Method for preparing fatty acid methyl ester and glycerol from kitchen waste oil by utilizing acid-base two-step method

A technology of fatty acid methyl ester and waste oil, which is applied in the direction of fatty acid esterification, alcoholysis preparation, biofuel, etc., can solve the problems of low recovery rate of glycerin and unusable products, etc., and achieves simple preparation method, low energy consumption and high efficiency. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

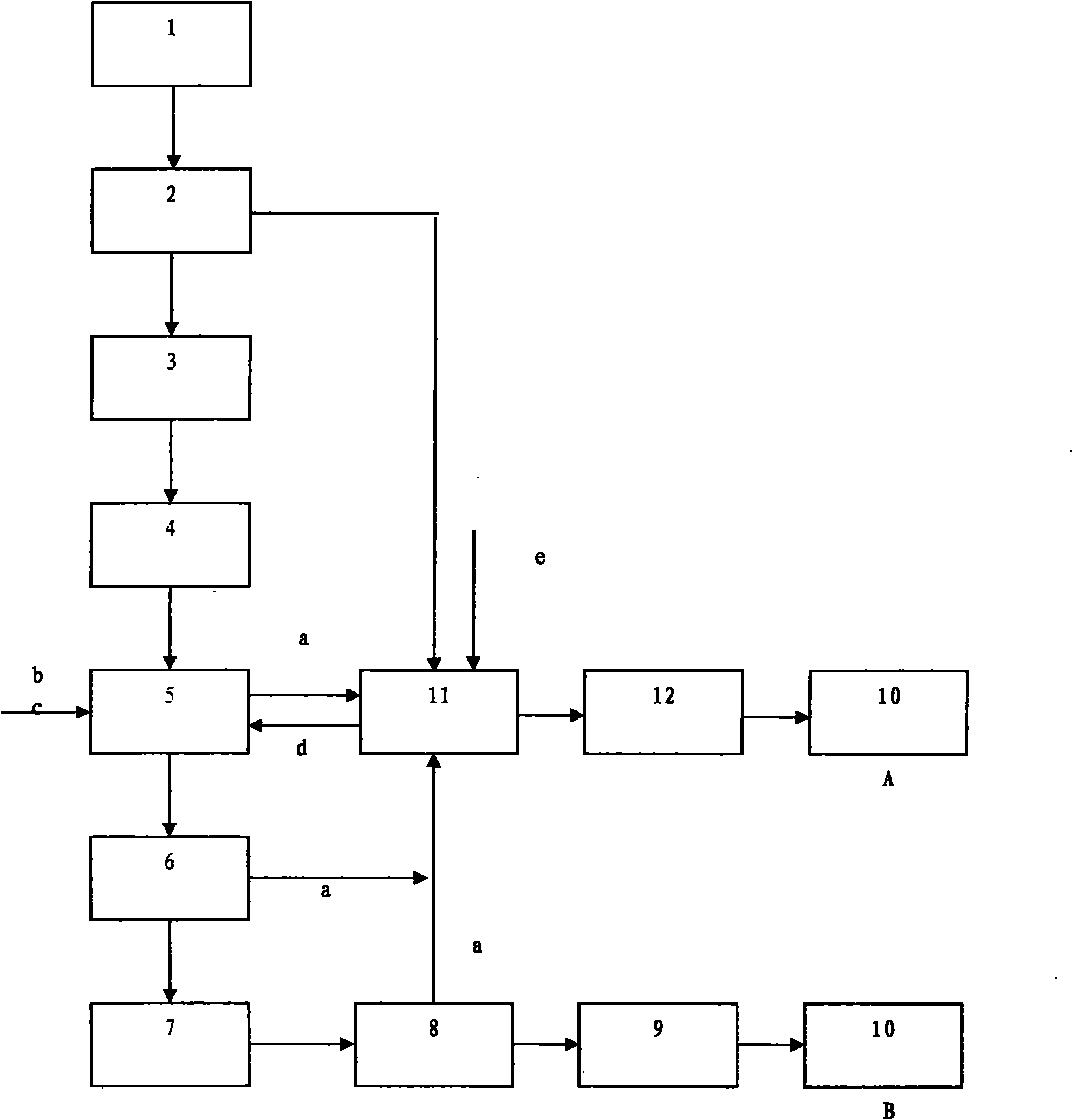

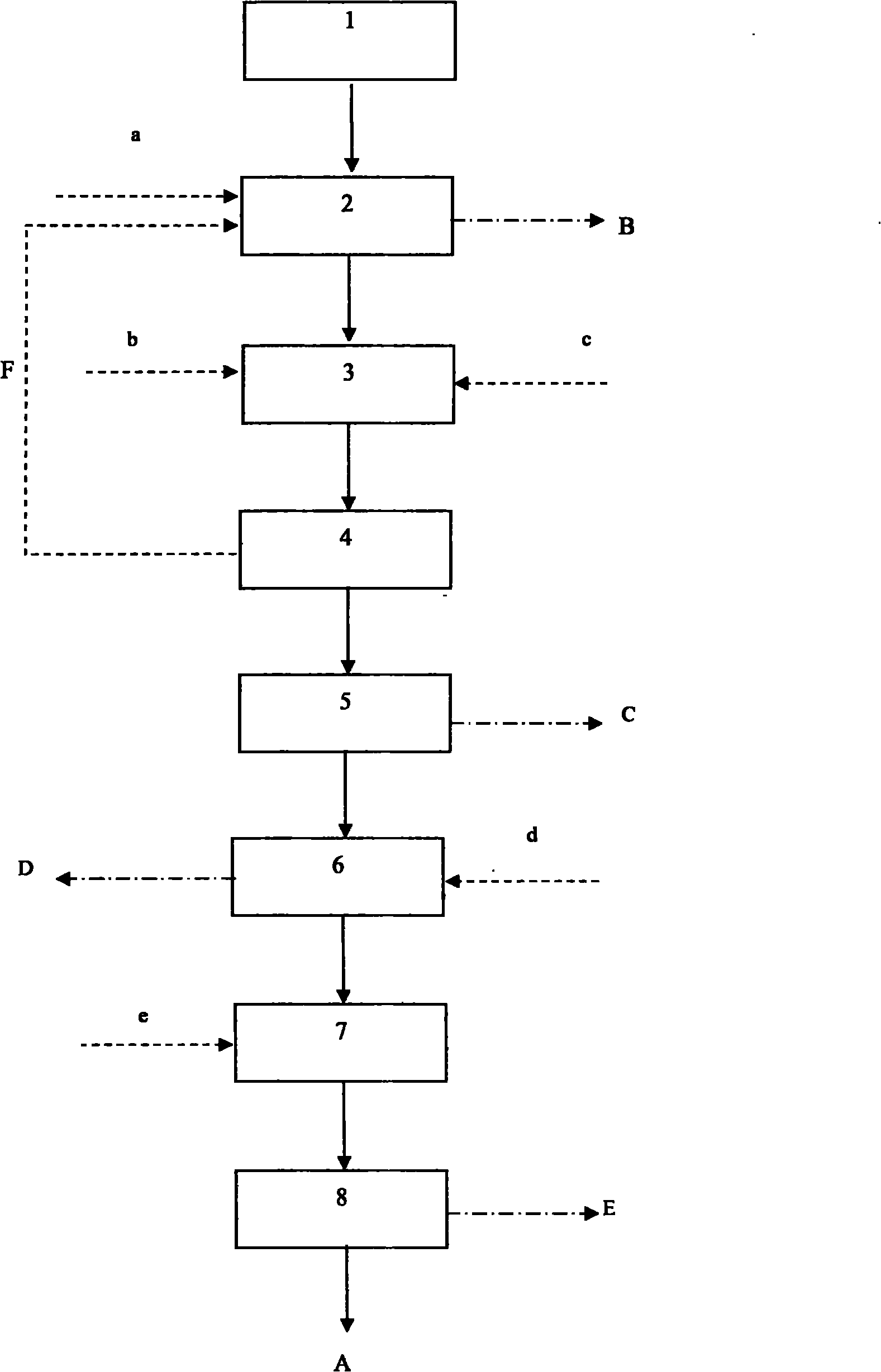

[0033] Take kitchen waste oil, after precipitation, filtration, water washing, dehydration, decolorization and other pretreatments, add anhydrous methanol and 40% sulfuric acid, the amount of methanol added is alcohol oil ratio 6:1 ~ 9:1, concentrated sulfuric acid is added The amount is acid-oil ratio (1-5):100. Heat to 60-65°C and stir at 200-400r / min for 3 hours. Leave to stand for stratification, the lower layer is a glycerin-water mixture, and the upper layer obtains an intermediate product-fatty acid methyl ester (biodiesel), oil, and a small amount of acid catalyst mixture; separate the mixture of fatty acid methyl ester and oil, and add a quantitative amount of alkali metal carbonate solution, wash and separate, and remove water at 105±5°C. Then, add anhydrous methanol and 5% sodium carbonate solution to the fatty acid methyl ester and oil mixture after washing according to the ratio of alcohol to oil 5:1, and heat at 50°C for 3 hours; Water mixture, the upper layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com