Poly(meth)acrylaimide having improved optical and color properties, particularly under thermal load

A technology of imidization and color, applied in the field of thermoplastics, which can solve the problems of deterioration of optical properties, loss of transparency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

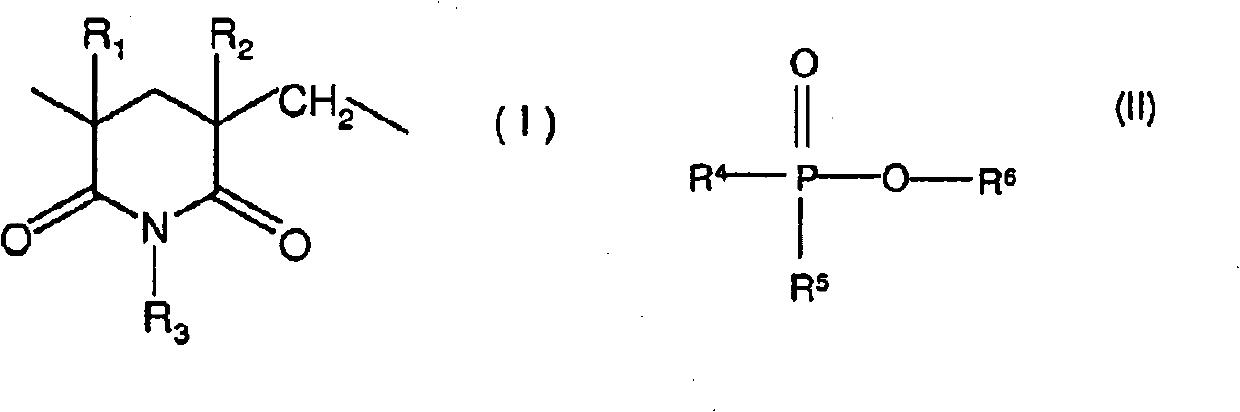

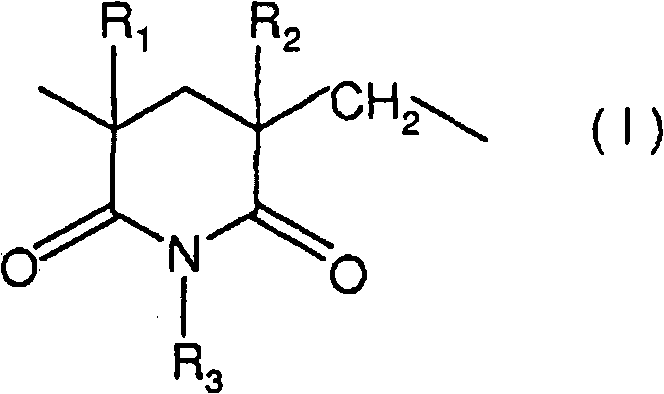

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1 (the comparative example that does not add stabilizing agent)

[0067] Polymer analogous transformation reactions, i.e. acyl imidization. 10 kg of PMMA molding compound per hour were introduced into the reactive extruder. In the first part of the mixing zone, there is a feed point for the liquid. 3000 g methylamine / h were fed to this feed point as reaction medium. The average reaction time was 5 minutes at a temperature of 250°C. After the reaction is complete, the reaction mixture is depressurized in the vented extruder, gaseous and volatile fractions are removed, and finally strands are extruded, cooled and cut into pellets.

[0068] The resulting product was injection molded on an Arburg 221 injection molding machine to a series of 65 x 40 x 3 mm test pieces, which were determined for yellowness index, clarity and haze according to DIN 6167 and ISO 14782. The Vicat softening temperature determined according to ISO 306 method B 50 is 172.4°C. Four o...

Embodiment 2

[0074] Embodiment 2 (according to the present invention)

[0075] Addition of organic hypophosphite to finished PMMI pellets

[0076] The procedure of Example 1 was repeated, except that a 10.4% (wt%) methanol solution of benzophosphinic acid (BHPS) was added to the downstream vented extruder at a metering rate of 0.2 kg / h. The metering point is selected for addition to the melt which has been cleaned of volatile and devolatilizable constituents. The final concentration of BHPS in the PMMI molding compound was 3000 ppm. According to Example 1, test pieces were prepared from the pellets obtained and a thermal load was applied at 160° C. for a period of 1000 h. The following results are obtained:

[0077] Example

[0078] Table 2: Thermal storage at 160°C (organohypophosphite free acid)

[0079] time [h]

[0080] It can be seen that good clarity, and lower haze and yellowness index can be achieved by the use of benzophosphinic acid. During thermal storag...

Embodiment 3

[0081] Embodiment 3 (according to the present invention)

[0082] Addition of organic hypophosphite to finished PMMI pellets

[0083] The procedure of Example 2 was repeated, except that an 8.4% (weight %) methanol solution of sodium benzophosphinate was added to the downstream vented extruder at a metering rate of 0.2 kg / h. The final concentration of BHPS sodium salt in the PMMI molding compound was 2200 ppm. The following results are obtained:

[0084] Example

[0085] 3

[0086] Table 3: Thermal storage at 160°C (organohypophosphite sodium salt)

[0087] Duration [h]

[0088] It can be seen that good clarity, and lower haze and yellowness index can also be achieved by the use of sodium benzophosphinate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com