One-dimensional bar barium ferrite and preparation method thereof

A barium ferrite, rod-shaped technology, applied in the field of rod-shaped M-type barium ferrite and cobalt-titanium doped M-type barium ferrite magnetic powder and its preparation, magnetic materials and its preparation, can solve complex process, High production cost and other problems, to achieve the effect of stable process, low cost and shortened heat treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Get x=0, press Fe / Ba=11.6 (molar ratio), weigh a certain amount of BaCl 2 and γ-FeOOH. BaCl 2 Dissolve it with deionized water and move it into the reactor, then add γ-FeOOH to BaCl 2in the aqueous solution and stir evenly, and control the temperature in the reactor to 50°C; press Ba 2+ / CO 3 2- =1:1 (molar ratio) Weigh Na 2 CO 3 , after being formulated into an aqueous solution, add it dropwise to the reactor, and the dropping time is controlled to be 8 hours; after the dropwise addition, the product obtained is left to stand for 12 hours; the product after standing is washed with water until the pH of the filtrate is 7.0, and suction filtered, The precursor was obtained after drying at 50°C. The precursor was fired at 1000 °C for 3 hours. After roasting, grind to obtain the final product.

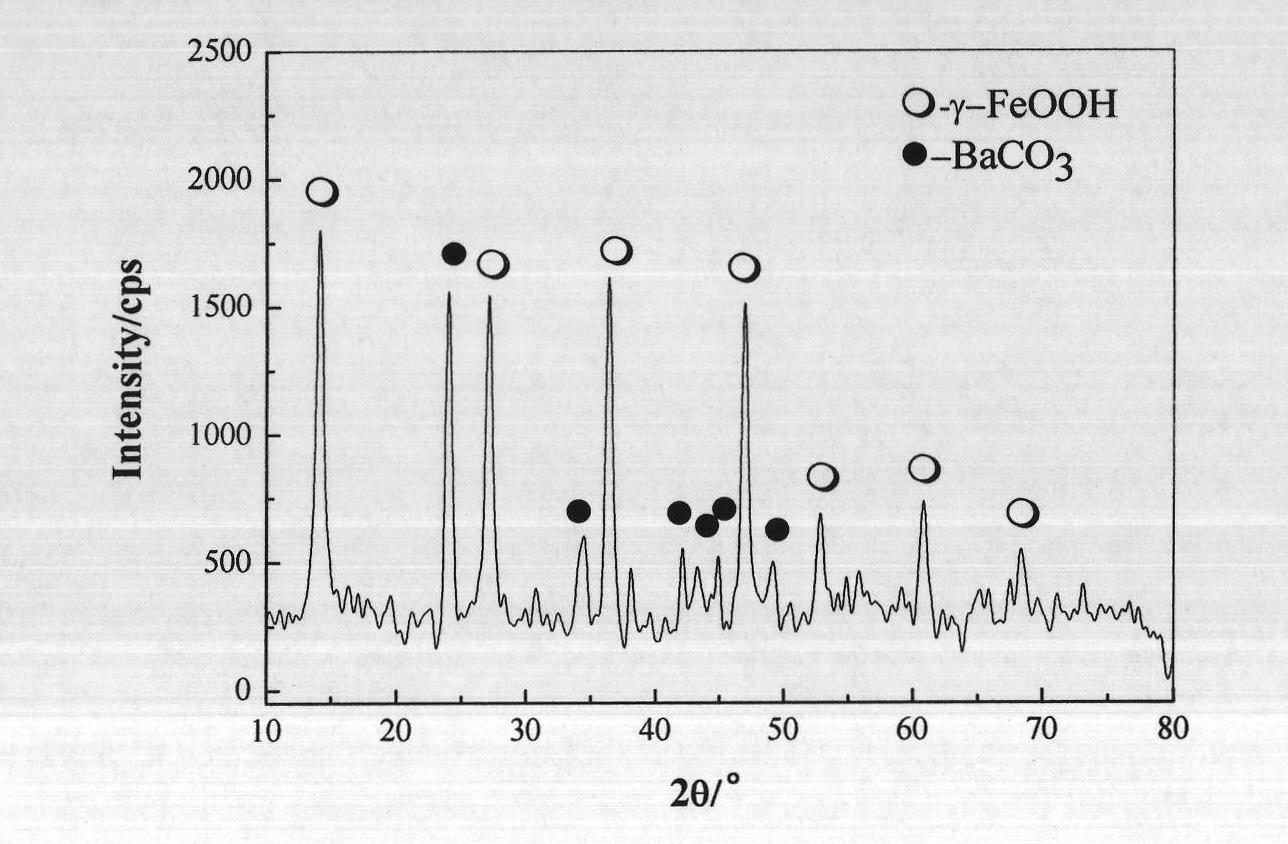

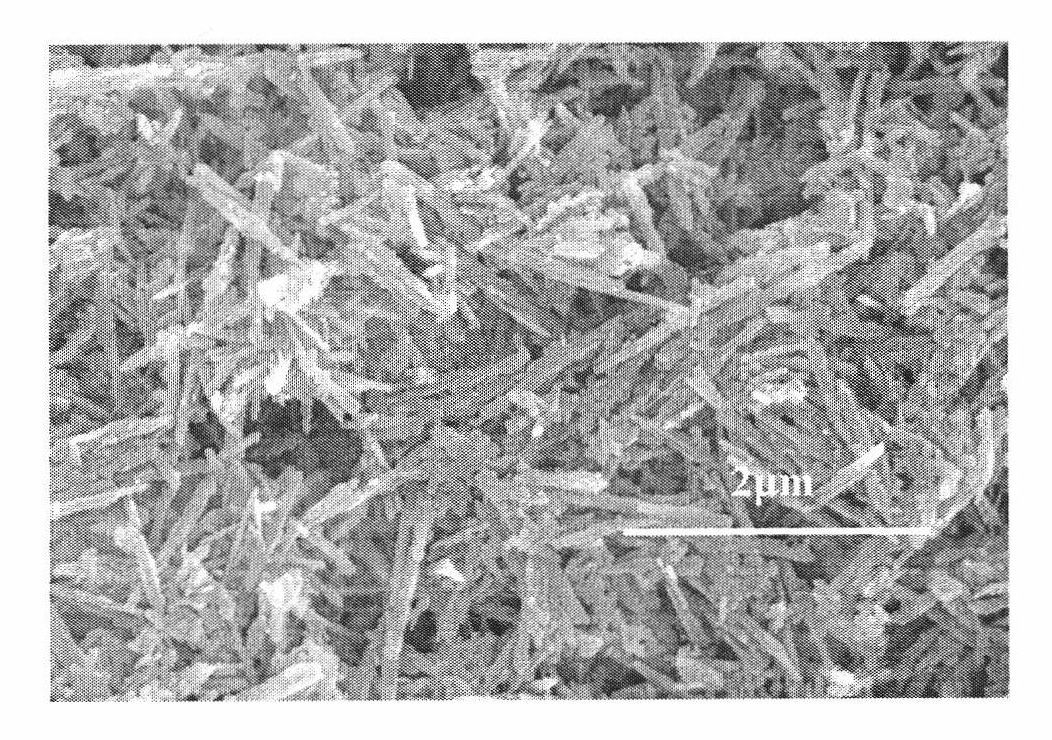

[0028] attached figure 1 And attached figure 2 XRD and SEM images of the precursor. Both indicate that the precursor is BaCO 3 The composite formed on the surface of ...

Embodiment 2

[0031] Prepare BaFe by the step of embodiment 1 12 o 19 , the different reaction conditions are: Fe / Ba=12 (molar ratio), the reaction temperature is 30°C, α-FeOOH is used to replace γ-FeOOH, and Na 2 CO 3 The solution time was controlled to be 12 hours, the standing time was 18 hours, and the precursor was calcined at 1100° C. for 1.5 hours.

[0032] attached Figure 5 is the SEM figure of the final product, it shows that the final product BaFe 12 o 19 The one-dimensional rod-shaped morphology features are not obvious, indicating that high temperature affects the shape retention, the aspect ratio is 3-5, and the particle length is 0.3-0.7μm. VSM analysis shows that its coercive force is 2365Oe and its saturation magnetization is 49.99emu / g.

[0033] Compared with Example 1, this example shows that by adjusting the reaction conditions, BaCo x Ti x Fe 12-2x o 19 (x=O-1) particle length-to-diameter ratio and size can be adjusted to adjust its static magnetic properties....

