Method for preparing photo-electrode

A technology of photoelectrodes and conductive substrates, applied in the field of solar photoelectric conversion, can solve the problems of unfavorable practical application of industrial production, complex operation of chemical deposition method, low photoelectric energy conversion efficiency, etc., to achieve improved photoelectric conversion efficiency, simple equipment and low production cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

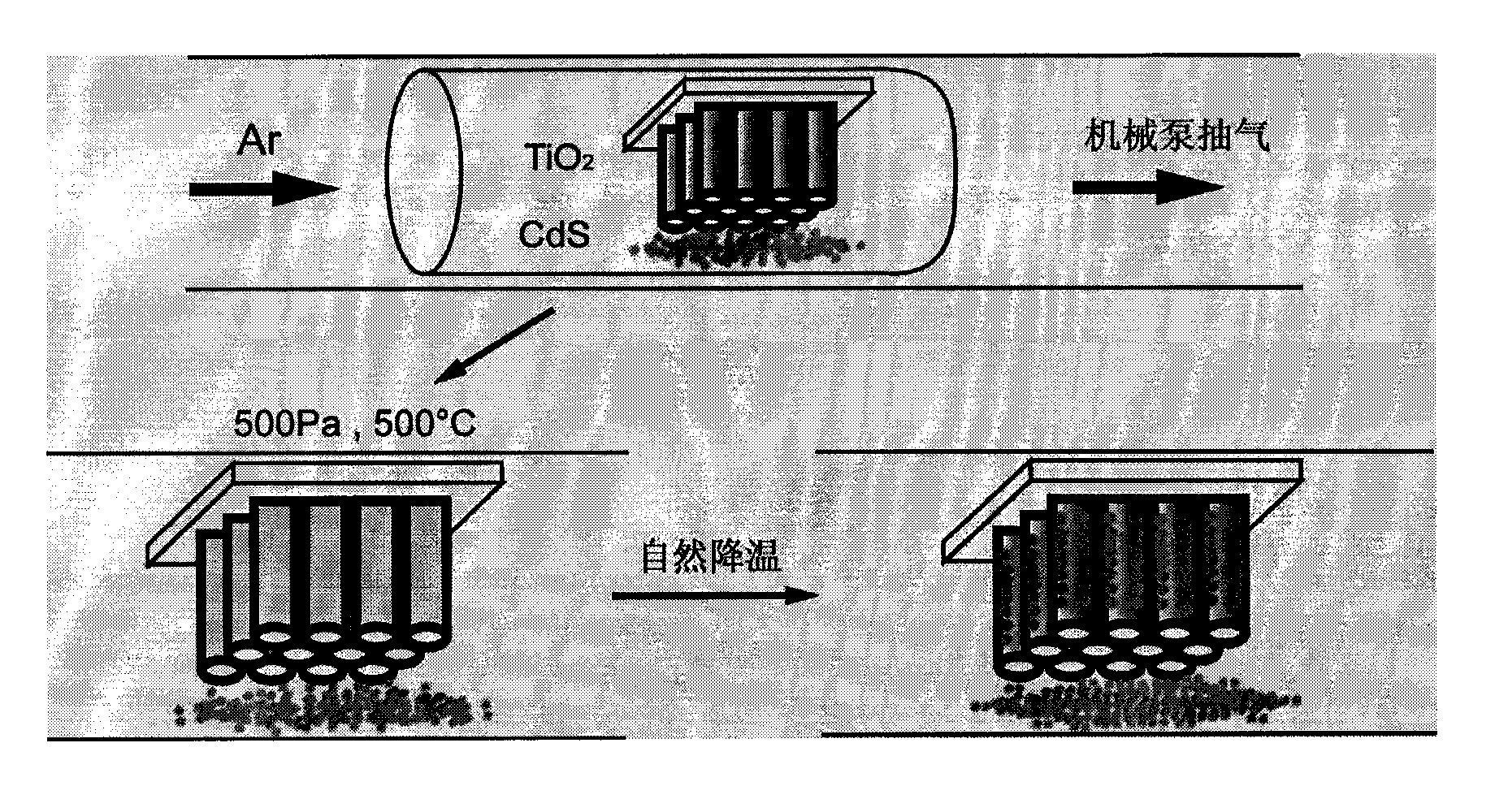

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail through the embodiment, but the present invention is not limited in any way.

[0021] Taking the preparation of cadmium sulfide / titanium dioxide heterojunction photoelectrode as an example, the following steps are included:

[0022] (1) Utilize the method for anodic oxidation to obtain titanium dioxide nanotube array on a conductive substrate;

[0023] (2) in the quartz tube of the tube furnace, the titanium dioxide nanotube array opening prepared in step (1) is suspended above the cadmium sulfide powder downward;

[0024] (3) Feed argon to clean the quartz tube twice, and adjust the air pressure of the system between 500Pa-600Pa under an argon atmosphere;

[0025] (4) Heat the system to 500°C. As the temperature increases, cadmium sulfide becomes gaseous and infiltrates into the titanium dioxide nanotube array, and reaches a saturated state;

[0026] (5) After 15-25 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com