Method of drying and/or curing an organic coating on a continuously running metal strip, and device for implementing this method

A metal belt, moving direction technology, applied in the direction of dryers, progressive dryers, devices for coating liquid on the surface, etc., can solve problems such as burning, achieve high drying temperature, and ensure the effect of drying temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

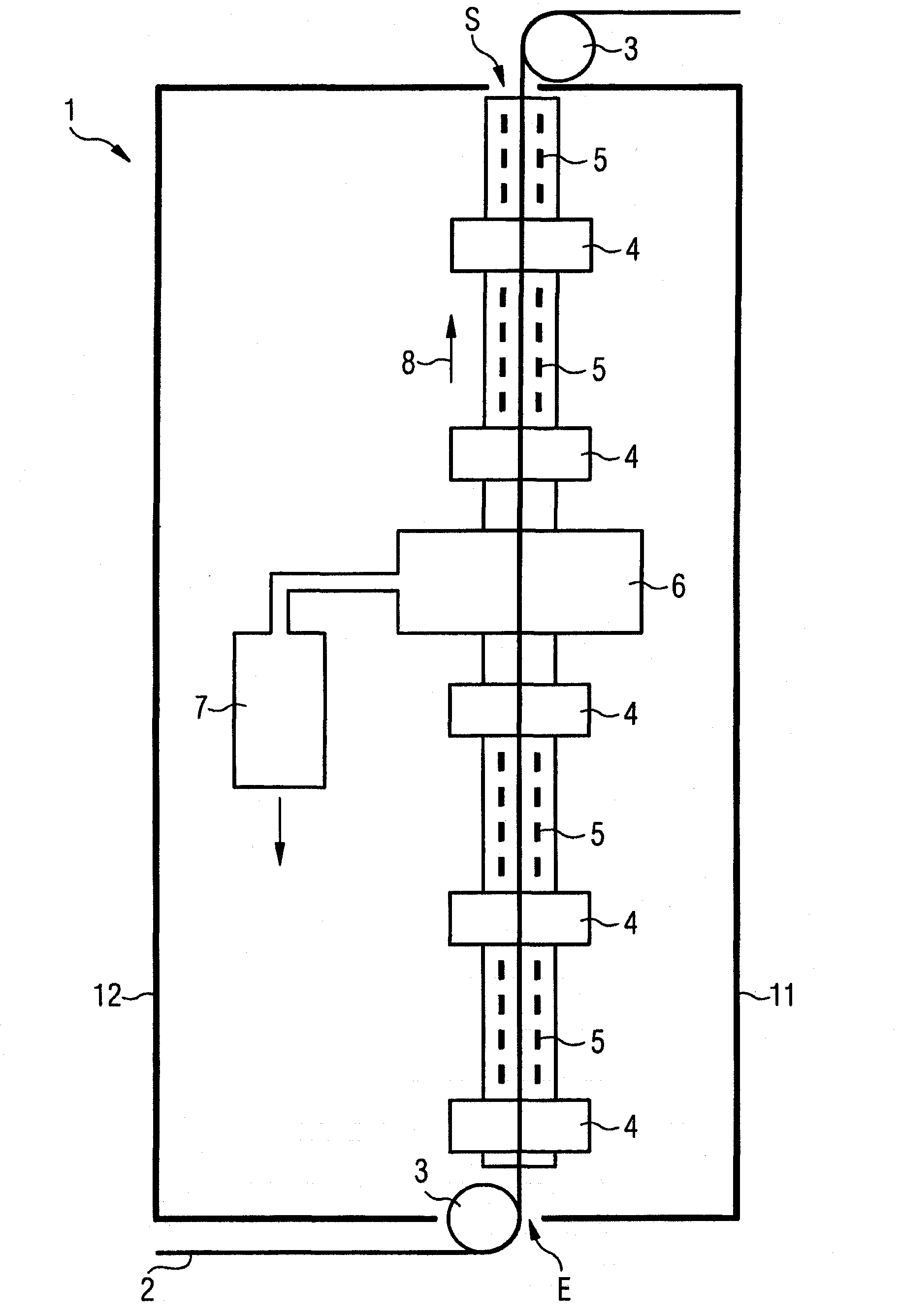

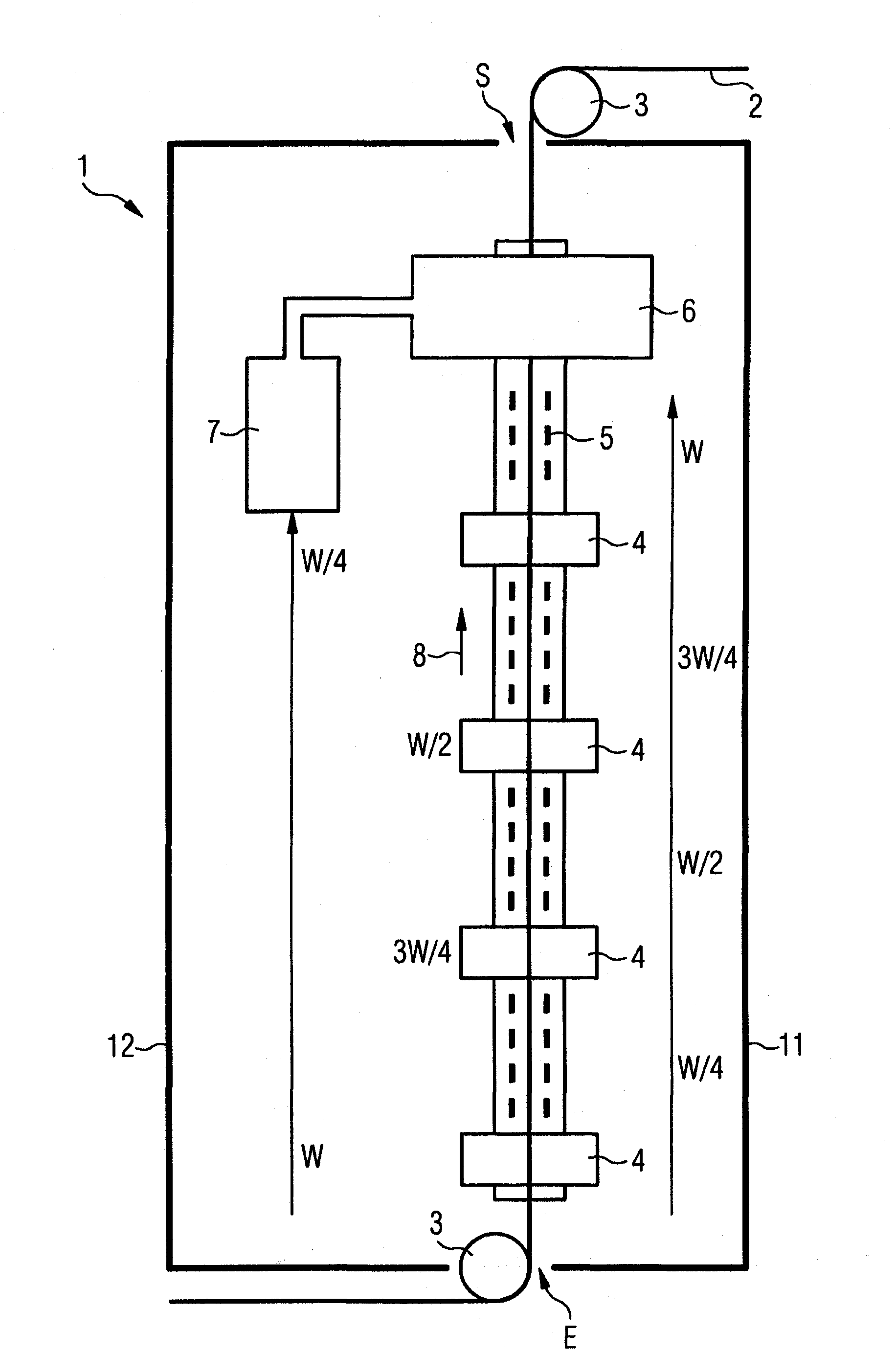

[0047] exist figure 1 Drying and / or drying units shown in include:

[0048] - a furnace 1, preferably vertical and forming a tunnel, through which the steel strip 2, which has previously been deposited with an organic coating of the varnish or paint type; and

[0049] - means 3 (for example: deflecting rollers) for moving the strip 2 from the inlet E at the first end of the shell 11 of the furnace 1 to the outlet S at the other end of said shell 11 ,

[0050] Furnace 1 includes a hot inner wall (in figure 1 and 2 Not shown in the shell 11, which is equipped with:

[0051] - a plurality of inductors 4 distributed along the housing 11; and

[0052] • A plurality of infrared emitters 5 with catalytic burners (or sources of catalytic radiation) arranged alternately with the inductors 3 on both sides of the strip 2 .

[0053] Said plant 1 also comprises a recovery chamber 6 for oxidized gases and residual solvents, wherein said oxidized gases and residual solvents are directed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com