Carbon nitride-graphene composite material as well as preparation method and application thereof

A composite material and graphene technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of small specific surface area and low conductivity, so as to increase specific surface area, increase specific capacity, and increase pseudocapacitance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a carbon nitride-graphene composite material, the preparation method is as follows:

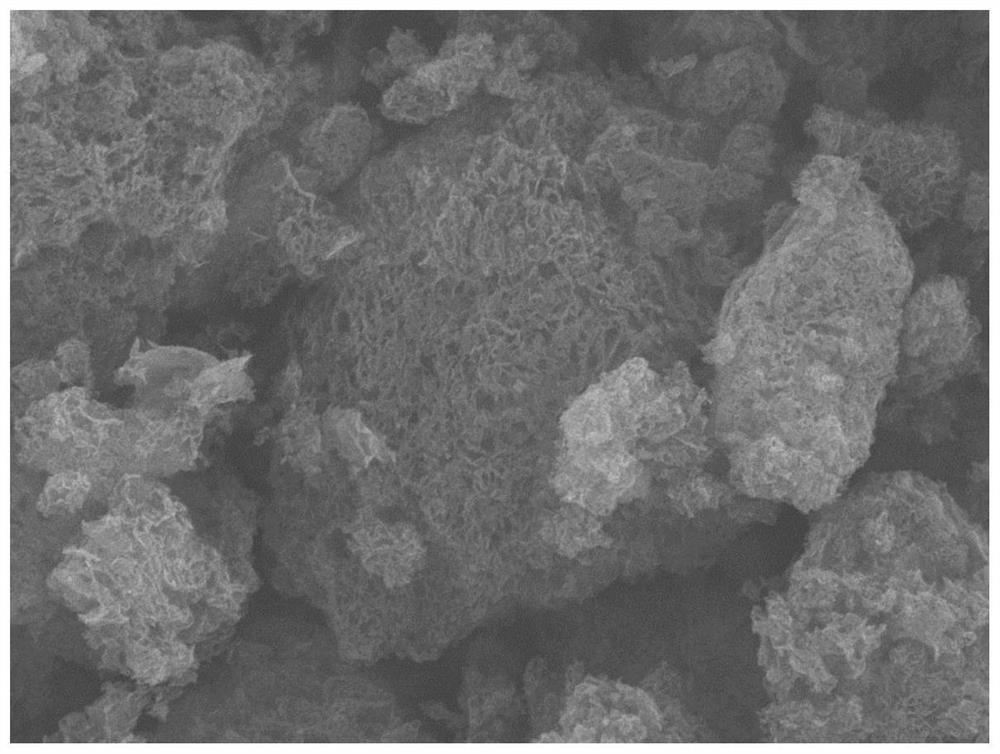

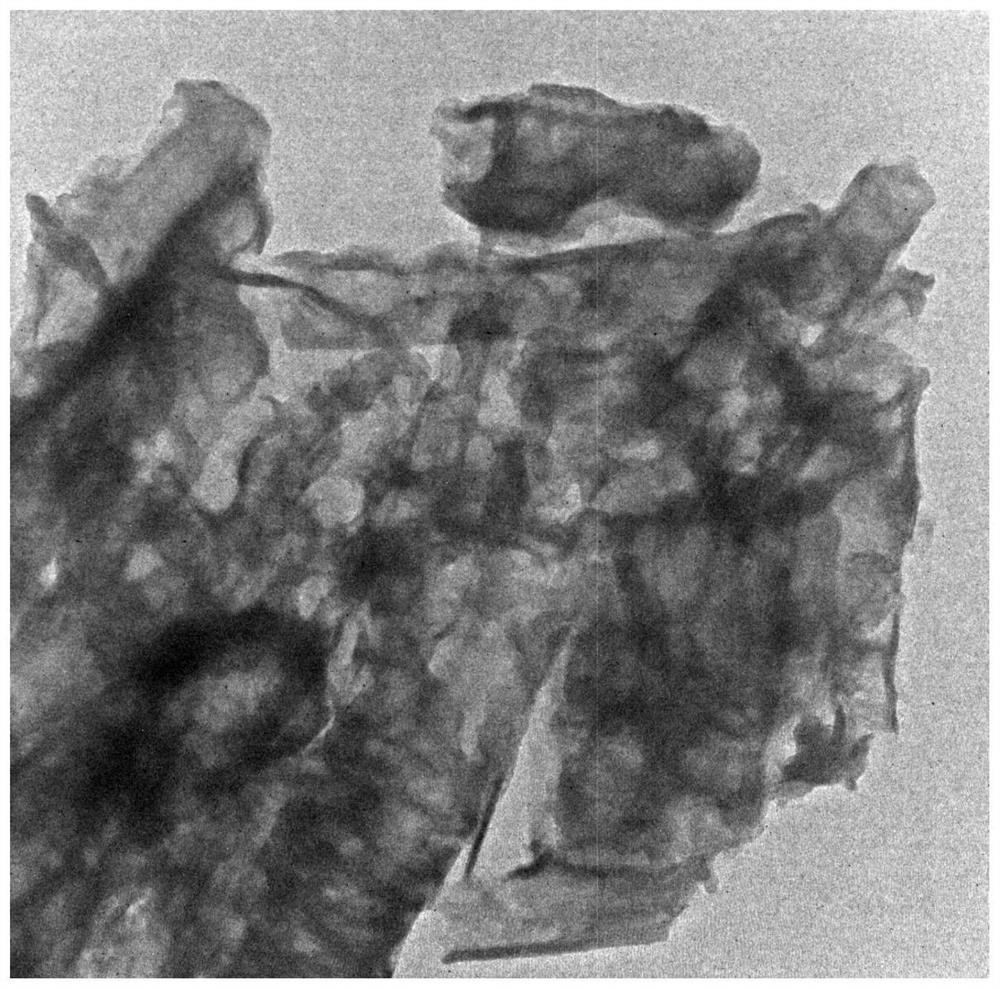

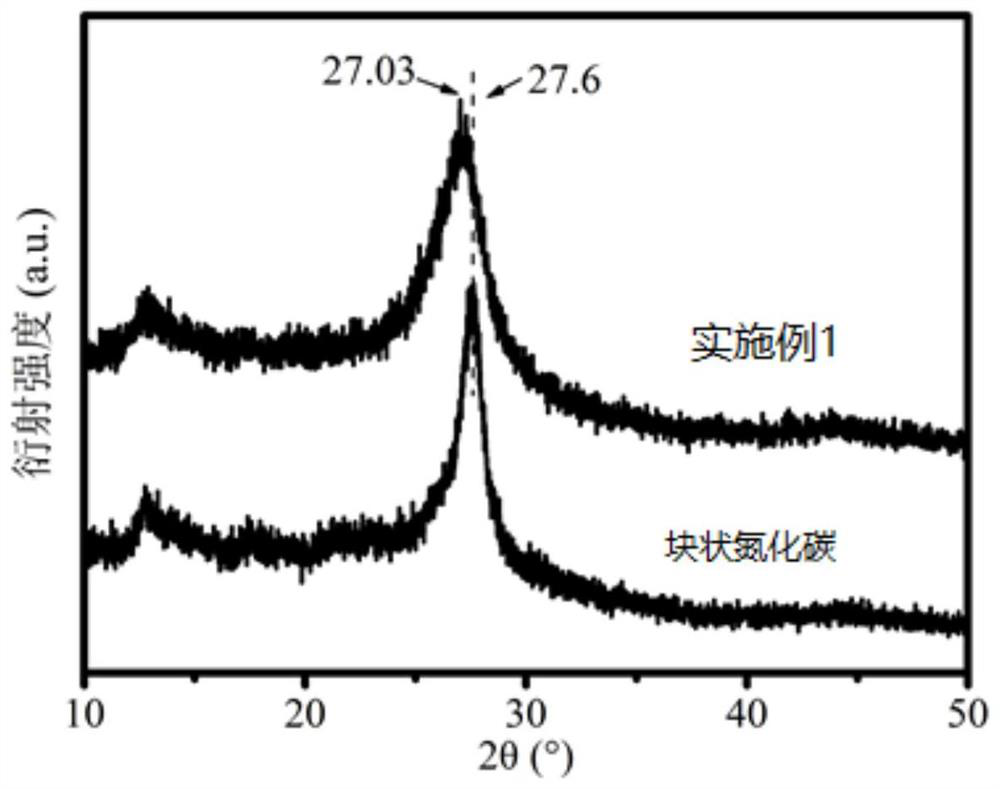

[0047] Step 1: Preparation of sulfur-doped porous honeycomb carbon nitride

[0048] Disperse 1.77g of thiocyanic acid and 3.04g of thiourea in 100mL of distilled water, and mechanically stir for 2h to form a hydrogel-like supramolecular precursor of thiocyanic acid-thiourea. Put the thiocyanic acid-thiourea supramolecular precursor into an oven at 60°C and dry for 24 hours until the thiourea supramolecular precursor becomes a block. The bulk thiocyanic acid-thiourea supramolecular precursor was ground into powder and put into a crucible, and the crucible was placed in a muffle furnace at 600 °C for 1 h, and the heating rate was 5 °C / min. After cooling, the sulfur-doped porous honeycomb carbon nitride was obtained, and its scanning electron microscope picture was as follows: figure 1 shown. Take 0.1 g of the above-mentioned sulfur-doped porous honeycomb carbo...

Embodiment 2

[0052] This embodiment provides a carbon nitride-graphene composite material, the preparation method is as follows:

[0053] Step 1: Preparation of sulfur-doped porous honeycomb carbon nitride

