Multi-wavelength optical fiber sensor based on Fabry-Perot cavity

An optical fiber sensor, multi-wavelength technology, applied in the direction of using optical devices to transmit sensing components, instruments, scientific instruments, etc., can solve the problems of expensive high-speed spectral equipment, limit the upper limit of vibration frequency measurement, etc., to eliminate measurement errors, eliminate Interfere, eliminate the effect of strong light background

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following embodiments will further illustrate the present invention in conjunction with the drawings.

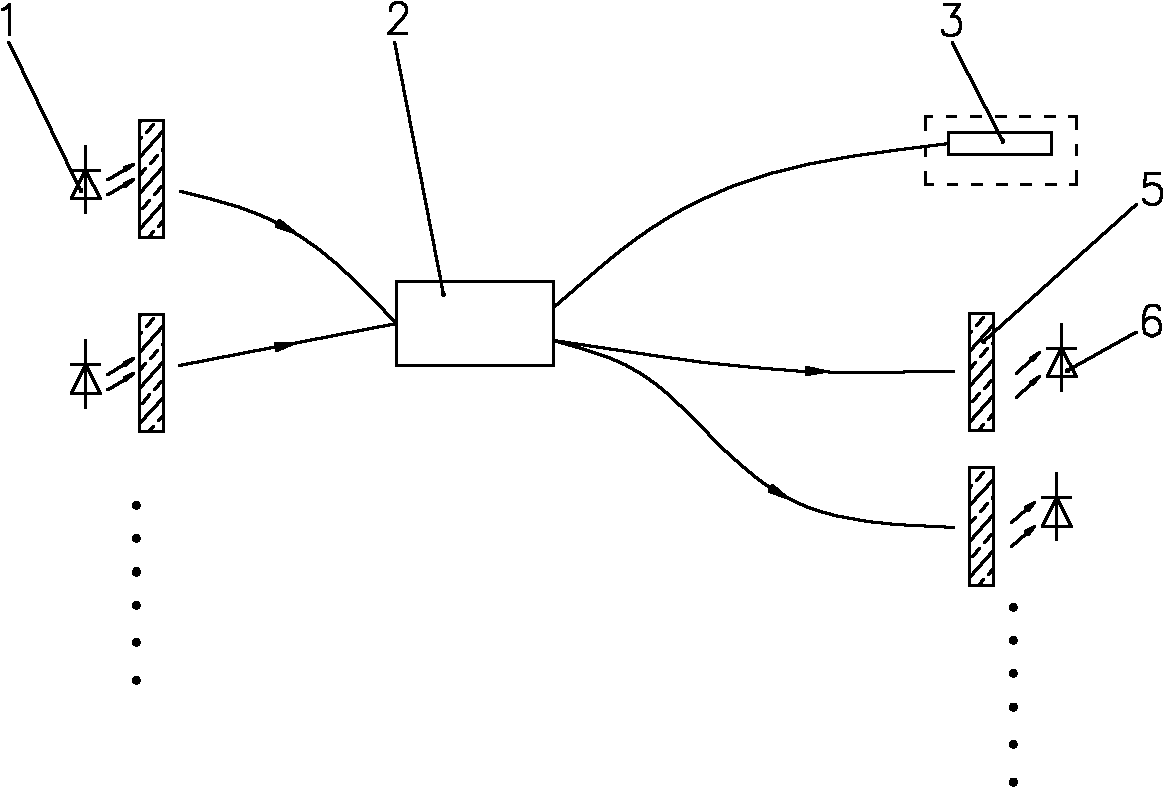

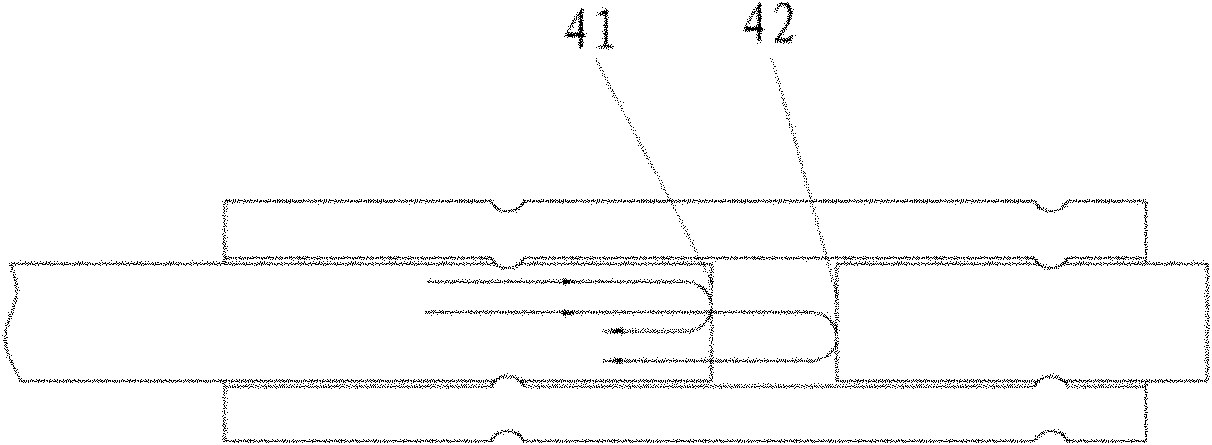

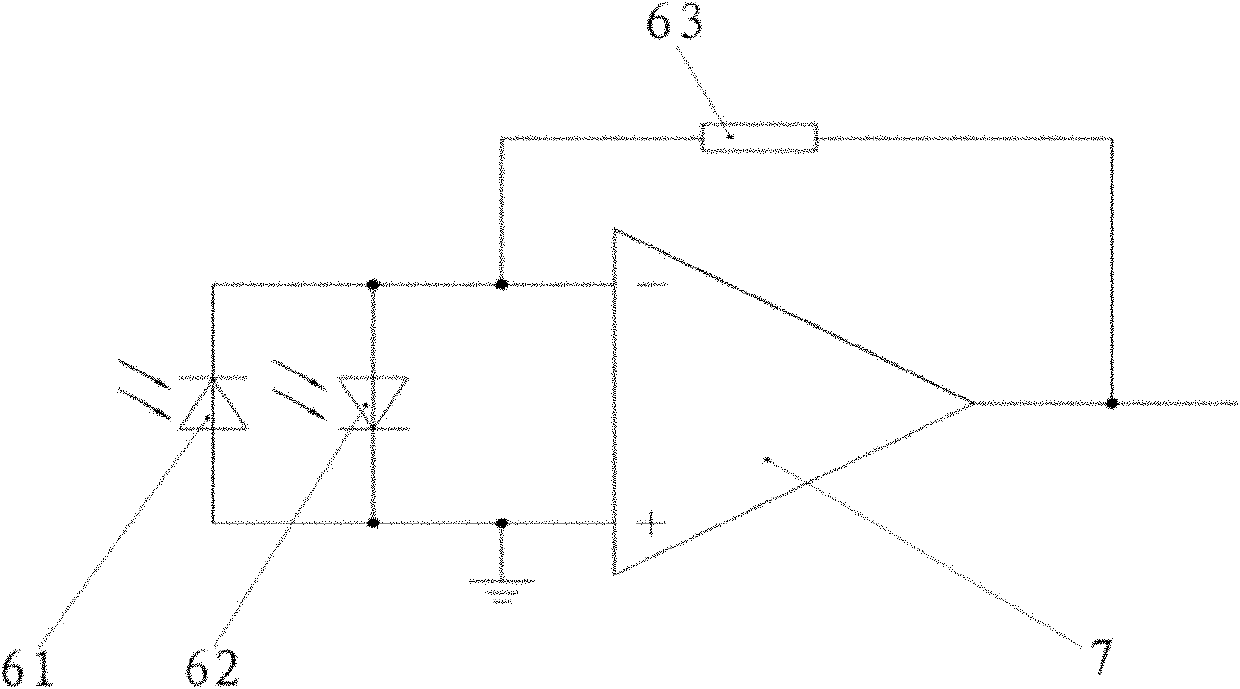

[0021] in figure 1 In, the laser beam emitted by the semiconductor laser 1 enters the optical fiber after being collimated and focused, and the wave function of each wavelength is E n =acos(w n t+δ n ), enter the Fabry-Perot cavity sensing head 3 through the optical fiber broadband coupler 2. Coherent light figure 2 Fresnel reflection occurs at the interface 41, and total reflection occurs at the interface 42. The two reflected lights are superimposed on the interface 41, and the expression is E n =Eb n +Ei n , Where Ei n =ηE n cos(k n z) represents the interference part of the reflected light, z is the amount of cavity length change, η is determined by the coupling efficiency, interference contrast, and cavity length loss, k n Mainly determined by the wavelength, Eb n It is the part where no interference occurs. When the external environment pressure, temperature, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com