Water retaining material, preparation method thereof and application of water retaining material in filter rod

A technology of water-retaining materials and water-retaining capacity, applied in the fields of application, chemical instruments and methods, e-liquid filter elements, etc., can solve the problems of high production cost and discomfort, achieve high safety, simple preparation process, and improve selective adsorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Sieve the porous activated alumina to take 40-100 mesh particles, remove impurities, wash and soak, take 50ml (wet volume) and add it to 50-500ml 0.1%-10% polyvinyl alcohol alkali solution, that is The volume ratio of the two is 1:1-1:10, stirred at room temperature for 1-4h or ultrasonically oscillated for 10-60min, filtered, and vacuum-dried at 30-50°C for 0.5-1h to obtain water-retaining material 1.

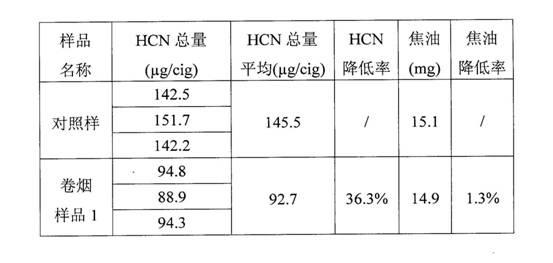

[0026] Apply the water-retaining material 1 to cigarettes in the form of binary composite filter rods, the addition amount is 35mg / cig, and it is marked as cigarette sample 1. The cigarette without any filter modification material is used as a control sample. (22±1)°C and relative humidity (60±2)% for 48 hours, and then sorted by weight (average weight ±0.02g) and suction resistance (average suction resistance ±49Pa) to pick out the test that meets the standard cigarette. The cigarette smoking test was carried out on a smoking machine according to the standard smoking ...

Embodiment 2

[0031] After washing and soaking the porous hydrophilic vinyl polymer HW-65F, take 50ml (wet volume) and add it to 50-500ml 0.1%-10% carboxymethyl starch alkali solution, that is, the volume ratio of the two is 1:1~1:10, stir at room temperature for 1-4h or ultrasonically oscillate for 10-60min, filter, and vacuum dry at 30-50°C for 0.5-1h to obtain water-retaining material 2.

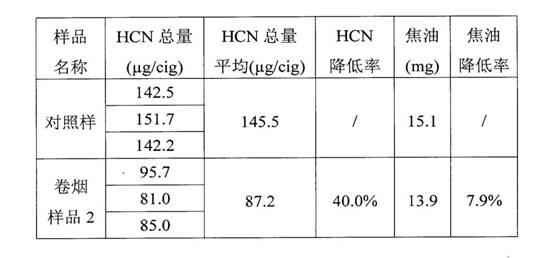

[0032] Apply the water-retaining material 2 to cigarettes in the form of binary composite filter rods, the added amount is 35 mg / cig, and it is marked as cigarette sample 2. The cigarette without any filter modification material is used as the control sample. (22±1)°C and relative humidity (60±2)% for 48 hours, and then sorted by weight (average weight ±0.02g) and suction resistance (average suction resistance ±49Pa) to pick out the test that meets the standard cigarette. The cigarette smoking test was carried out on a smoking machine according to the standard smoking conditions, and the release of hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com