330: 30 parts, carbon black N660: 40 Parts, plasticizer paraffin oil: 65 parts, blowing agent OBSH: 3.5 parts, petrolatum: 0.8 parts.

[0116] The preparation method of the foamed rubber sheet is as described in the first embodiment.

Embodiment 3

[0118] A foamed rubber sheet, which is prepared from the following ingredients in parts by weight: EPDM: 100 parts, DCP: 2.5 parts, S: 1.5 parts, CZ: 1.5 parts, TMTD :1 part, zinc oxide: 4.5 parts, stearic acid: 2.5 parts, antioxidant RD: 1 part, antioxidant 4010NA: 1.5 parts, carbon black N220: 30 parts, carbon black N330: 40 parts, carbon black N660: 50 Parts, plasticizer paraffin oil: 70 parts, blowing agent OBSH: 4 parts, petrolatum: 1 part.

[0119] The preparation method of the foamed rubber sheet is as described in the first embodiment.

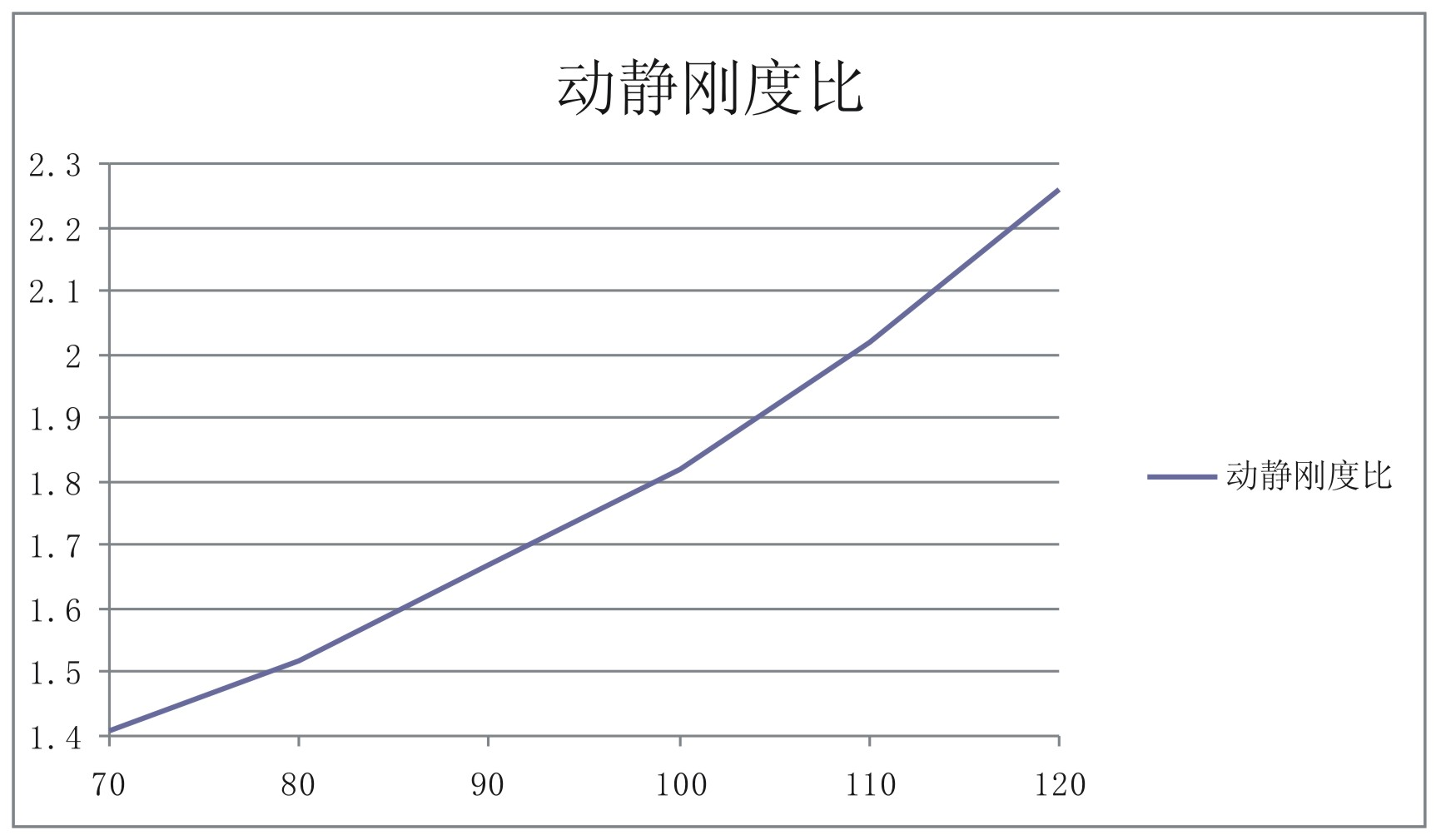

[0120] The physical and mechanical performance detection test and related data of the present invention:

[0121] We sent the foamed rubber sheet products prepared in the above embodiments to the Institute of Metal and Chemistry of the Chinese Academy of Railway Sciences for static stiffness, tensile strength, elongation at break, compression set, hot air aging, qualitative analysis of composition, Water resistance etc. were tested, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com