Solvent composition for manufacturing laminated ceramic component

A solvent composition and lamination technology, which can be applied to laminated capacitors, parts of fuel cells, parts of fixed capacitors, etc., can solve the problems of prolonged time, reduced production efficiency, slow evaporation speed, etc. Effect, improvement of manufacturing efficiency, effect of shortening drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

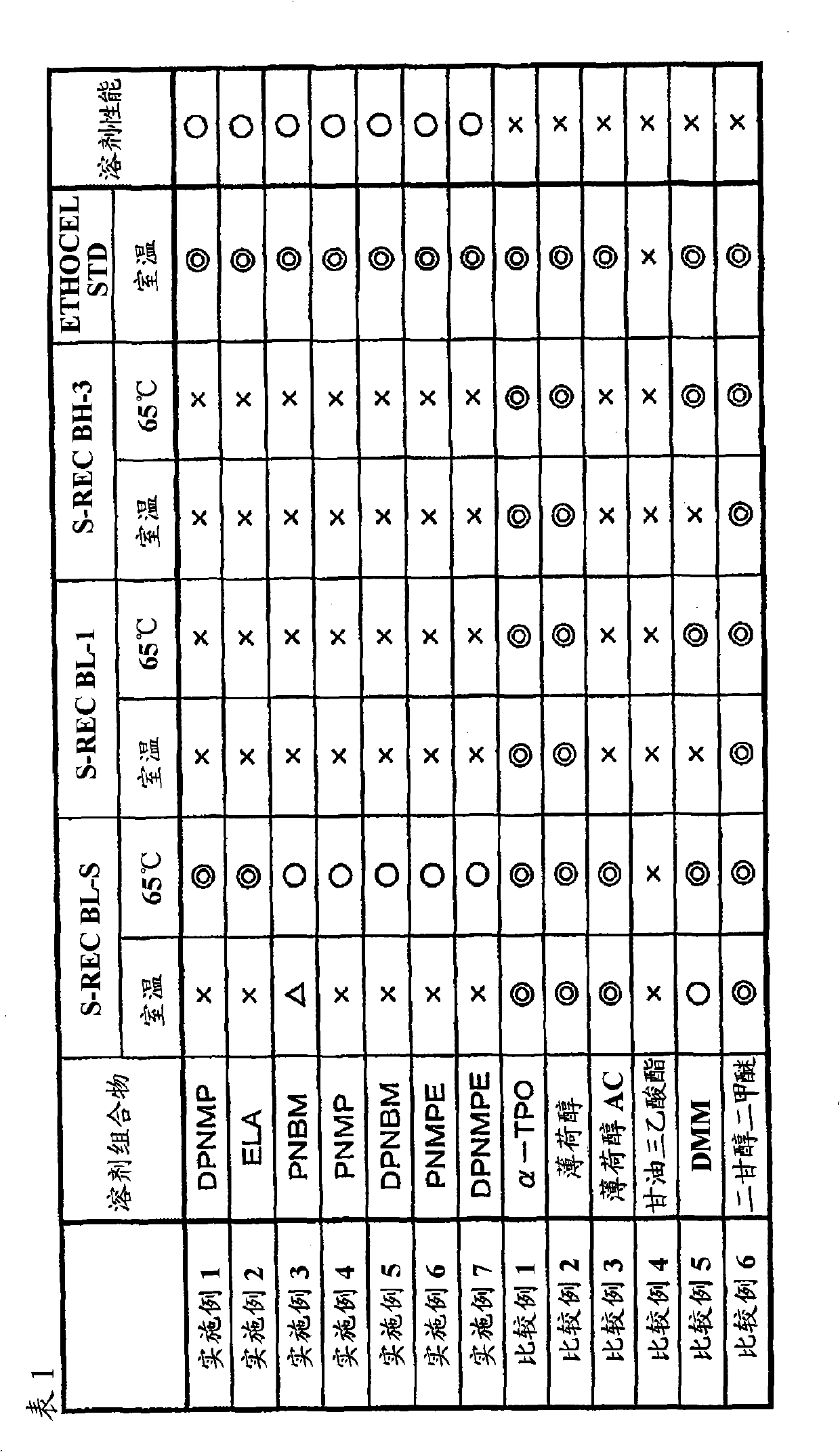

Embodiment 1~7、 comparative example 1~6

[0053] "S-REC BL-S" (trade name, manufactured by Sekisui Chemical Co., Ltd.), "S-REC BL-1" ( trade name, manufactured by Sekisui Chemical Co., Ltd.), "S-REC BH-3" (trade name, manufactured by Sekisui Chemical Co., Ltd.), and "ETHOCELSTD" (trade name, manufactured by Dow Chemical Co., Ltd.) which is ethyl cellulose production), the concentrations of these resins were respectively 5% by weight, heated and dissolved at a liquid temperature of 65° C. for 3 hours, and then cooled naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com