Embodiment 3

[0035] Take x=0.5, according to Fe:Ba:Co:Ti=10.6:1:0.5:0.5, weigh BaCl 2 、CoCl 2 , γ-FeOOH and tetrabutyl titanate. The specific steps are the same as in Example 1, the difference is: take tetrabutyl titanate and dissolve it in ethanol, and dissolve Na 2 CO 3 The solution and tetrabutyl titanate ethanol solution were added dropwise into the reactor at the same time, the precursor was pre-calcined at 350°C for 3 hours, and then calcined at 900°C for 1.5 hours.

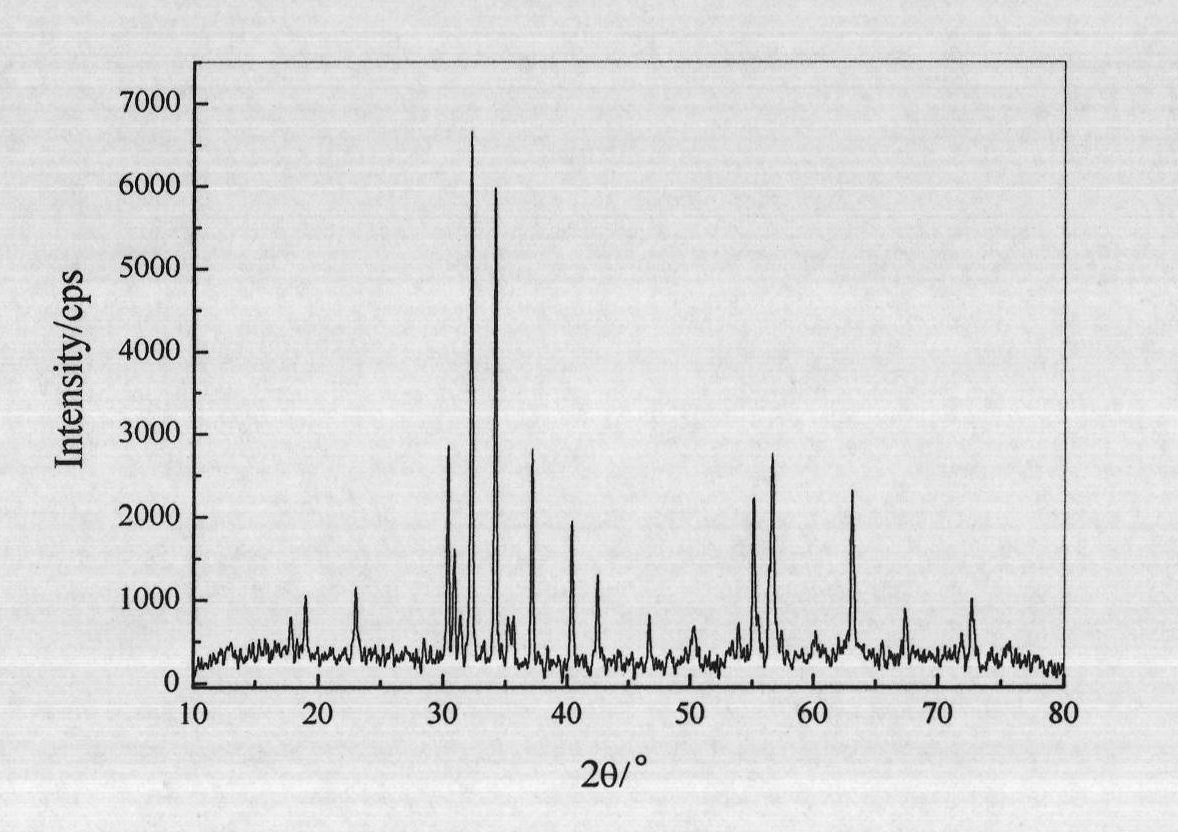

[0036] attached Image 6 , attached Figure 7 , attached Figure 8 They are the EDS diagram, XRD diagram and SEM diagram of the final product, respectively. attached by Image 6 It can be seen that the product contains Ba, Co, Ti, O, Fe elements and Ba: Co: Ti: Fe=1: 0.5: 0.5: 10.8 (molar ratio), combined with the attached Figure 7 It can be seen that the obtained product is barium ferrite and its chemical formula is BaCo 0.5 Ti 0.5 Fe 11 o 19 . attached Figure 8 Show BaCo 0.5 Ti 0.5 Fe 11 o 19 It ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com