Hot-rolled H-shaped steel for low temperature-resisting structure and preparation method thereof

A technology for structural H-shaped steel, applied in the field of metallurgy, can solve the problems of increased cost and infeasibility, and achieve the effect of good low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Q345E

[0036] The process route is:

[0037] Hot metal pre-desulfurization→converter smelting→LF refining→shaped billet continuous casting→large H-beam rolling→inspection and storage.

[0038] The main technological measures of the preparation method:

[0039] (1) The molten iron goes to the desulfurization station for desulfurization of pure magnesium particles. After desulfurization, the sulfur content in the molten iron is guaranteed to be ≤0.020%.

[0040] (2) Converter smelting, after the converter smelting is completed, add synthetic slag in the ladle before tapping at a rate of 5kg / t steel, add 0.42kg / t ferroniobium during tapping, and add a modifier on the surface of the slag after tapping 1kg / t added. The composition of the synthetic slag, by weight percentage, is CaO: 48%, SiO 2 : 12%, Al 2 o 3 : 35%, MgO: 10%. The composition of the modifying agent is CaO: 30% by weight, SiO 2 : 10%, Al 2 o 3 : 30%, MgO: 15%, Al: 15%. Those skilled in t...

Embodiment 2

[0046] The composition of the synthetic slag described in step 1) is CaO: 55% by weight percentage, SiO 2 : 13%, Al 2 o 3 : 22%, MgO: 10%. The composition of the modifying agent is CaO: 40% by weight, SiO 2 : 8%, Al 2 o 3 : 35%, MgO: 6%, Al: 14%.

Embodiment 3

[0048] The composition of the synthetic slag described in step 1) is CaO: 50% by weight percentage, SiO 2 : 10%, Al 2 o 3 : 35%, MgO: 8%. The composition of the modifying agent is CaO: 50% by weight, SiO 2 : 5%, Al 2 o 3 : 20%, MgO: 7%, Al: 18%.

[0049] Table 1: Chemical Composition Weight % of Steel

[0050] Example

C

Si

mn

P

S

Nb

1

0.14

0.19

1.29

0.015

0.012

0.022

2

0.14

0.22

1.30

0.014

0.009

0.022

3

0.14

0.18

1.26

0.010

0.012

0.022

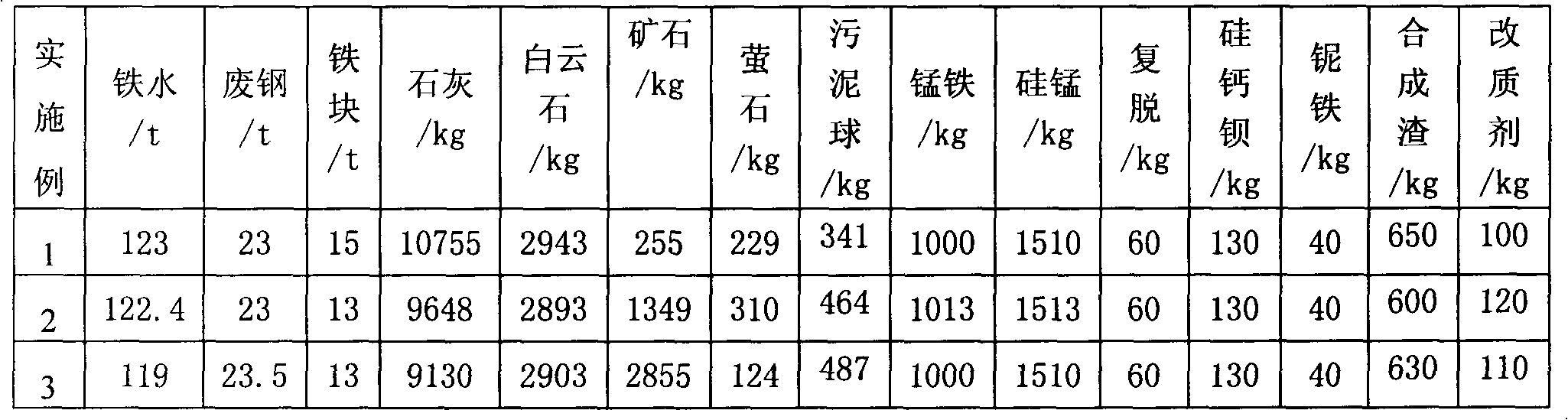

[0051] Table 2 Converter smelting process record table

[0052]

