Water-based two-component acrylic acid polyurethane automobile paint and preparation method thereof

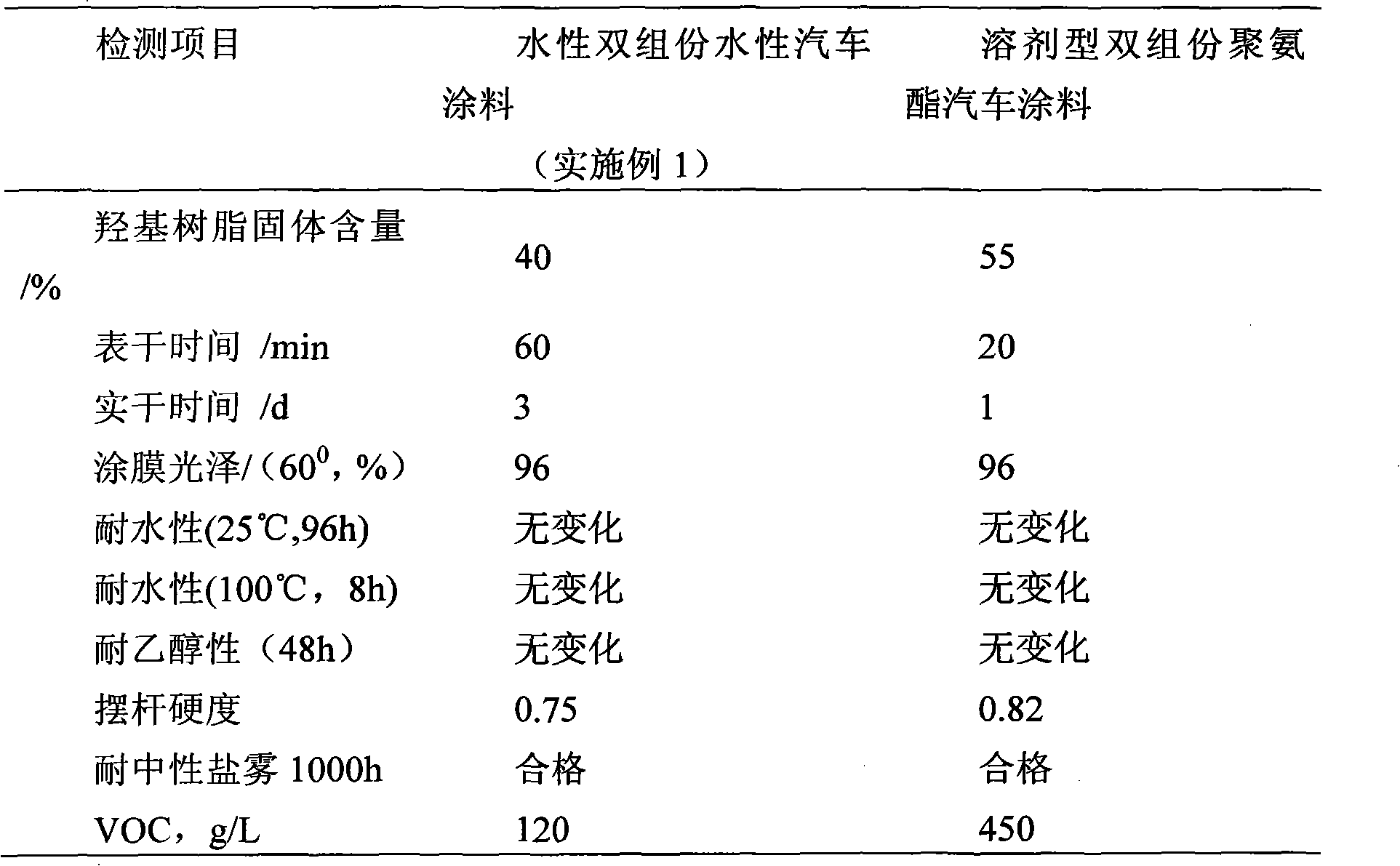

An acrylic polyurethane, water-based two-component technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of reducing the storage stability of water-based resins, increasing the complexity of construction, and poor storage stability. The effect of film appearance and gloss, improving gloss and appearance, improving water resistance and resistance to other chemical media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add water-based hydroxyacrylic resin, wetting agent, defoamer, thickener, coupling agent, and film-forming aid into deionized water according to the dosage of the formula, and disperse at 800RPM disperser for 15 minutes to make component A; Weigh the polyisocyanate curing agent as the B component according to the amount of the formula, and control the molar ratio of the OH group contained in the water-based hydroxyl resin in the A component to the NCO group contained in the polyisocyanate in the B component to be 1 / 2.5. Slowly add component B to component A and continue to disperse for 5 minutes. The formula of the present embodiment is composed as follows:

[0026] A component:

[0027] Polyacrylate aqueous dispersion Bayhydrol XP2651: 80%;

[0028] TEG-245: 1%;

[0029] TEGO-805: 1%;

[0030] SN-612: 1%;

[0031] Glycidylalkyltrialkoxysilane: 3%;

[0032] Dipropylene glycol methyl ether: 2%;

[0033] Propylene glycol butyl ether: 3%;

[0034] Deionized water: ...

Embodiment 2

[0046] Add water-based hydroxyacrylic resin, wetting agent, defoamer, thickener, coupling agent, and film-forming aid into deionized water according to the dosage of the formula, and disperse for 15 minutes at the speed of the disperser at 300RPM to make component A; Weigh the polyisocyanate curing agent as the B component according to the amount of the formula, and control the molar ratio of the OH group contained in the water-based hydroxyl resin in the A component to the NCO group contained in the polyisocyanate in the B component to be 1 / 0.8. Slowly add component B to component A and continue to disperse for 5 minutes. The formula of the present embodiment is composed as follows:

[0047] A component:

[0048] Waterborne hydroxyl acrylic emulsion (Bayhydrol XP2546): 95%;

[0049] BYK-346: 0.1%;

[0050] TEGO-800: 0.04%;

[0051] BYK-020: 0.06%;

[0052] RM-2020: 0.1%;

[0053] Z-6040: 0.1%;

[0054] Z-6030: 0.1%;

[0055] Dipropylene glycol methyl ether acetate: 2%...

Embodiment 3

[0064] Add water-based hydroxyacrylic resin, wetting agent, defoamer, thickener, coupling agent, and film-forming aid into deionized water according to the dosage of the formula, and disperse at 1000RPM disperser for 15 minutes to make component A; Weigh the polyisocyanate curing agent as the B component according to the amount of the formula, and control the molar ratio of the OH group contained in the water-based hydroxyl resin in the A component to the NCO group contained in the polyisocyanate in the B component to be 1 / 1.5. Slowly add component B to component A and continue to disperse for 5 minutes. The formula of the present embodiment is composed as follows:

[0065] A component:

[0066] Waterborne hydroxyacrylic dispersion (Bayhydrol XP2651): 45%;

[0067] Waterborne hydroxyl acrylic emulsion (Bayhydrol XP2546): 47%;

[0068] TEGO-500: 0.5%;

[0069] TEGO-825: 0.5%;

[0070] BYK-19: 0.1%;

[0071] SN-612: 0.1%;

[0072] RM-2020: 0.3%;

[0073] 3,4 Cyclohexylep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com