Single-layer capacitor and preparation method thereof

A capacitor, single-layer technology, applied in the direction of capacitors, fixed capacitors, fixed capacitor electrodes, etc., can solve the problems of unfavorable miniaturization of single-layer ceramic capacitors, difficulty in achieving ultra-thin thickness of electrode layers, and thin thickness of single-layer ceramic capacitors, etc. Achieve the effect of ultra-thin thickness, improved finished product qualification rate, and guaranteed flatness and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

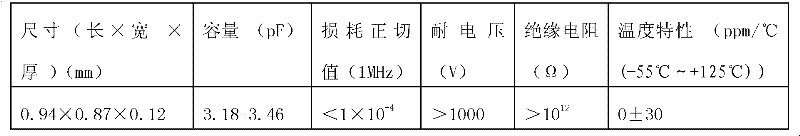

[0029]Add ceramic powder, plasticizer, dispersant, defoaming agent, toluene and ethanol in the ball milling jar according to the formula ratio, ball mill at 60-85 rpm for 4 hours, and then add adhesive into the jar for 8 hours to make Porcelain slurry. Cast the prepared porcelain slurry into a 30um dielectric film with a steel belt casting machine. The diaphragms are stacked according to the total thickness of the design, and the oil pressure is 10Mpa / 60℃ / 2min to obtain the bar. The bar block was bagged and vacuumed, and after lamination at 40Mpa / 68°C / 10min, the laminated ceramic medium bar was cut into square ceramic green sheets of 50mm×50mm with a straight knife cutting machine. According to the above method, the square ceramic green sheets are sintered in an air tunnel furnace after being placed in a pot, and the sintering curve is shown in Table 1.

[0030] Table 1: Sintering curves

[0031] Sintering curve stage

Heat-up and degumming section

Rapid hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com