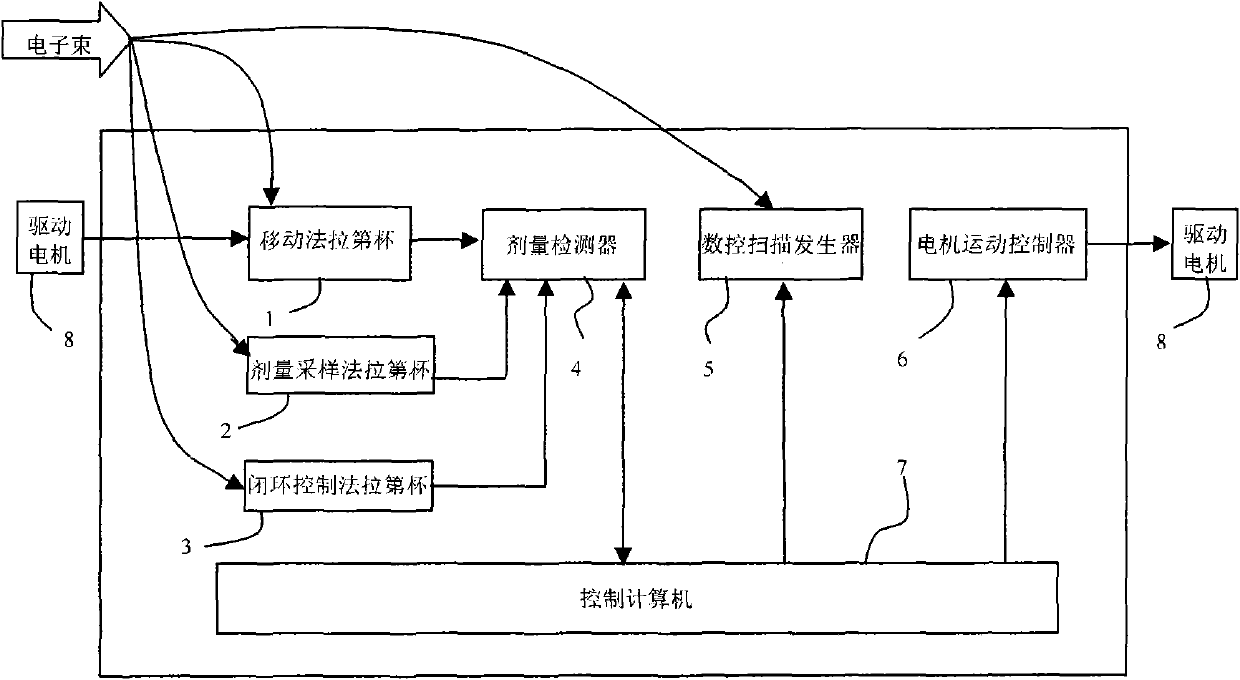

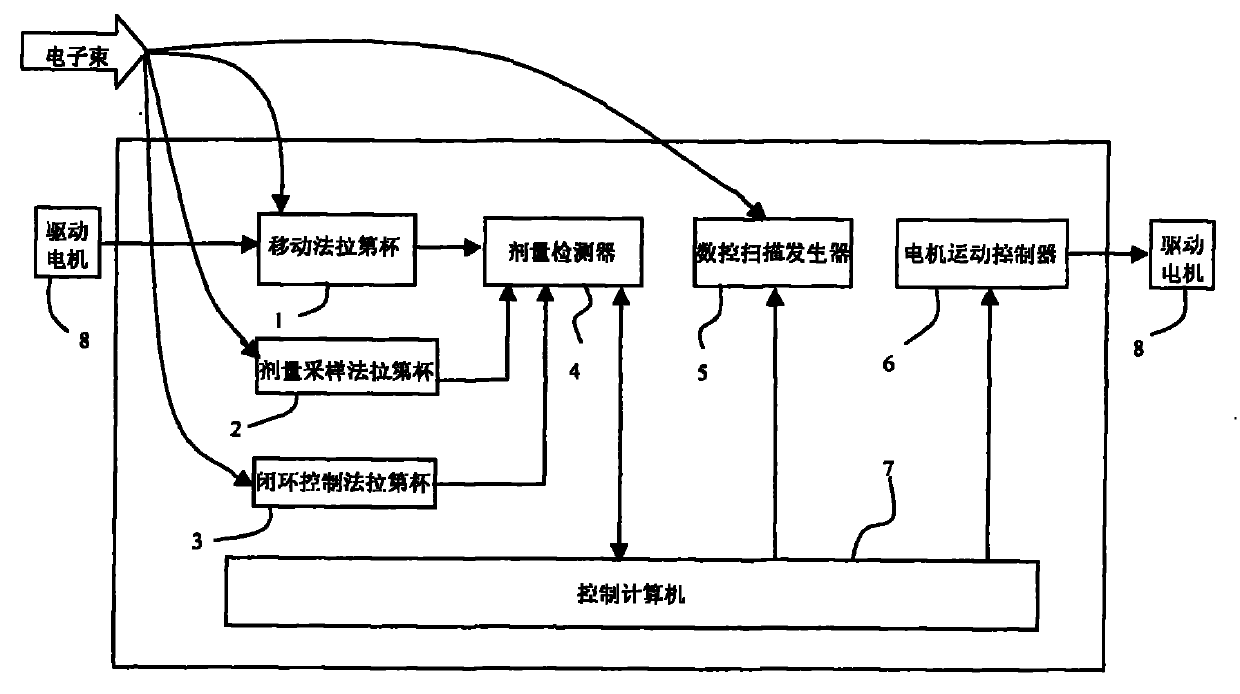

Calibration system and calibration method for dual-Faraday cup measuring ratios of ion implantation machine

A Faraday cup and ratio technology, which is used in ion implantation plating, semiconductor/solid-state device testing/measurement, vacuum evaporation plating, etc., can solve the problems of ion beam implantation doping, etc. Guaranteed effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] According to the above method, a set of correction data of the measurement ratio of double Faraday cups is recorded, as shown in Table 1 below. In an embodiment, the ion implanter implants B + Ions, the implantation energy is set to 50keV, and the ion beam current is set between 1mA and 5mA. First, the ion source system and beamline system are automatically adjusted, and the required ion beam current is set, and then the uniformity optimization program is started to make the scanning ion The uniformity of the beam along the horizontal direction meets the requirements; under the set ion beam flow (the implantation dose will also change), the implantation dose at the center of the silicon wafer is measured with a moving Faraday cup, and the implantation dose at the edge of the silicon wafer is measured with a closed-loop control Faraday cup. Find the ratio and list it in the table.

[0043] Table 1 lists the ratio values under different ion implantation doses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com