Double-shaft MEMS scanning-based heterodyne interference system and method

A technology of heterodyne interference and polarization direction, which is applied in the direction of measuring devices, instruments, and phase-influenced characteristic measurements, and can solve problems such as large vibration errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

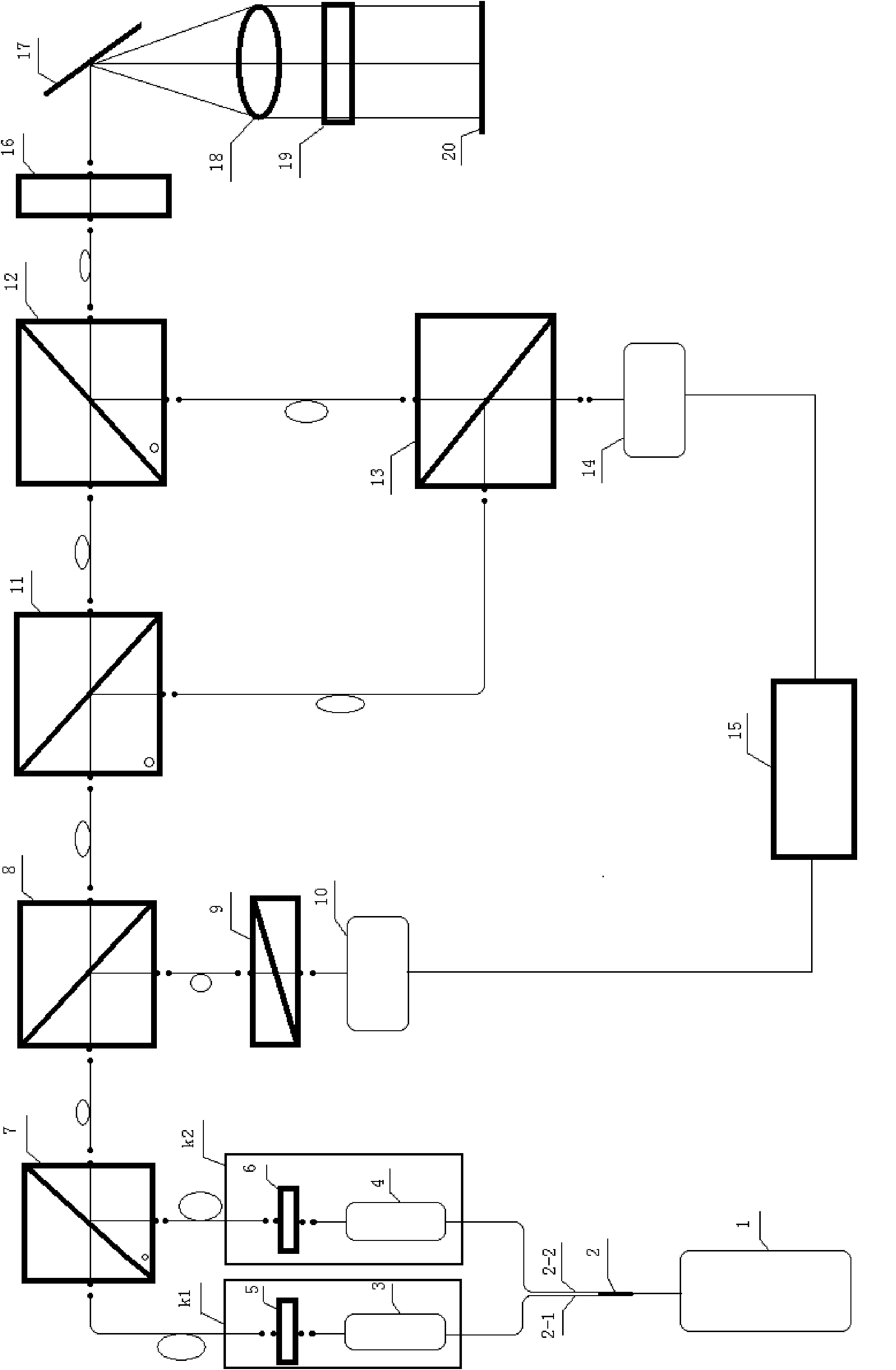

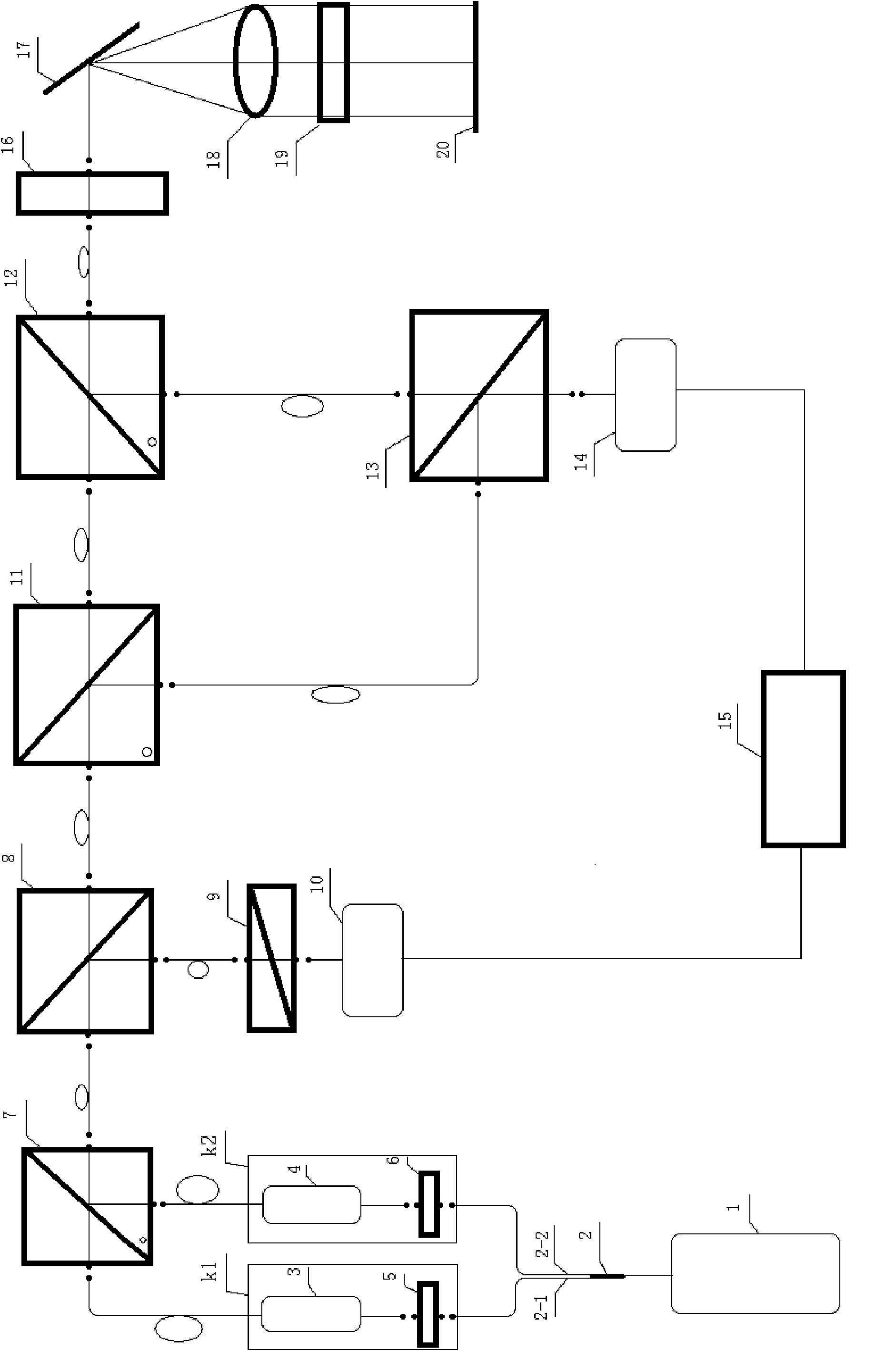

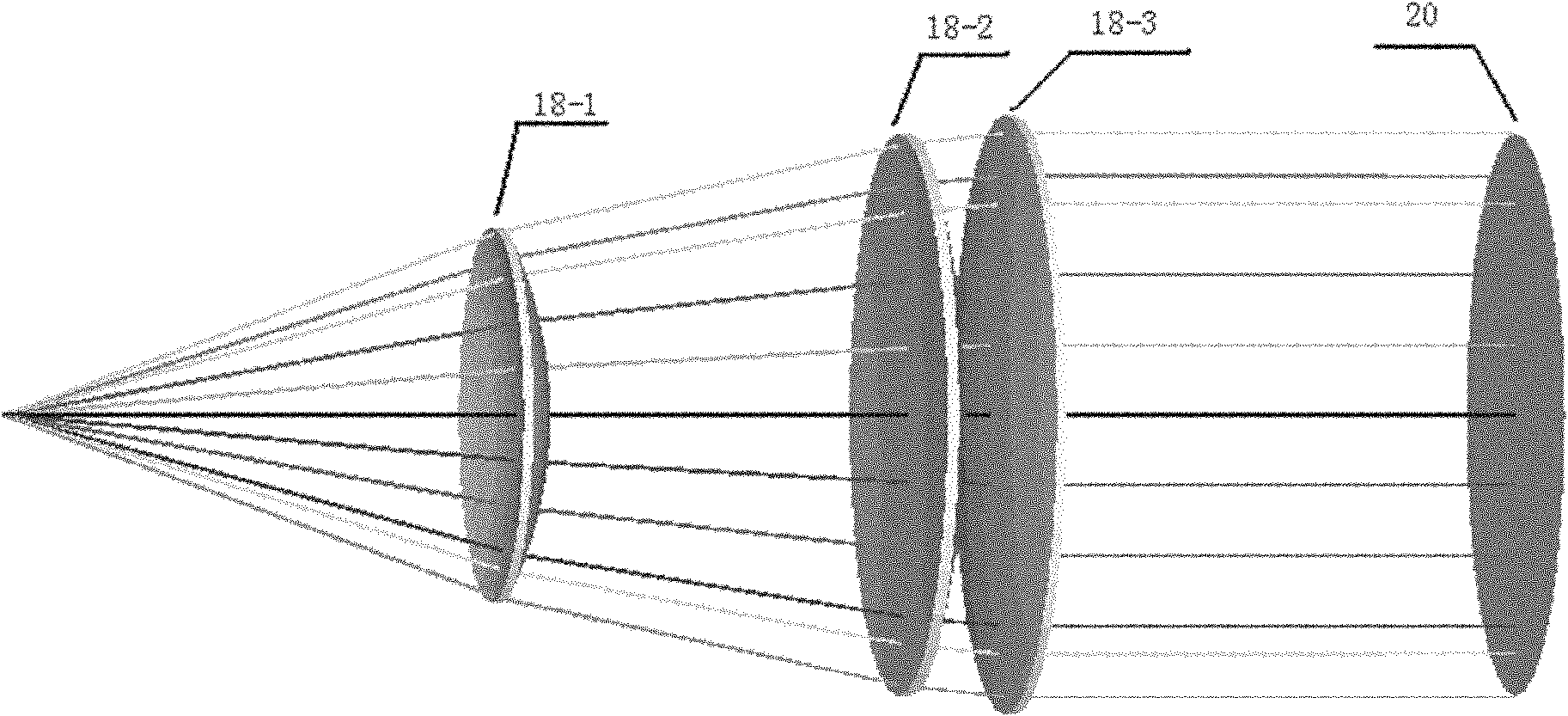

specific Embodiment approach 1

[0012] Specific implementation mode 1. Combination figure 1 with figure 2 Describe this embodiment, the heterodyne interferometry system of biaxial MEMS scanning, it comprises beam splitting prism 8, analyzer 9, first photodetector 10, second polarizing beam splitting prism 11, the 3rd polarizing beam splitting prism 12, Beam combining prism 13, second photodetector 14, computer 15, 1 / 4 wave plate 16, MEMS vibrating