Method for preparing 3,3-dimethyl butyraldehyde

A technology of dimethyl butyraldehyde and dimethyl butyryl chloride, which is applied in 3 fields, can solve the problems of serious environmental pollution, low yield, and large amount of hydrogen, and achieve high purity, high product yield, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

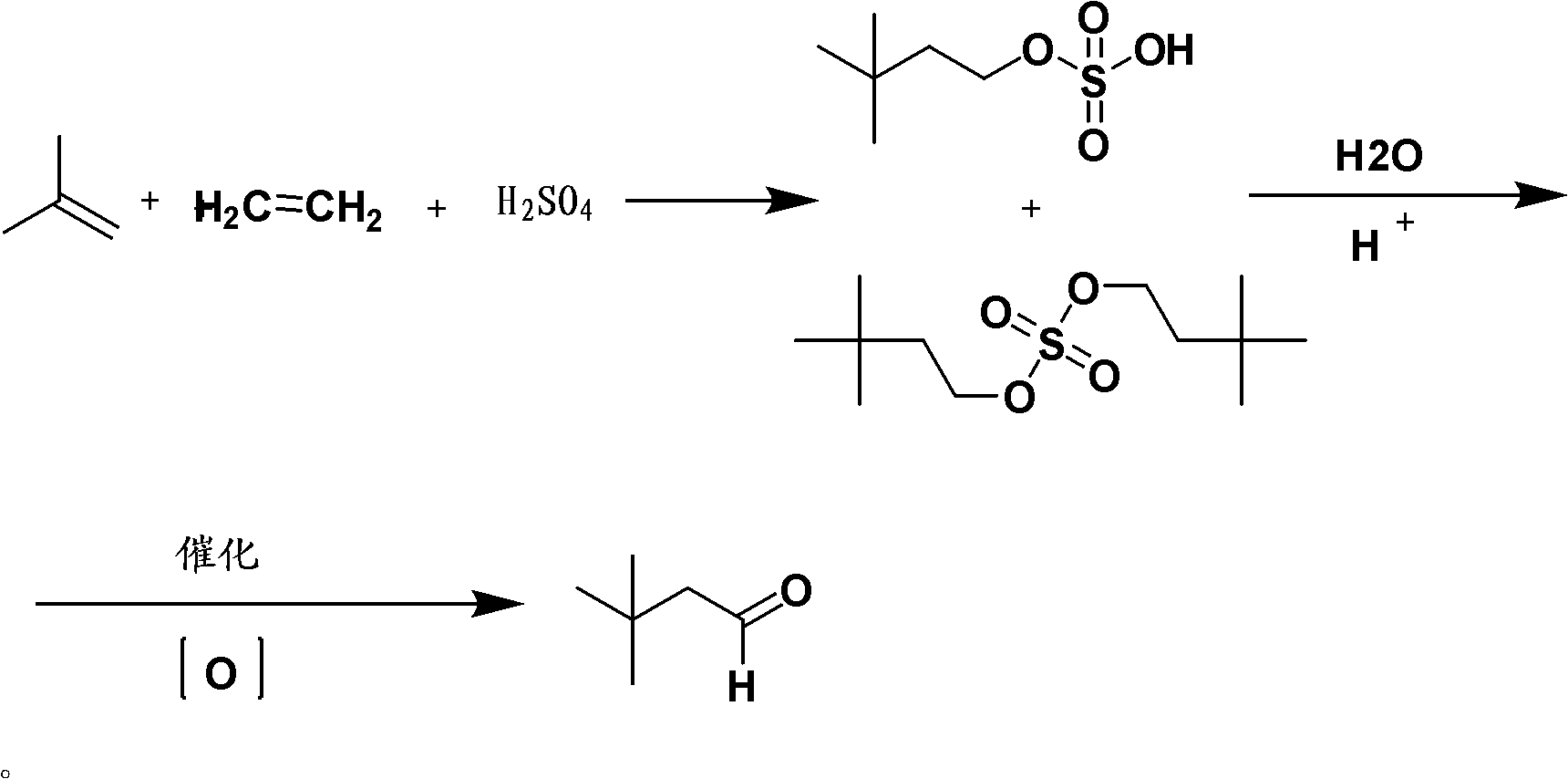

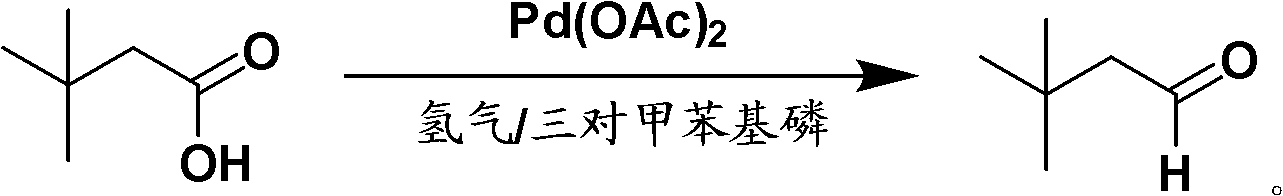

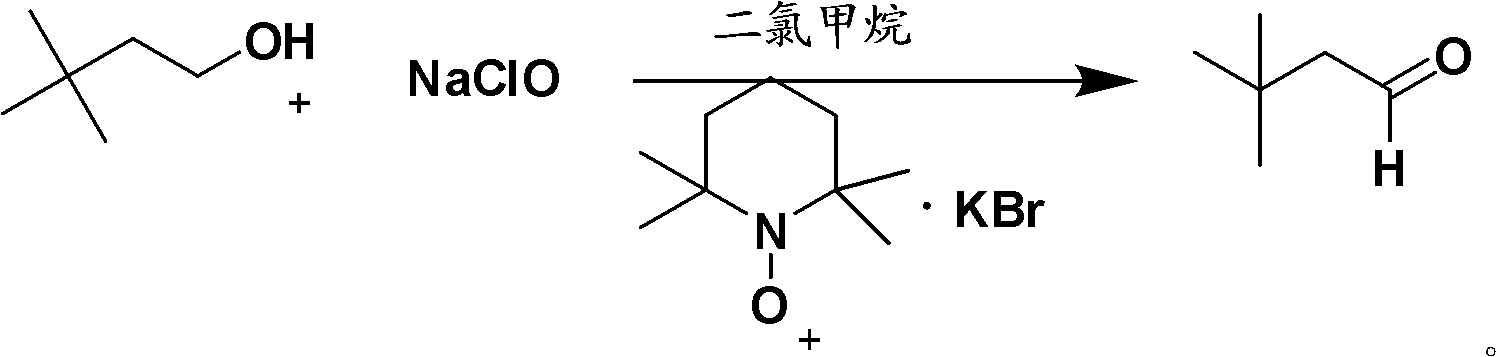

Method used

Image

Examples

Embodiment 1

[0030] Take a 10L high-pressure hydrogenation reactor and replace it with high-purity nitrogen three times, add 1L 3,3-dimethylbutyryl chloride, 3L anhydrous toluene, 20g 10% Pd / C, 1.2kg potassium carbonate, 40g CeCl 3 , Tighten the reaction kettle, replace it with high-purity nitrogen three times and high-purity hydrogen three times in sequence, control the pressure inside the kettle to 40psi, stir at 1000 rpm, slowly raise the temperature to 130°C, react for about 2 hours, and no longer absorb hydrogen to indicate the reaction complete. After cooling down to room temperature, replace it with nitrogen three times, filter and recover Pd / C, collect the 100-105°C fraction of the filtrate with a rectification column, and obtain 680g of the product, with a yield of 94% and a GC of 98.7%.

Embodiment 2

[0032] Take a 10L high-pressure hydrogenation reactor and replace it with high-purity nitrogen three times, add 1.5L 3,3-dimethylbutyryl chloride, 3L anhydrous dioxane, 40g 10% Pt / C, 950g anhydrous pyridine, 60g CuCl, twist The reaction kettle