Low-temperature quick-drying solvent-free epoxy coating for drinking water tank and preparation method thereof

An epoxy coating, solvent-free technology, applied in the field of coating manufacturing, can solve the problems of slow reaction speed, long hardening time, difficult to adapt to the requirements of coating process, etc., and achieve the effect of fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

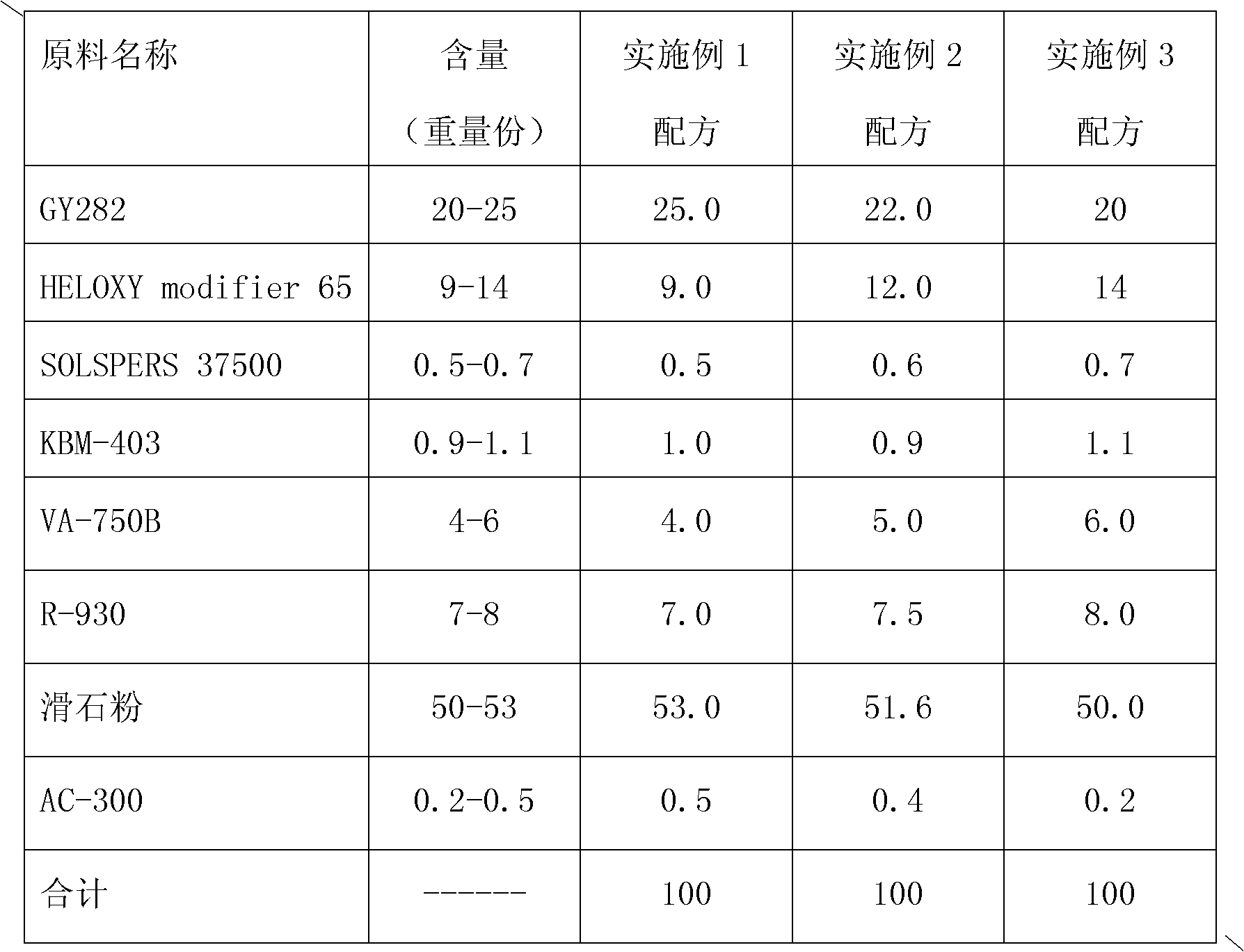

[0045] 1) Preparation of epoxy components: drop into 25 parts by weight of small molecule bisphenol F epoxy resin (GY282), 9 parts by weight of reactive diluent (HELOXY modifier 65), 0.5 parts by weight of dispersant ( SOLSPERS37500), 1.0 parts by weight of silane coupling agent (KBM-403), 0.5 parts by weight of defoamer (AC-300), start to stir evenly, and add the following components respectively under the condition of stirring: 4 parts by weight of thixotropic agent ( VA-750B), 7 parts by weight of titanium dioxide (R-930), 53 parts by weight of low oil absorption talcum powder, disperse at high speed for 30 minutes, then grind to standard fineness with a sand mill or three-roll mill, filter and pack to become a coating A component.

[0046] 2) Put 95 parts by weight of commercially available modified aromatic amine curing agent Aradur 847 and 5 parts by weight of K-54 into the dispersing tank and stir evenly, then pack them into small barrels according to the matching and p...

Embodiment 2

[0056]3) Preparation of epoxy components: drop into 22 parts by weight of small molecule bisphenol F epoxy resin (GY282), 11 parts by weight of reactive diluent (HELOXY modifier 65), 0.6 parts by weight of dispersant ( SOLSPERS37500), 0.9 parts by weight of silane coupling agent (KBM-403), 0.4 parts by weight of defoamer (AC-300), start to stir evenly, and add the following components respectively under the condition of stirring: 5 parts by weight of thixotropic agent ( VA-750B), 7.5 parts by weight of titanium dioxide (R-930), 51.6 parts by weight of low oil absorption talcum powder, disperse at high speed for 30 minutes, then grind to standard fineness with a sand mill or a three-roll mill, filter and pack to become a coating A component.

[0057] 4) Put 95 parts by weight of commercially available modified aromatic amine curing agent Aradur 847 and 5 parts by weight of K-54 into the dispersing tank and stir evenly, then pack them into small barrels according to the matching...

Embodiment 3

[0060] 5) Preparation of epoxy components: drop into 20 parts by weight of small molecule bisphenol F epoxy resin (GY282), 14 parts by weight of reactive diluent (HELOXY modifier 65), 0.7 parts by weight of dispersant ( SOLSPERS37500), 1.1 parts by weight of silane coupling agent (KBM-403), 0.2 parts by weight of defoamer (AC-300), start to stir evenly, and add the following components respectively under the condition of stirring: 6 parts by weight of thixotropic agent ( VA-750B), 8 parts by weight of titanium dioxide (R-930), 50 parts by weight of low oil absorption talcum powder, disperse at high speed for 30 minutes, then grind to standard fineness with a sand mill or three-roller mill, filter and pack to become a coating A component.

[0061] 6) Put 95 parts by weight of commercially available modified aromatic amine curing agent Aradur 847 and 5 parts by weight of K-54 into the dispersing tank and stir evenly, then pack them into small barrels according to the matching an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com