mirror 17, F-Theta lens group 18, sample cell 19 to be measured and mirror 20, beam splitting prism 8 will incident The light beam to its central position is split to form a reflected light beam and a transmitted light beam, wherein the reflected light beam is focused on the photosensitive surface of the first photodetector 10 after passing through the analyzer 9, and the signal output terminal of the first photodetector 10 is connected with the computer The first signal input end of 15 is connected, and the light beam transmitted by the second polarizing beam sp...

specific Embodiment approach 2

[0013] Specific embodiment two, combine figure 1 with figure 2 Describe this embodiment mode, this embodiment mode is the further explanation to specific embodiment one, the heterodyne interferometry system of biaxial MEMS scanning, it also comprises orthogonally polarized laser emitting system, and this orthogonally polarized laser emitting system comprises laser 1, optical fiber The beam splitter 2, the first polarization frequency shifting module k1, the second polarization frequency shifting module k2 and the first polarization beam splitting prism 7, the linearly polarized light emitted by the laser 1 enters the fiber beam splitter 2 and is divided into two branches , wherein the light beam of the first branch becomes the first linearly polarized light after passing through the first polarization frequency shifting module k1 and enters the first polarizing beam splitting prism 7, and the first linearly polarized light is transmitted through the first polarizing beam spli...

specific Embodiment approach 3

[0014] Embodiment 3. This embodiment is a further description of Embodiment 2. The laser 1 is a 2 μm laser.

[0015] The working wavelength of the laser 1 is in the 2 μm band which is safe for human eyes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com