was replaced three times with high-purity nitrogen and three times with high-purity hydrogen in sequence. The pressure inside the kettle was controlled at 25 psi, the stirring speed was 1000 rpm, and the temperature was slowly raised to 120 ° C. The reaction was about 1.5 hours. If no more hydrogen was absorbed, the reaction was complete. After cooling down to room temperature, replace with nitrogen three times, filter and recover Pt / C, wash the filtrate with 10L of 5% salt water to remove the solvent, and rectify the obtained oily product with a rectification column, collect fractions at 100-105°C, and obtain 970g of the product with a yield of 90%, GC99 .2%.

Embodiment 3

[0034] Take a 10L high-pressure hydrogenation reactor and replace it with high-purity nitrogen three times, add 1.5L 3,3-dimethylbutyryl chloride, 4L ethylene glycol dimethyl ether, 60g 5% Pd / C, 1kg lithium carbonate, 50g MgCl 2 , Tighten the reactor, replace it with high-purity nitrogen three times and high-purity hydrogen three times in turn, control the pressure inside the kettle to 60 psi, stir at 1000 rpm, slowly raise the temperature to 100°C, react for about 4 hours, and no longer absorb hydrogen to indicate the reaction complete. After cooling down to room temperature, replace with nitrogen three times, filter to recover Pd / C, wash the filtrate with 15L of 5% brine, and collect the 100-105°C fraction of the oily product with a rectification column to obtain 950g of the product, with a yield of 88% and a GC of 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com