Hemp degumming method

A degumming method and hemp technology, applied in the field of degumming technology, can solve the problems of low strength of hemp fibers, long degumming period, low hemp yield, etc., and achieve the effects of improving the strength of hemp fibers, saving the heating process, and improving the hemp yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

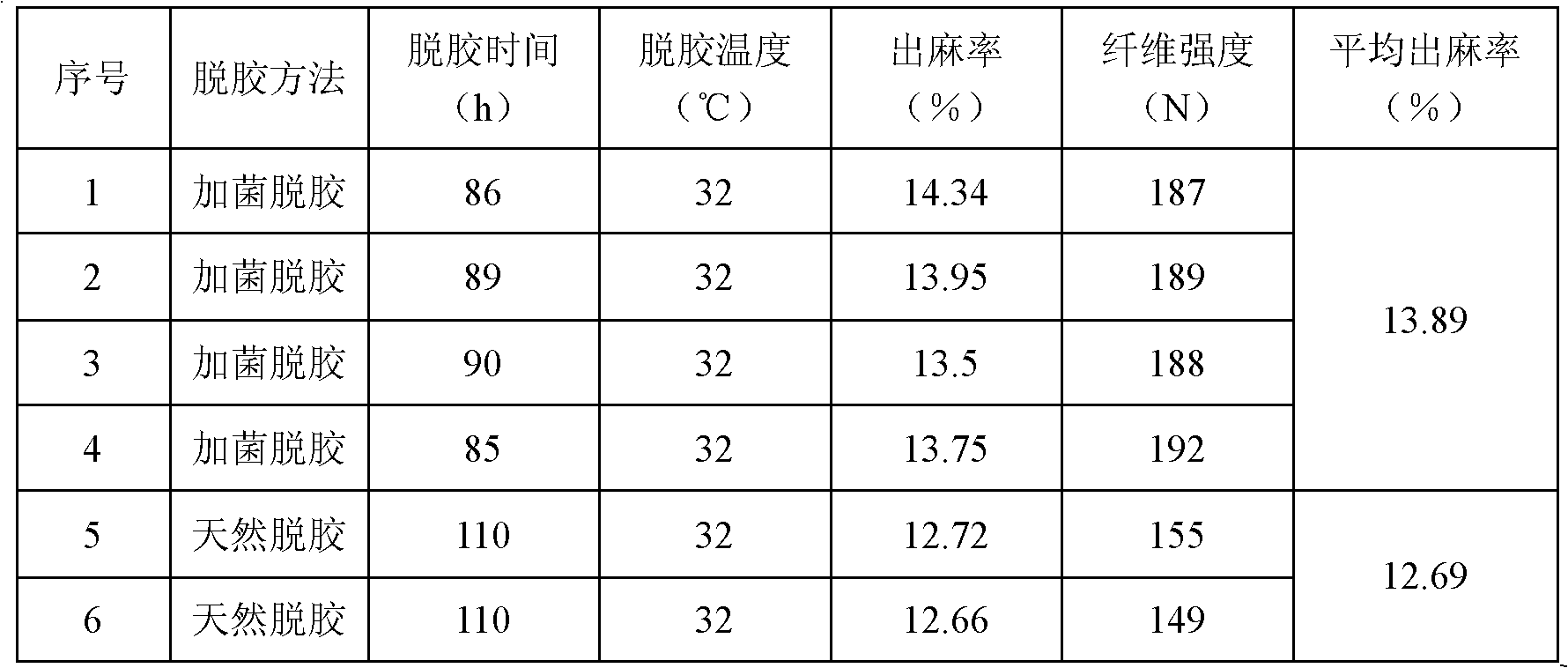

Examples

specific Embodiment approach 1

[0011] Specific embodiment 1: A cannabis degumming method according to the present embodiment can be realized according to the following steps: 1. Activation of strains for cannabis degumming: Escherichia coli HDDMG05 and Bacillus licheniformis HDDMM02 are treated in beef extract peptone at 30°C, respectively. Cultivate on the medium for 24 hours; 2. Primary seed culture: use an inoculation loop to pick the activated strains in step 1 and insert them into 200-500 mL of industrial expansion medium, and cultivate at 28-32 °C for 20-30 hours; 3. 、Secondary seed culture: insert the bacterial liquid after the first seed culture into 200~500L industrial expansion medium according to the volume fraction of 0.5%~2%, and cultivate at 28~32℃ for 20~30h ;Fourth and three-level seed culture: insert the bacterial liquid after the second-level seed culture into the 2-5t industrial expansion medium according to the volume fraction of 0.5%-2%, and cultivate it under the condition of 28-32 ℃ fo...

specific Embodiment approach 2

[0013] Specific embodiment 2: The difference between this embodiment and the specific embodiment 1 is that in step 2, the strains activated in step 1 are respectively picked with an inoculation loop and inserted into 250-400 mL of industrial expansion medium, and cultured at 30°C for 24 hours. . Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 3, the bacterial liquid after the first-level seed cultivation is connected to 250-400L industrial expansion according to the volume fraction of 1%-1.5% of the inoculum. cultured at 30°C for 24h. Other steps and parameters are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com