HgCdTe infrared photoconductive detector with reference element structure

A reference element and detector technology, applied in the field of photodetectors, can solve the problem that mercury cadmium telluride infrared detectors cannot measure the temperature of high-speed moving objects, and achieve the effects of fast response speed and simplified circuit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

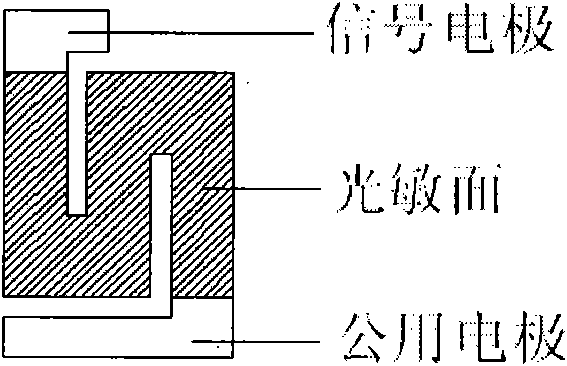

Image

Examples

Embodiment Construction

[0014] The specific implementation of the present invention will be described in detail below with the structure of a 10-element linear mercury cadmium telluride photoelectric device:

[0015] 1) The conventional process processes the body material HgCdTe to about 10 microns.

[0016] 2) Chemically corroding the mercury cadmium telluride sheet, and then using anodic oxidation to form a passivation layer.

[0017] 3) The mercury cadmium telluride chip obtained in the second step is subjected to positive resist photolithography, and then ion etching for 180 minutes to obtain a device pattern.

[0018] 4) Dissolving the positive resist with ethanol, and then successively using HF etching solution and 3% bromomethanol solution to etch the HgCdTe surface to obtain a HgCdTe chip with less damage to the surface brightness.

[0019] 5) Conventional anodic oxidation to form a passivation film.

[0020] 6) Positive photolithography covers the photosensitive surface, and chromium gold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com