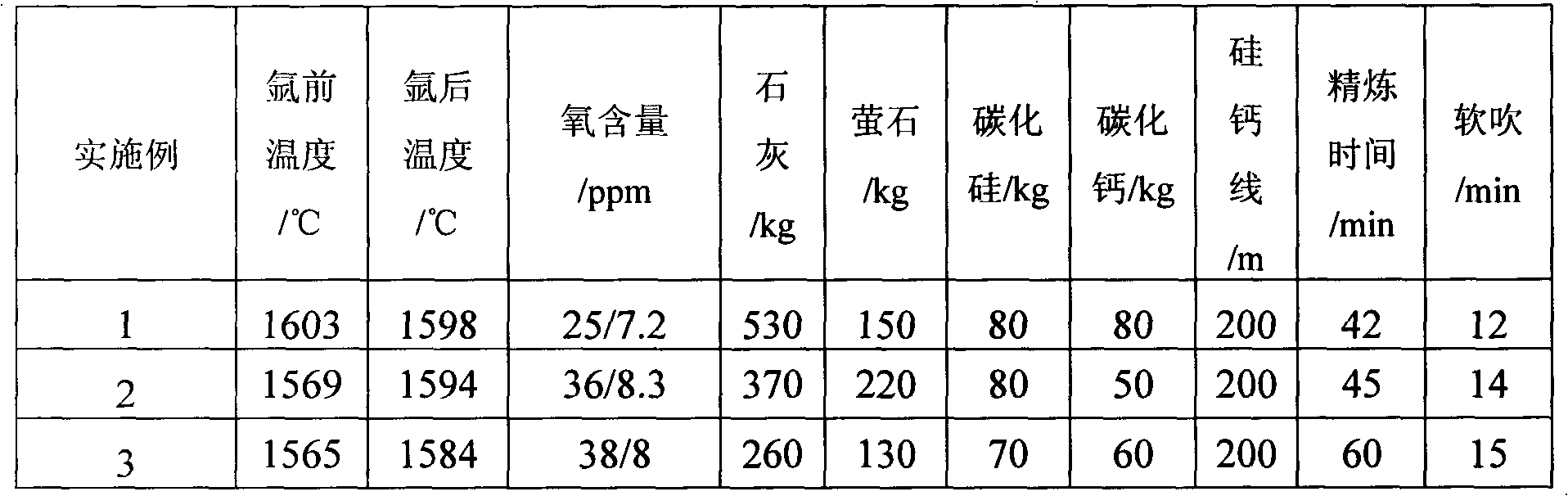

[0053] Table 3: Refining process record sheet

[0054]

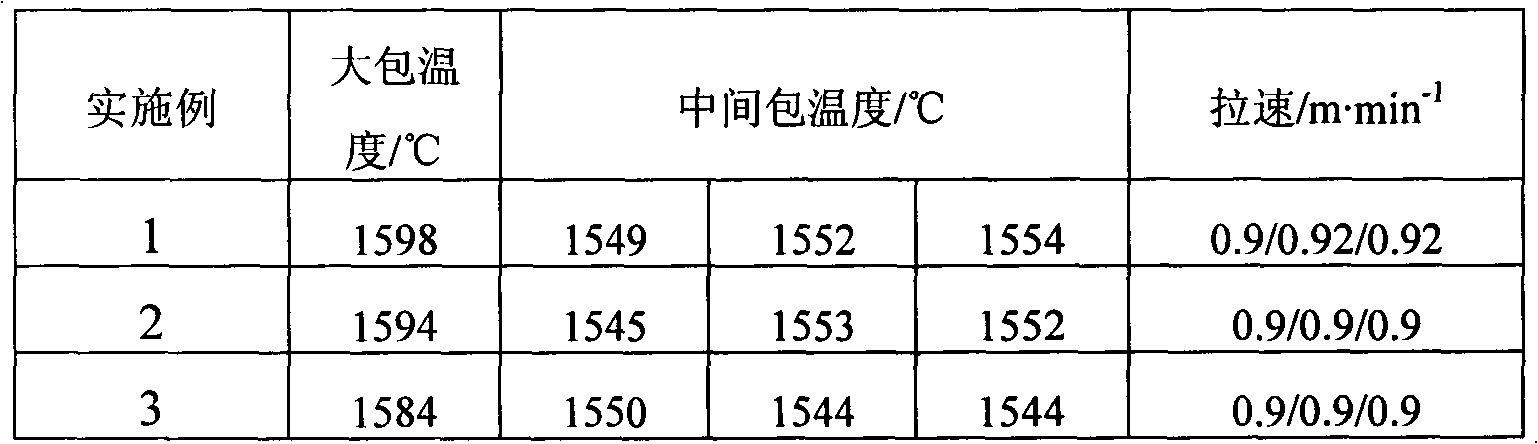

[0055] Table 4: Continuous casting process record sheet

[0056]

[0057] Table 5: Record table of mechanical properties of rolled products

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com