Susceptor structure and processing apparatus

A technology for mounting tables and processing containers, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc. It can solve problems such as high operating costs, leakage, and consumption of purge gas, and achieves prevention of damage, suppression of supply, and suppression of being damaged. The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

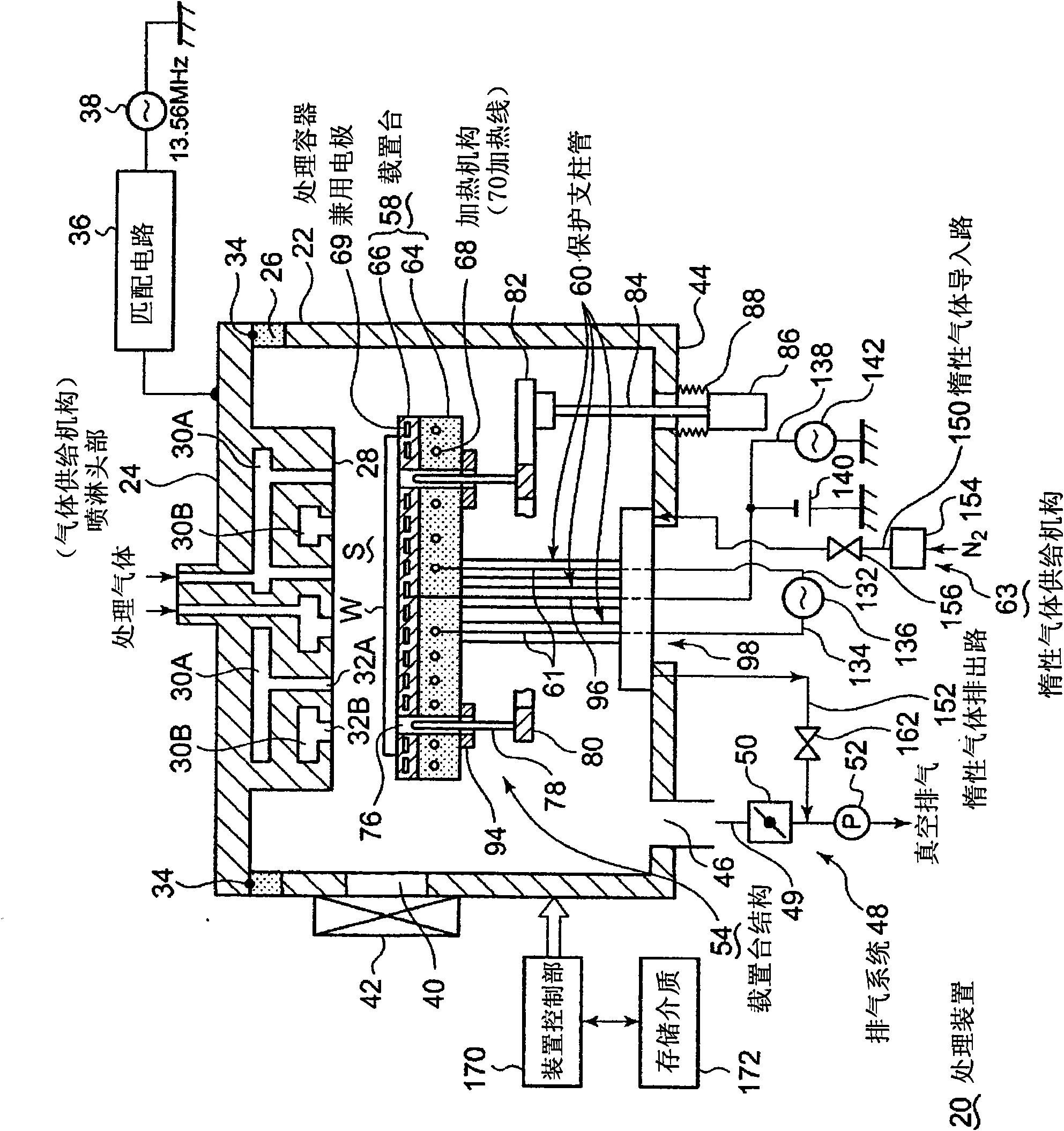

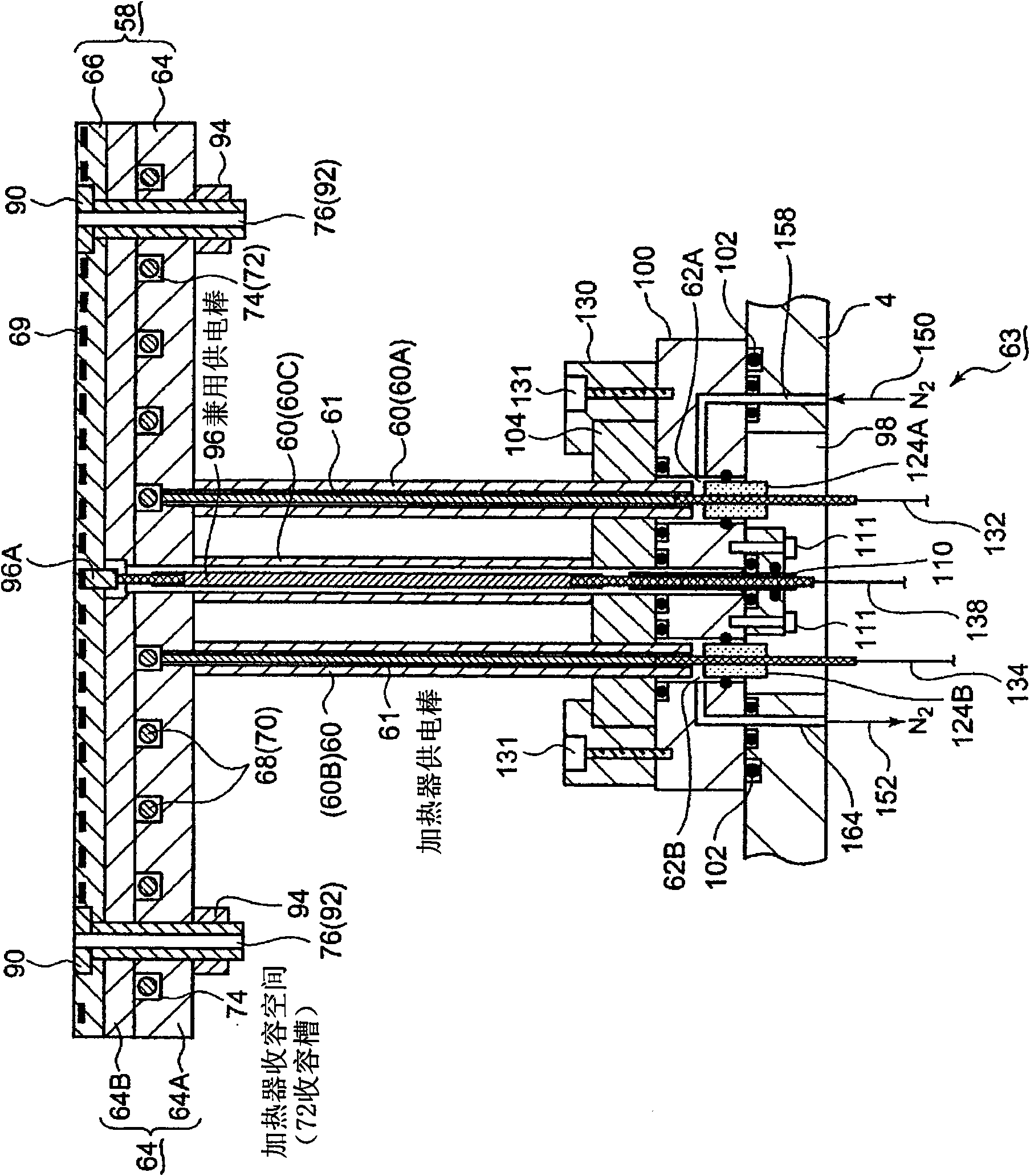

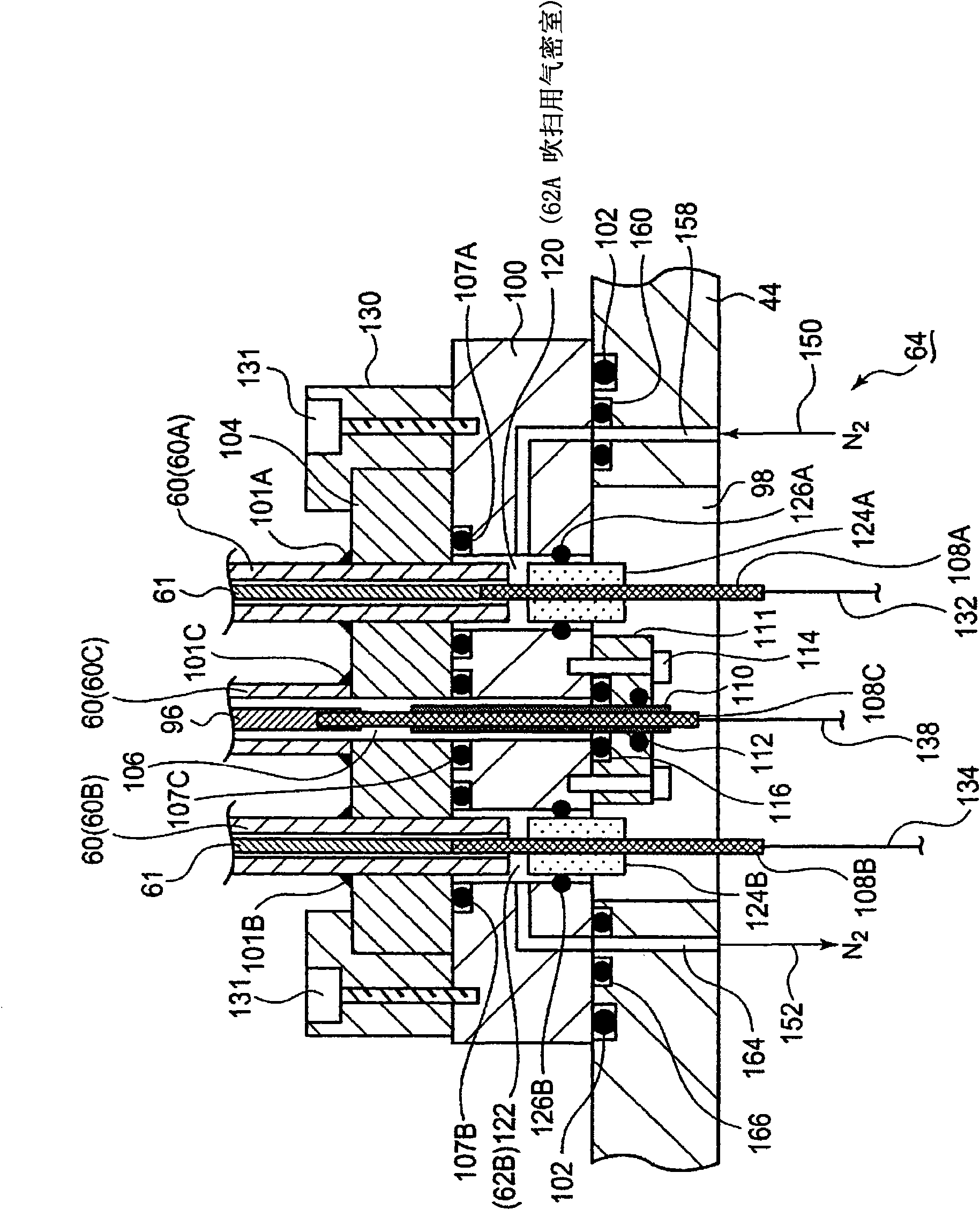

[0059] Hereinafter, a suitable embodiment of the mounting table structure and the processing apparatus of the present invention will be described based on the drawings. figure 1 It is a cross-sectional structural view showing a processing device having a mounting table structure of the present invention, figure 2 is an enlarged cross-sectional view of the mounting table structure, image 3 is an enlarged cross-sectional view showing the mounting portion of the mounting table structure, Figure 4 is a schematic diagram showing a horizontal cross-section of the lower part of the mounting table structure, Figure 5 It is a schematic plan view showing the arrangement state of the heater wires of the heating mechanism of the stage. Here, a film formation process using plasma will be described as an example.

[0060] As shown in the drawing, this processing apparatus 20 has, for example, a processing container 22 made of aluminum (including aluminum alloy) whose cross section i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com