Preparation method of battery-grade anhydrous lithium tetrafluoroborate

A lithium tetrafluoroborate, battery-grade technology, applied in the direction of boron halide compounds, etc., can solve the problem of high moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

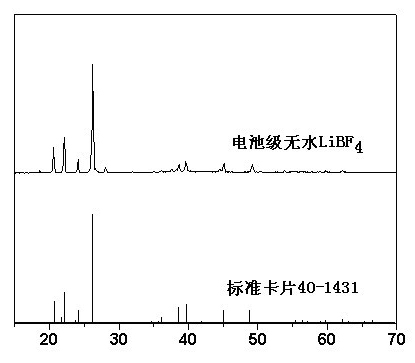

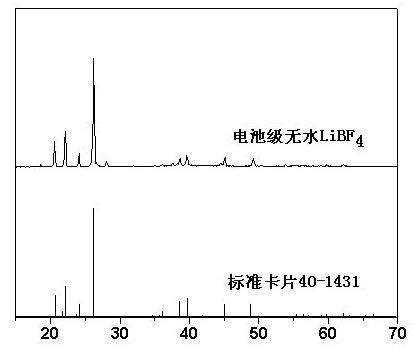

Image

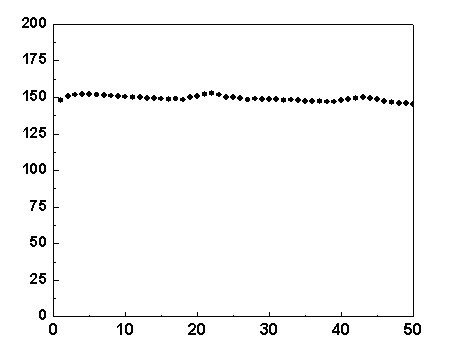

Examples

Embodiment 1

[0022] Weigh 427.4g of hydrofluoric acid with a mass fraction of 40%, slowly add 130.0g of boric acid while stirring in a cold water bath, and complete the addition within 1 hour. Stirring was continued for 1 hour, and 78.8 g of lithium carbonate was slowly added to the above solution to adjust the pH of the solution to be neutral, and the addition was completed within 1 hour. After filtering, the filtrate was evaporated and concentrated under infrared light until the lithium tetrafluoroborate content was about 70%. After the crystals were precipitated by cooling, the crystallization liquid was separated by filtration, the mother liquor was recovered, and the crystals were dried under an infrared lamp for about 4 hours to obtain a white powder.

[0023] Put the white powder into a glove box with circulating dry air, dissolve it with a small amount of absolute ethanol, and continue to dry it under an infrared lamp for 48 hours. The ethanol is completely evaporated to dryness to...

Embodiment 2

[0026] Weigh 427.4g of hydrofluoric acid with a mass fraction of 40%, slowly add 130.0g of boric acid while stirring in a cold water bath, and complete the addition within 1 hour. Stirring was continued for 1 hour, and about 89.6 g of lithium hydroxide monohydrate was slowly added to the above solution to adjust the pH of the solution to be neutral, and the addition was completed within 1 hour. After filtering, the filtrate was evaporated and concentrated under infrared light until the lithium tetrafluoroborate content was about 70%. After filtration, the mother liquor was recovered, and the solid was dried under an infrared lamp for about 4 hours to obtain a white powder.

[0027] Dissolve the white powder in absolute ethanol, and filter again to remove impurities. The filtrate was evaporated under infrared lamp for 12 hours to obtain white lithium tetrafluoroborate powder.

[0028] Put the white powder into a glove box with circulating dry air, dissolve it with a small amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com