Method of reducing protein content in cut tobacco by enzymatic treatment

A protein and enzymatic degradation technology, used in the preparation of tobacco flavors and the field of tobacco flavors, can solve problems such as long time for enzyme treatment, and achieve the effects of improving quality, reducing content and increasing amino acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

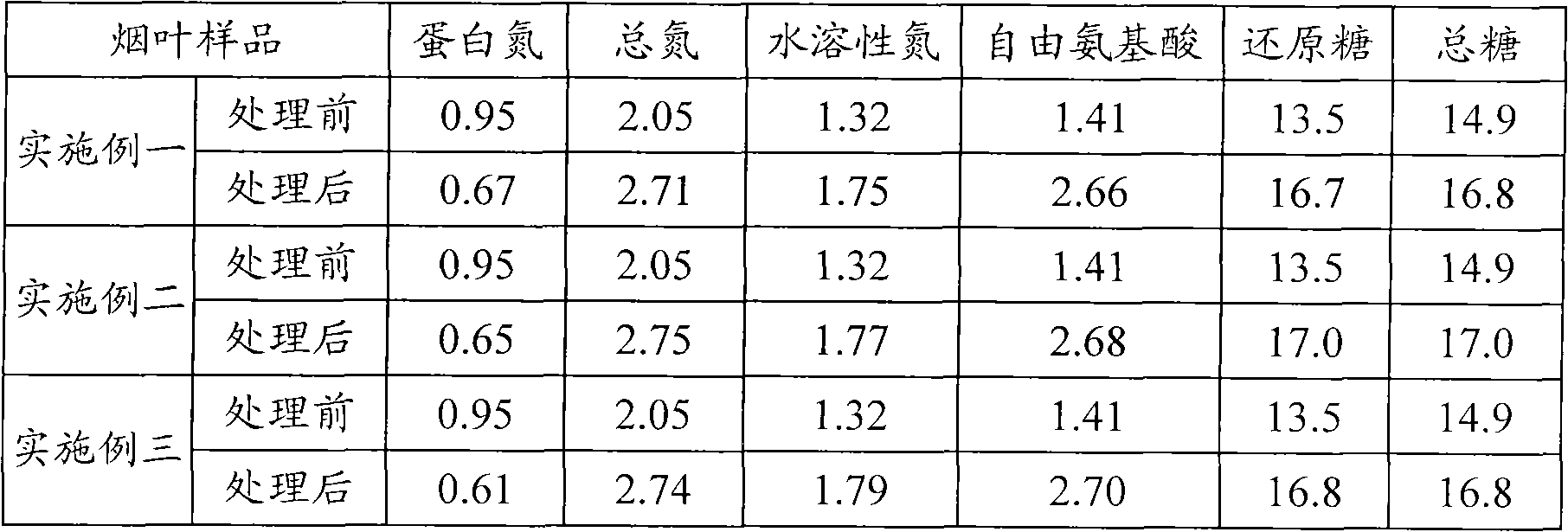

Examples

Embodiment 1

[0031] A method for enzymatically treating shredded tobacco to reduce protein content. The steps of this method are as follows:

[0032] (1) Tobacco leaf pretreatment: Accurately weigh 250 grams of tobacco leaves (CX2K variety) and rinse with water, heat and sterilize at 100°C for 30 minutes, filter and dry after cooling, and dry to a humidity of 10%, the system temperature is kept at 40°C .

[0033] (2) Preparation of enzyme solution: the protease used in this step is papain produced by Nanning Pangbo Bioengineering Co., Ltd., with an activity of 50000U / g.

[0034] (3) Enzymolysis: the enzyme solution prepared in step (2) is sprayed onto the surface of the tobacco leaves pretreated in step (1), and the amount of enzyme solution added is 2% in terms of the total weight of the tobacco leaves , with a humidity of 50%, then mixed evenly, sealed with a sealed bag, and placed in a constant temperature incubator at 40°C for 24 hours for enzymolysis.

[0035] (4) Subsequent treatm...

Embodiment 2

[0038] A method for enzymatically treating shredded tobacco to reduce protein content. The steps of this method are as follows:

[0039] (1) Tobacco leaf pretreatment: Accurately weigh 250 grams of tobacco leaves (CX2K variety), rinse with water, heat and sterilize at 115°C for 20 minutes, filter and dry after cooling, and dry to a humidity of 12%. The system temperature is maintained at 50°C .

[0040] (2) Preparation of enzyme solution: the protease used in this step is an acid protease produced by Nanning Pangbo Bioengineering Co., Ltd., with an activity of 80000U / g.

[0041] (3) Enzymolysis: the enzyme solution prepared in step (2) is sprayed onto the surface of the tobacco leaves pretreated in step (1), and the amount of enzyme solution added is 2% in terms of the total weight of the tobacco leaves , with a humidity of 50%, then mixed evenly, sealed with a sealed bag, and placed in a constant temperature incubator at 50°C for 12 hours for enzymolysis.

[0042] (4) Subs...

Embodiment 3

[0045] A method for enzymatically treating shredded tobacco to reduce protein content. The steps of this method are as follows:

[0046] (1) Tobacco leaf pretreatment: Accurately weigh 250 grams of tobacco leaves (CX2K variety) and rinse with water, heat and sterilize at 121°C for 15 minutes, filter and dry after cooling, and dry to a humidity of 15%, and keep the system temperature at 60°C .

[0047](2) Preparation of enzyme solution: the protease used in this step is bromelain produced by Nanning Pangbo Bioengineering Co., Ltd., with an activity of 100000U / g.

[0048] (3) Enzymolysis: the enzyme solution prepared in step (2) is sprayed onto the surface of the tobacco leaves pretreated in step (1), and the amount of enzyme solution added is 5% based on the total weight of the tobacco leaves , with a humidity of 50%, then mixed evenly, sealed with a sealed bag, and placed in a constant temperature incubator at 60°C for 6 hours for enzymolysis.

[0049] (4) Subsequent treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com