[0054] Disperse 1.77g of thiocyanic acid and 3.42g of thiourea in 100mL of distilled water, and mechanically stir for 2h to form a hydrogel-like supramolecular precursor of thiocyanic acid-thiourea. Put the thiocyanic acid-thiourea supramolecular precursor into an oven at 62°C and dry for 23 hours until the thiocyanic acid-thiourea supramolecular precursor becomes a block. The bulk thiocyanic acid-thiourea supramolecular precursor was ground into powder and put into a crucible, and the crucible was placed in a muffle furnace at 610°C for 0.8h, and the heating rate was 5.5°C / min. After cooling, a sulfur-doped porous honeycomb carbon nitride is obtained. Take 0.12 g of the above-mentioned sulfur-doped porous honeycomb carbon nitride and disperse it in 100 mL of distilled water to prepa...

Embodiment 3

[0058] This embodiment provides a carbon nitride-graphene composite material, the preparation method is as follows:

[0059] Step 1: Preparation of sulfur-doped porous honeycomb carbon nitride

[0060] Disperse 1.77g of thiocyanic acid and 2.66g of thiourea in 100mL of distilled water, and mechanically stir for 2h to form a hydrogel-like supramolecular precursor of thiocyanic acid-thiourea. Put the thiocyanic acid-thiourea supramolecular precursor into an oven at 58°C and dry for 25 hours until the thiourea supramolecular precursor turns into block. The bulk thiocyanic acid-thiourea supramolecular precursor was ground into powder and put into a crucible, and the crucible was placed in a muffle furnace at 590°C for 1.2h, and the heating rate was 4.5°C / min. After cooling, a sulfur-doped porous honeycomb carbon nitride is obtained. Take 0.08 g of the above-mentioned sulfur-doped porous honeycomb carbon nitride and disperse it in 100 mL of distilled water, and configure it into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com